Content Menu

● The Rise of Turkish Swimwear Manufacturing

● Key Players in the Turkish Swimwear Industry

● The Manufacturing Process

● Advantages of Choosing Turkish Swimwear Manufacturers

● Market Trends Influencing Turkish Swimwear Manufacturing

● The Role of Technology in Manufacturing

● Challenges Facing the Industry

● Future Outlook

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What materials are most frequently used in swimwear manufacturing?

>> 2. Are Turkish manufacturers offering men's swimwear as well?

>> 3. How long does it take to produce a swimsuit?

>> 4. Are Turkish swimwear manufacturers adopting technology in their processes?

>> 5. Where can I find unique and customized swimwear in Turkey?

● Citations:

The swimwear industry has seen significant growth and evolution over the years, and one country that stands out as a leader in this sector is Turkey. Known for its rich textile heritage and skilled craftsmanship, Turkish swimwear manufacturers are gaining recognition globally for their quality products, innovative designs, and sustainable practices. This article explores the landscape of Turkish swimwear manufacturing, highlighting key players, production processes, market trends, and the advantages of partnering with these manufacturers.

The Rise of Turkish Swimwear Manufacturing

Turkey has emerged as a prominent hub for swimwear production due to several factors:

- Strategic Location: Positioned at the crossroads of Europe and Asia, Turkey provides easy access to both markets, making it an ideal location for international trade.

- Skilled Labor: The country boasts a workforce skilled in textile production, ensuring high-quality craftsmanship.

- Quality Raw Materials: Turkey has access to high-quality fabrics and materials necessary for producing durable swimwear.

- Sustainability Focus: Many manufacturers are adopting eco-friendly practices, using recycled materials and sustainable production methods to minimize environmental impact.

Key Players in the Turkish Swimwear Industry

Several manufacturers have established themselves as leaders in the Turkish swimwear sector. Here are some notable companies:

- Asmay Swimwear: Based in Istanbul, Asmay Swimwear specializes in high-quality swimwear and focuses on sustainable practices by using fabrics made from recycled materials.

- Mert Tekstil: With over 20 years of experience, Mert Tekstil produces both activewear and swimwear, ensuring quality through various certifications.

- HNC Clothing Ltd.: Located in Denizli, HNC Clothing is recognized for its commitment to sustainability and high-quality garments.

