Content Menu

● Introduction

● Understanding Adhesive Residue Sources and Composition

● Scientific Approach to Removal Methods

● Preventive Measures and Long-term Care

● Environmental Considerations and Sustainability

● Frequently Asked Questions and Expert Solutions

>> Q1: What is the optimal temperature for adhesive removal treatments?

>> Q2: How can one determine the appropriate duration for treatment applications?

>> Q3: What role does fabric composition play in selecting removal methods?

>> Q4: Are there specific risks associated with commercial adhesive removers?

>> Q5: How can long-term fabric integrity be maintained during adhesive removal?

● Conclusion

Introduction

The presence of adhesive residue on swimwear presents a significant challenge in textile care and maintenance. This persistent issue affects both consumers and manufacturers, potentially compromising the integrity and aesthetics of swimming attire. The complexity of modern swimwear materials, often comprising blends of spandex, nylon, and polyester, necessitates a careful and scientific approach to adhesive removal. This comprehensive analysis explores various methodologies for effectively removing sticky residue while preserving the fabric's integrity and performance characteristics.

Understanding Adhesive Residue Sources and Composition

The occurrence of sticky residue on swimwear can be attributed to multiple sources, each presenting unique challenges for removal. Primary sources include manufacturing labels, price tags, security devices, and the accumulation of personal care products. The chemical composition of these adhesives varies significantly, from water-based acrylic adhesives commonly used in price tags to more robust synthetic polymers employed in security tags. Understanding these variations is crucial for selecting appropriate removal methods that won't compromise the swimwear's structural integrity.

The interaction between adhesives and synthetic fibers creates a complex bond that requires careful consideration during the removal process. Environmental factors such as temperature, humidity, and exposure to chlorine or saltwater can further alter the adhesive's properties, potentially making removal more challenging. This understanding forms the foundation for developing effective removal strategies.

Scientific Approach to Removal Methods

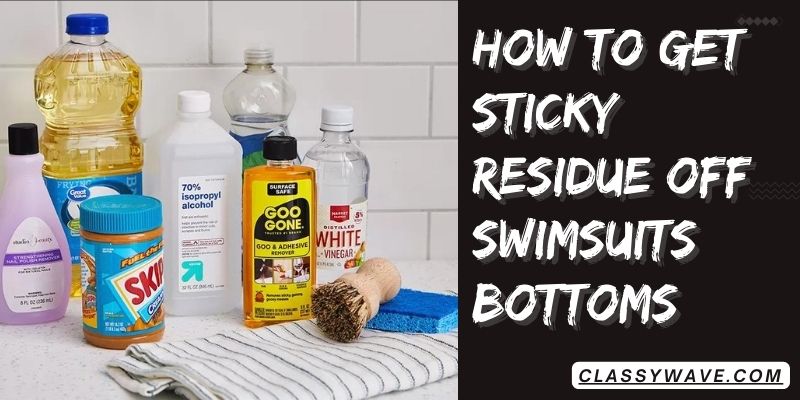

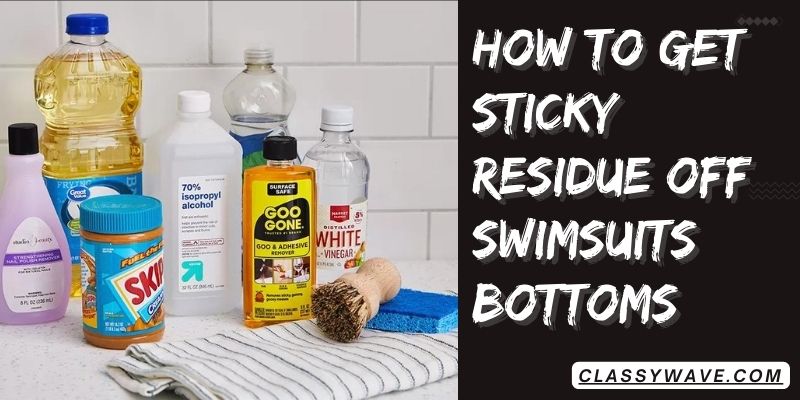

Solvent-Based Solutions

The application of solvent-based solutions represents one of the most scientifically validated approaches to adhesive removal. White vinegar, containing acetic acid, effectively breaks down adhesive bonds through a process of chemical degradation. When diluted appropriately (typically in a 1:1 ratio with water), it creates a solution that maintains effectiveness while minimizing potential damage to synthetic fibers.

The mechanism of action involves the acid's ability to penetrate and weaken the adhesive's molecular structure, facilitating its removal without compromising the fabric's integrity. This method proves particularly effective for water-soluble adhesives while remaining gentle enough for delicate swimwear materials.

