Content Menu

● The Global Swimwear Market: A Growing Industry

● Key Players in the Swimwear Manufacturing Industry

● The Design Process: Where Creativity Meets Functionality

● Material Selection: The Foundation of Quality Swimwear

● The Manufacturing Process: From Fabric to Finished Product

● Innovations in Swimwear Manufacturing

● Sustainability in Swimwear Manufacturing

● Challenges Facing Swimwear Manufacturers

● The Future of Swimwear Manufacturing

● The Role of E-commerce in Swimwear Manufacturing

● Conclusion

In the ever-evolving landscape of fashion, swimwear manufacturers play a crucial role in shaping the way we enjoy our time by the water. From sun-soaked beaches to luxurious poolsides, the products created by these innovative companies are essential for both leisure and competitive swimming. This comprehensive exploration delves into the intricate world of swimwear manufacturers, examining the industry's trends, production processes, and the challenges they face in today's dynamic market.

The Global Swimwear Market: A Growing Industry

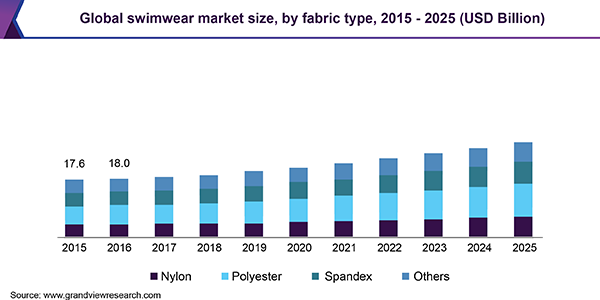

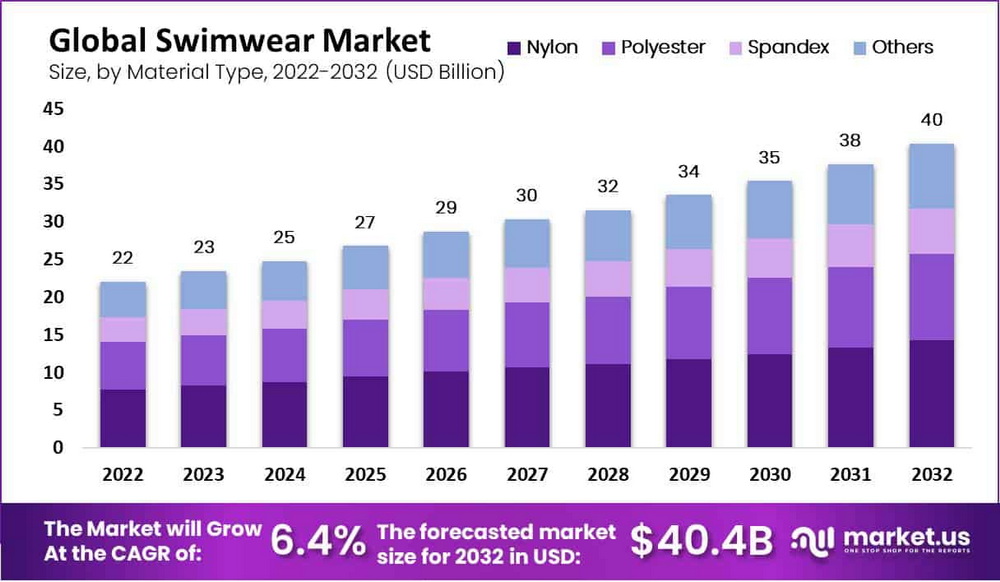

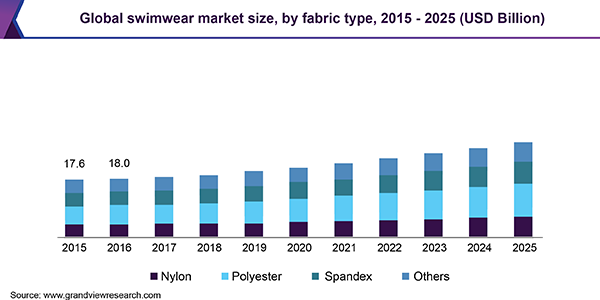

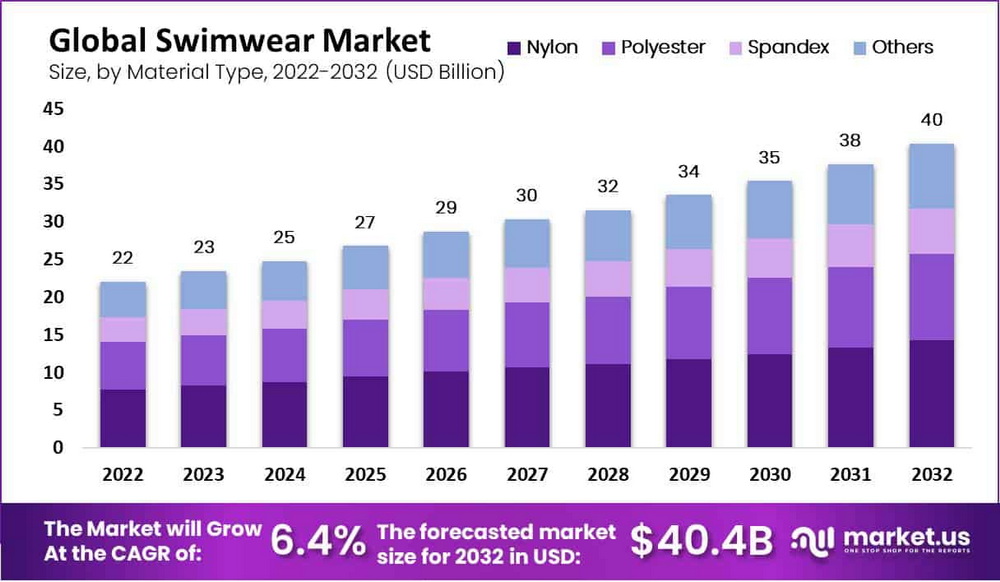

The swimwear industry has experienced significant growth in recent years, with swimwear manufacturers at the forefront of this expansion. As more people embrace beach vacations, water sports, and fitness activities, the demand for high-quality, stylish swimwear continues to rise. This trend has created a fertile ground for both established swimwear manufacturers and newcomers to the industry.

Swimwear manufacturers are constantly adapting to meet the changing needs and preferences of consumers worldwide. From traditional one-piece suits to innovative designs that blur the lines between swimwear and everyday fashion, these companies are pushing the boundaries of what's possible in aquatic apparel.

Key Players in the Swimwear Manufacturing Industry