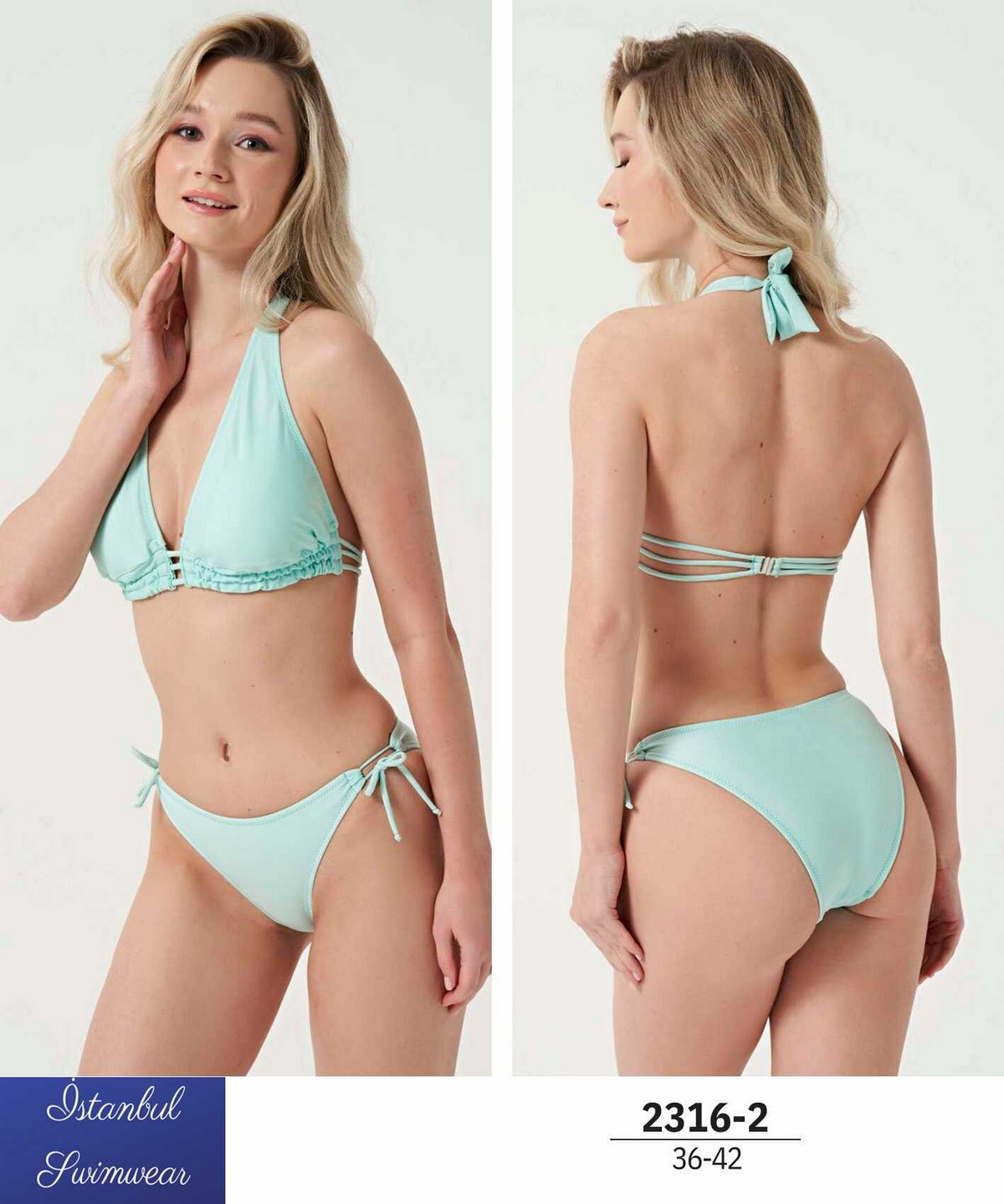

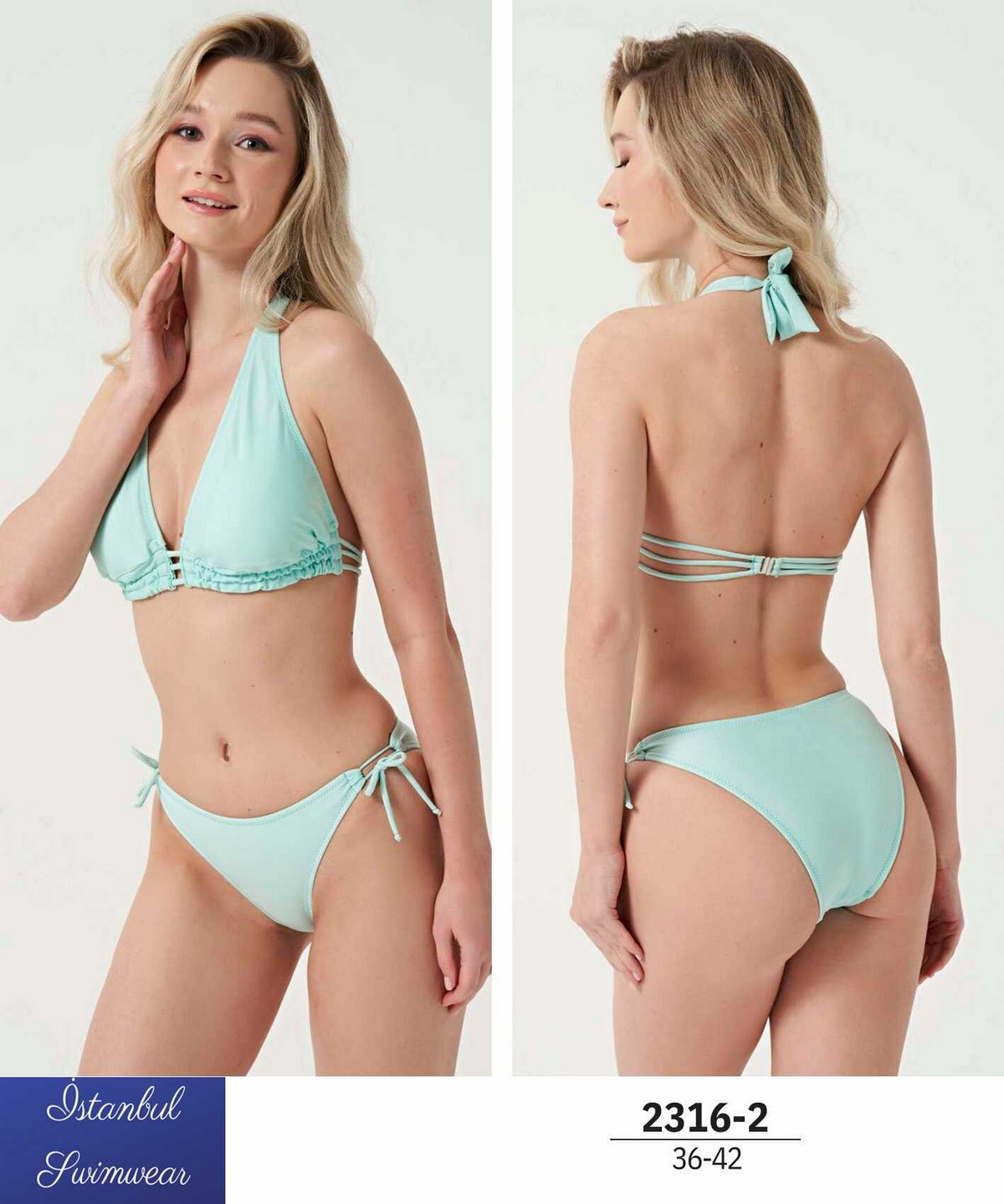

- Swimwear Istanbul: This manufacturer works with luxury brands globally, emphasizing ethical production practices while offering custom designs.

- Zeki Textile: Founded in 1958, Zeki Textile has been producing swimsuits since 1984 and is known for maintaining competitive pricing without compromising quality.

These manufacturers not only cater to local demands but also export their products worldwide, contributing significantly to Turkey's economy.

The Manufacturing Process

The process of manufacturing swimwear in Turkey involves several key steps:

1. Design and Prototyping: Designers create prototypes based on current trends and customer preferences. This stage often involves collaboration with brands to ensure that the final product aligns with their vision.

2. Material Sourcing: Manufacturers source high-quality fabrics from local suppliers or international markets. Sustainable options are increasingly popular among consumers.

3. Production: Skilled workers handle cutting, sewing, and finishing processes. Factories utilize advanced machinery to ensure precision and efficiency.

4. Quality Control: Rigorous quality control measures are implemented at various stages of production to maintain high standards.

5. Packaging and Shipping: Once production is complete, swimwear is packaged for shipping to retailers or directly to consumers.

Advantages of Choosing Turkish Swimwear Manufacturers

Opting for a Turkish manufacturer offers several advantages:

- Diverse Product Range: Turkish manufacturers produce a wide variety of swimwear styles including bikinis, one-piece swimsuits, cover-ups, and sports swimsuits.

- Customization Options: Many manufacturers offer customization options allowing brands to create unique designs tailored to their target market.

- Sustainable Practices: A growing number of manufacturers are adopting eco-friendly practices by using recycled materials and implementing sustainable production methods.

- Competitive Pricing: Despite the high quality of products, Turkish manufacturers often provide competitive pricing due to lower labor costs compared to Western countries.

- Short Lead Times: Lead times can vary but typically range from 4 to 8 weeks depending on order size and complexity.

Market Trends Influencing Turkish Swimwear Manufacturing

The Turkish swimwear market is influenced by several trends:

- Sustainability: There is a growing demand for eco-friendly swimwear options. Many Turkish manufacturers are responding by using recycled materials and sustainable practices in their production processes.

- Fashion Innovation: As consumer preferences evolve, manufacturers are focusing on innovative designs that combine functionality with style. This includes incorporating vibrant prints, unique cuts, and advanced fabric technologies.