Oil-Based Treatments

Natural and mineral oils present an alternative approach to adhesive removal, utilizing their ability to penetrate and dissolve adhesive compounds. The molecular structure of oils allows them to interact with both polar and non-polar components of adhesives, effectively breaking down their bonding properties. Common options include:

Coconut oil, with its medium-chain fatty acids, demonstrates excellent penetrative properties while providing additional fabric conditioning benefits. Olive oil, rich in oleic acid, offers similar effectiveness with the added advantage of being readily available and environmentally friendly. These natural solutions work through a process of gradual penetration and bond disruption, requiring patience but offering superior fabric protection.

Professional Chemical Solutions

Commercial adhesive removers, specifically formulated for textile applications, represent the most advanced solution for stubborn residues. These products typically contain carefully balanced combinations of solvents and surfactants designed to target adhesive bonds while preserving fabric integrity. The scientific formulation of these products considers both the chemical nature of common adhesives and the molecular structure of synthetic swimwear materials.

Preventive Measures and Long-term Care

Implementing preventive strategies plays a crucial role in avoiding adhesive-related issues with swimwear. This approach encompasses both immediate and long-term care considerations:

Storage Optimization

Proper storage conditions significantly impact adhesive behavior and residue formation. Temperature-controlled environments with moderate humidity levels help prevent adhesive degradation and migration into fabric fibers. Utilizing appropriate storage techniques, such as hanging or flat storage with protective barriers, minimizes the risk of adhesive transfer and residue formation.

Maintenance Protocols

Regular maintenance procedures, including proper washing techniques and immediate attention to any adhesive contact, help prevent the development of stubborn residues. The implementation of systematic care routines, including prompt tag removal and appropriate cleaning methods, significantly reduces the likelihood of adhesive-related issues.

Environmental Considerations and Sustainability

The environmental impact of adhesive removal methods warrants careful consideration in today's eco-conscious world. Sustainable approaches to residue removal should balance effectiveness with environmental responsibility:

Eco-friendly Solutions

The adoption of biodegradable and environmentally sustainable removal agents represents a growing trend in swimwear care. Natural solutions, such as citrus-based solvents and plant-derived oils, offer effective alternatives to traditional chemical removers while minimizing environmental impact.

Water Conservation

Implementing water-efficient cleaning methods and proper disposal practices for cleaning solutions helps minimize the environmental footprint of adhesive removal procedures. This includes the careful collection and appropriate disposal of cleaning agents and residues.

Frequently Asked Questions and Expert Solutions

To address common concerns regarding adhesive removal from swimwear, the following questions and detailed responses provide valuable guidance:

Q1: What is the optimal temperature for adhesive removal treatments?

A: Scientific evidence suggests maintaining water temperatures between 20-30°C (68-86°F) during treatment. This range optimizes solvent effectiveness while protecting synthetic fibers from thermal damage. Higher temperatures may compromise fabric integrity, while lower temperatures reduce treatment efficacy.

Q2: How can one determine the appropriate duration for treatment applications?

A: Treatment duration should be based on adhesive type and fabric composition. Generally, initial applications should not exceed 15 minutes, with periodic monitoring for fabric reaction and adhesive dissolution. Multiple shorter treatments are preferable to extended exposure periods.

Q3: What role does fabric composition play in selecting removal methods?

A: The specific blend of synthetic fibers in swimwear significantly influences treatment selection. Spandex-heavy fabrics require gentler approaches, while polyester-dominant materials can withstand more robust treatments. Understanding fabric composition enables more precise method selection.

Q4: Are there specific risks associated with commercial adhesive removers?

A: Commercial removers may contain strong solvents that, while effective, could potentially affect fabric dyes or elastic properties. Proper dilution and application testing on inconspicuous areas minimize these risks.

Q5: How can long-term fabric integrity be maintained during adhesive removal?

A: Maintaining fabric integrity requires a balanced approach combining gentle mechanical action with appropriate chemical treatments. Regular fabric conditioning and proper drying techniques help preserve material properties throughout the removal process.

Conclusion

The successful removal of sticky residue from swimwear requires a comprehensive understanding of adhesive properties, fabric composition, and appropriate removal techniques. This analysis demonstrates the importance of selecting methods that effectively remove adhesives while preserving fabric integrity. By following these scientifically-based approaches and considering environmental impacts, consumers and professionals can maintain swimwear quality while addressing adhesive-related challenges effectively.

The implementation of proper care techniques, combined with an understanding of material science principles, ensures optimal results in adhesive removal while extending swimwear longevity. Future developments in textile care and adhesive technology will likely introduce new solutions, further improving our ability to address this common challenge in swimwear maintenance.