The swimwear manufacturing landscape is diverse, with companies ranging from small, boutique operations to large-scale international producers. Some of the most prominent swimwear manufacturers have been in the business for decades, building a reputation for quality and innovation. These industry leaders often set the trends that smaller manufacturers follow, influencing the direction of swimwear design and production on a global scale.

However, the rise of sustainable and eco-friendly practices has also given birth to a new generation of swimwear manufacturers. These companies focus on using recycled materials and environmentally conscious production methods, catering to the growing demand for sustainable fashion options. As a result, the industry is seeing a blend of traditional manufacturing techniques and cutting-edge, eco-friendly innovations.

The Design Process: Where Creativity Meets Functionality

For swimwear manufacturers, the journey from concept to finished product begins with the design process. This crucial stage involves a delicate balance between aesthetic appeal and practical functionality. Designers working for swimwear manufacturers must consider various factors, including current fashion trends, consumer preferences, and the specific requirements of different water-based activities.

The design phase often starts with extensive market research. Swimwear manufacturers analyze sales data, consumer feedback, and emerging fashion trends to inform their design decisions. This research helps them identify gaps in the market and opportunities for innovation. Designers then create sketches and digital renderings of potential swimwear designs, considering factors such as silhouette, color palettes, and fabric choices.

Once initial designs are approved, swimwear manufacturers move on to the prototyping stage. This involves creating sample pieces that can be tested for fit, comfort, and durability. The prototyping process is crucial for identifying any potential issues with the design before moving into full-scale production. Swimwear manufacturers often conduct multiple rounds of prototyping and testing to ensure that their products meet the highest standards of quality and performance.