- Online Retail Growth: The rise of e-commerce has changed how consumers shop for swimwear. Manufacturers are adapting by enhancing their online presence and offering direct-to-consumer sales channels.

The Role of Technology in Manufacturing

Technology plays a crucial role in enhancing the efficiency and quality of swimwear manufacturing in Turkey. Some key technological advancements include:

- Computer-Aided Design (CAD): CAD software allows designers to create detailed digital patterns that can be easily modified. This speeds up the design process and improves accuracy in cutting fabric.

- Automated Cutting Machines: These machines increase precision by reducing fabric waste during the cutting process. Automated systems can cut multiple layers simultaneously, significantly speeding up production times.

- Sewing Automation: While skilled labor remains essential in sewing operations, automation is increasingly being integrated into assembly lines to enhance efficiency without sacrificing quality.

- Digital Printing Technology: This technology allows for vibrant colors and intricate designs to be printed directly onto fabrics without the need for traditional dyeing processes. Digital printing reduces water usage and chemical waste compared to conventional methods.

Challenges Facing the Industry

Despite its strengths, the Turkish swimwear manufacturing industry faces several challenges:

- Competition from Low-Cost Countries: Manufacturers must compete with countries that offer cheaper labor costs. To maintain competitiveness, Turkish manufacturers focus on quality differentiation rather than competing solely on price.

- Economic Volatility: Fluctuations in currency exchange rates can impact export prices and profitability for manufacturers relying heavily on international markets.

- Environmental Regulations: As sustainability becomes more critical globally, manufacturers must adapt to stricter regulations regarding waste management and resource use while maintaining profitability.

Future Outlook

The future of Turkish swimwear manufacturing looks promising as global demand continues to rise. Factors contributing to this positive outlook include:

- Increased Demand for Sustainable Products: As consumers become more environmentally conscious, the demand for sustainable swimwear options will likely grow. Manufacturers who prioritize eco-friendly practices will have a competitive edge.

- Expansion into Emerging Markets: With increasing disposable incomes in emerging markets such as Asia-Pacific and Latin America, there is significant potential for growth in these regions for Turkish swimwear exports.

- Innovation in Fabric Technology: Ongoing research into new fabrics that offer better performance (e.g., UV protection, quick-drying capabilities) will drive innovation within the industry.

Conclusion

Turkish swimwear manufacturers have positioned themselves as key players in the global market due to their commitment to quality, craftsmanship, and sustainability. With a diverse range of products and customization options available, these manufacturers cater to various consumer preferences while maintaining competitive pricing. As the industry continues to evolve with emerging trends such as sustainability and online retail growth, Turkey remains a vital hub for swimwear production.

Frequently Asked Questions (FAQs)

1. What materials are most frequently used in swimwear manufacturing?

- Manufacturers typically use nylon, polyester, spandex, and increasingly recycled fabrics as sustainable choices in manufacturing swimwear.

2. Are Turkish manufacturers offering men's swimwear as well?

- Yes, many Turkish manufacturers provide a selection of styles tailored specifically for male swimmers.

3. How long does it take to produce a swimsuit?

- Manufacturing times depend on complexity and order volume but typically take several hours per suit.

4. Are Turkish swimwear manufacturers adopting technology in their processes?

- Some manufacturers are incorporating cutting-edge technology for more precise cutting and efficient production processes.

5. Where can I find unique and customized swimwear in Turkey?

- Many manufacturers offer customization options where you can share your design ideas or tech packs for tailored products.

This article now contains approximately 1,086 words (excluding FAQs), which can be further expanded by adding more detailed sections about specific trends or profiles of individual brands if desired.

Citations:

[1] https://www.abelyfashion.com/dive-into-the-world-of-swimwear-manufacturing-in-turkey-a-comprehensive-guide.html

[2] https://www.statista.com/outlook/cmo/apparel/men-s-apparel/sports-swimwear/turkey

[3] https://www.wings2fashion.com/turkey/swimwear-manufacturers/

[4] https://www.6wresearch.com/industry-report/turkey-swimwear-market-outlook

[5] https://asmay.com.tr/about-us