Material Selection: The Foundation of Quality Swimwear

One of the most critical decisions swimwear manufacturers face is the selection of materials. The choice of fabric can significantly impact the performance, durability, and comfort of the final product. Traditional swimwear materials include nylon, polyester, and spandex, each offering unique properties that make them suitable for use in aquatic environments.

Nylon, for example, is prized by swimwear manufacturers for its strength, elasticity, and quick-drying properties. Polyester, on the other hand, is known for its resistance to chlorine and UV rays, making it an excellent choice for swimwear that will be exposed to harsh pool chemicals or intense sunlight. Spandex, also known as elastane, is often blended with other materials to provide the stretch and shape retention that is essential for comfortable, well-fitting swimwear.

In recent years, swimwear manufacturers have also begun exploring innovative, eco-friendly materials. Recycled polyester, made from post-consumer plastic bottles, has gained popularity as a sustainable alternative to virgin polyester. Some manufacturers are even experimenting with biodegradable fabrics, aiming to reduce the environmental impact of swimwear production and disposal.

The Manufacturing Process: From Fabric to Finished Product

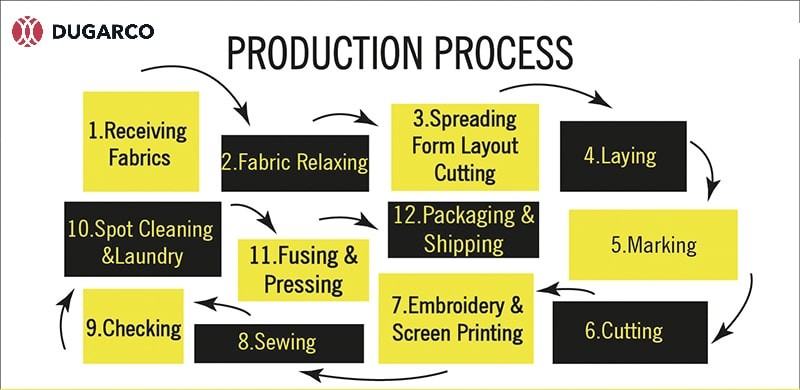

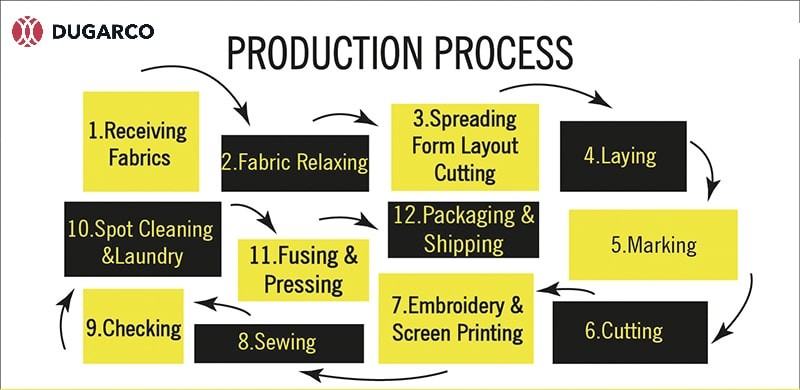

Once the design is finalized and materials are selected, swimwear manufacturers begin the production process. This typically involves several stages, each requiring specialized equipment and skilled workers.

The first step is often cutting the fabric according to the design patterns. Many swimwear manufacturers use computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to ensure precision and minimize waste. The cut pieces are then sorted and prepared for assembly.

Sewing is a critical stage in the manufacturing process. Swimwear manufacturers employ skilled seamstresses who use specialized sewing machines to join the fabric pieces together. The type of stitching used can vary depending on the design and the level of stretch required. Overlock stitches, for example, are commonly used in swimwear manufacturing to create strong, flexible seams that can withstand the stress of repeated wear and exposure to water.

After the basic construction is complete, swimwear manufacturers often add additional features such as underwire support, padding, or decorative elements. These components are carefully integrated into the garment to ensure both functionality and aesthetic appeal.

Quality control is an essential part of the manufacturing process. Swimwear manufacturers typically conduct thorough inspections at various stages of production to identify and correct any defects. This may include checks for proper stitching, color consistency, and overall fit and appearance.

The final stages of production involve adding any necessary labels, tags, or packaging. Many swimwear manufacturers take great care in creating attractive, informative packaging that enhances the perceived value of their products and provides consumers with important care instructions.

Innovations in Swimwear Manufacturing

The swimwear industry is constantly evolving, and manufacturers are at the forefront of innovation. One area of significant development is in the realm of performance fabrics. Swimwear manufacturers are investing in research and development to create materials that offer enhanced UV protection, improved chlorine resistance, and better moisture-wicking properties.

Another trend in swimwear manufacturing is the use of digital printing technologies. These advanced printing methods allow for more intricate and vibrant designs, giving manufacturers the ability to create unique, eye-catching patterns that were previously difficult or impossible to achieve with traditional printing techniques.

3D body scanning and virtual fitting technologies are also beginning to make their mark in the swimwear manufacturing industry. These tools allow manufacturers to create more accurate sizing and improve the fit of their products, potentially reducing returns and increasing customer satisfaction.

Sustainability in Swimwear Manufacturing

As environmental concerns continue to grow, many swimwear manufacturers are placing a greater emphasis on sustainability. This shift towards eco-friendly practices is evident in various aspects of the manufacturing process.

One key area of focus is the use of recycled materials. Many swimwear manufacturers are now incorporating fabrics made from recycled plastic bottles or fishing nets into their products. This not only reduces waste but also helps to address the issue of plastic pollution in our oceans.

Water conservation is another important consideration for swimwear manufacturers. Traditional textile dyeing processes can be water-intensive, so some companies are exploring waterless dyeing technologies or digital printing methods that significantly reduce water usage.

Energy efficiency is also on the radar of forward-thinking swimwear manufacturers. Some are investing in renewable energy sources to power their production facilities, while others are implementing energy-saving measures throughout their operations.

Challenges Facing Swimwear Manufacturers

Despite the industry's growth and innovations, swimwear manufacturers face several challenges. One of the most significant is the seasonal nature of the business. Demand for swimwear tends to peak during the summer months in many regions, which can lead to production bottlenecks and inventory management issues.

Competition is another major challenge. With the rise of fast fashion and online retail, swimwear manufacturers are under pressure to produce trendy designs quickly and at competitive prices. This can sometimes lead to compromises in quality or working conditions, issues that responsible manufacturers must navigate carefully.

The global nature of the swimwear industry also presents challenges related to supply chain management and international trade regulations. Swimwear manufacturers must often coordinate complex networks of suppliers, production facilities, and distribution channels across multiple countries.

The Future of Swimwear Manufacturing

Looking ahead, the future of swimwear manufacturing appears bright, albeit with continued evolution. As technology advances, we can expect to see even more innovative materials and production techniques emerge. Smart textiles that can monitor UV exposure or adjust to water temperature may become more common in high-end swimwear.

Customization is likely to play a larger role in the industry as well. With advancements in on-demand manufacturing and 3D printing, swimwear manufacturers may be able to offer more personalized products tailored to individual body shapes and preferences.

Sustainability will undoubtedly remain a key focus for swimwear manufacturers. We may see increased use of bio-based materials, closed-loop recycling systems, and even more emphasis on ethical production practices.

The Role of E-commerce in Swimwear Manufacturing

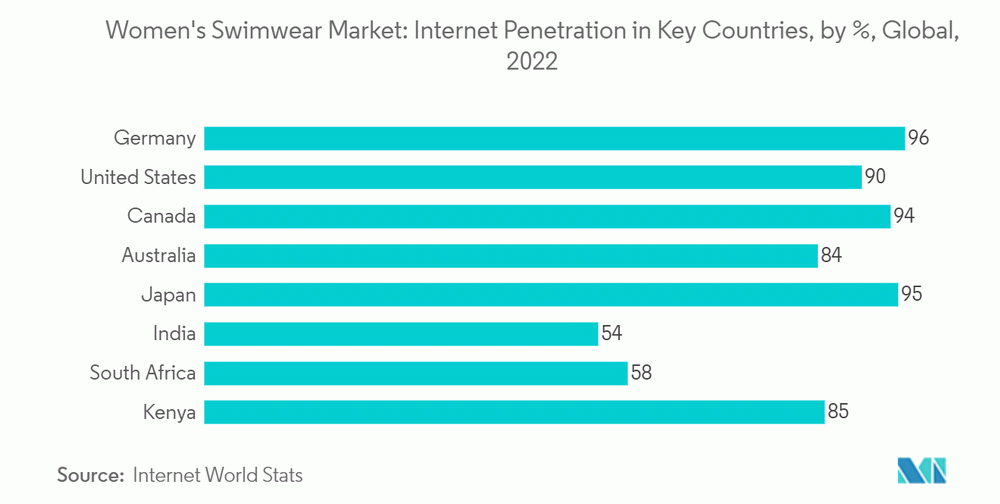

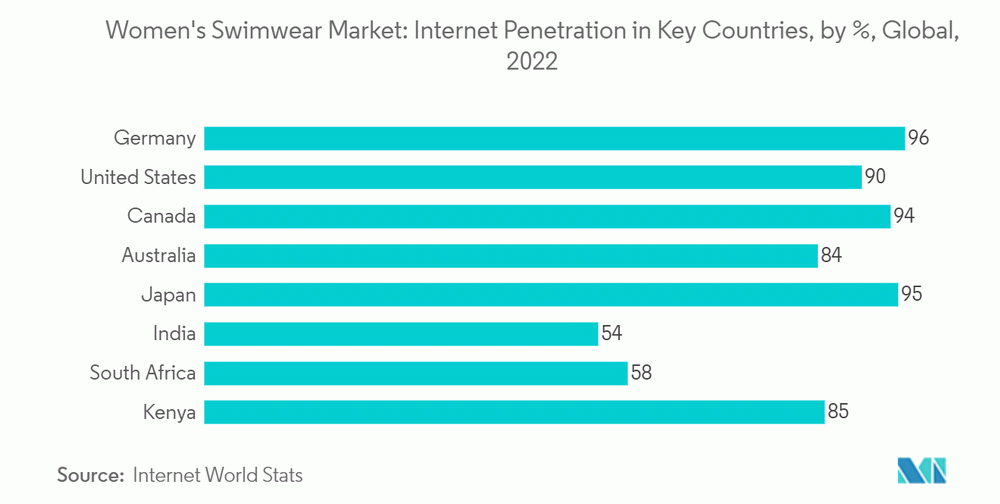

The rise of e-commerce has significantly impacted the swimwear manufacturing industry. Online retail platforms have opened up new opportunities for swimwear manufacturers to reach global markets directly. This has led to changes in production and distribution strategies, with many manufacturers adapting their processes to accommodate direct-to-consumer sales.

E-commerce has also influenced the way swimwear manufacturers approach marketing and customer engagement. Social media platforms have become crucial channels for showcasing new designs and building brand loyalty. Many swimwear manufacturers now collaborate with influencers and use user-generated content to promote their products, creating a more interactive and personalized shopping experience for consumers.

Conclusion

The world of swimwear manufacturing is a dynamic and multifaceted industry that combines creativity, technical expertise, and business acumen. From the initial design concept to the final product on store shelves or in online catalogs, swimwear manufacturers navigate a complex landscape of fashion trends, material innovations, and production challenges.

As we look to the future, it's clear that swimwear manufacturers will continue to play a vital role in shaping how we experience and enjoy water-based activities. Whether through sustainable practices, technological innovations, or creative design, these companies are constantly pushing the boundaries of what's possible in swimwear.

The success of swimwear manufacturers ultimately lies in their ability to balance form and function, creating products that not only look great but also perform well in the water. As consumer preferences evolve and new technologies emerge, the most successful swimwear manufacturers will be those that can adapt quickly while maintaining a commitment to quality and innovation.

In this ever-changing landscape, one thing remains constant: the enduring appeal of well-designed, high-quality swimwear. As long as people continue to seek out beaches, pools, and other aquatic environments for relaxation and recreation, swimwear manufacturers will be there to meet their needs, one stylish and functional piece at a time.