Content Menu

● The Rise of China's Swimwear Industry

● The Design Process: Where Creativity Meets Practicality

● Material Innovation: The Fabric of Success

● The Manufacturing Process: Precision at Scale

● Customization and Small Batch Production

● Sustainability: A Growing Priority

● Quality Control and Compliance

● The Export Process: From Factory to Global Markets

● Challenges and Future Outlook

● Conclusion

● Frequently Asked Questions

>> 1. Q: What makes China a leading country in swimwear manufacturing?

>> 2. Q: How do China's swimwear manufacturers incorporate sustainability into their processes?

>> 3. Q: What services do China's swimwear manufacturers typically offer beyond production?

>> 4. Q: How do China's swimwear manufacturers ensure quality control?

>> 5. Q: Can small brands or independent designers work with China's swimwear manufacturers?

In the world of fashion, few garments capture the essence of summer and leisure quite like swimwear. Behind the scenes of every stunning bikini or sleek one-piece lies a complex journey from initial concept to the final product gracing coastlines around the globe. At the heart of this process are China's swimwear manufacturers, who have established themselves as global leaders in turning creative visions into reality. This article will dive deep into the intricate world of swimwear production in China, exploring how these manufacturers bring designs to life with unparalleled expertise and efficiency.

The Rise of China's Swimwear Industry

China has long been recognized as the world's factory, but its dominance in swimwear manufacturing is particularly noteworthy. The country's swimwear industry has flourished over the past few decades, driven by a combination of factors including skilled labor, advanced technology, and a robust supply chain. Today, China's swimwear manufacturers are renowned for their ability to produce high-quality products at competitive prices, making them the go-to choice for brands worldwide.

One of the most remarkable aspects of China's swimwear manufacturing prowess is its concentration in specific regions. For instance, the city of Xingcheng in Liaoning province has earned the title of "Swimwear Capital" due to its significant contribution to the industry. With a population of around 500,000, it's astounding that nearly a third of Xingcheng's residents are involved in swimwear production. This concentration of expertise has led to the city accounting for a substantial 40% of China's swimwear market, with over 90% of its production being exported and contributing to more than 25% of the global supply.

The Design Process: Where Creativity Meets Practicality

The journey of a swimwear piece begins long before it reaches the factory floor. It starts with a spark of inspiration, often drawn from current fashion trends, cultural influences, or innovative material technologies. China's swimwear manufacturers have developed a keen sense for global fashion trends, allowing them to offer valuable input during the design phase.

Many china swimwear manufacturers now offer comprehensive design services, working closely with brands to refine concepts and ensure they are both aesthetically pleasing and technically feasible. This collaborative approach often involves:

1. Trend Analysis: Researching global fashion trends and consumer preferences to inform design decisions.

2. Material Selection: Choosing the right fabrics that balance style, comfort, and performance.

3. Pattern Making: Creating precise patterns that will translate well to the human form.

4. 3D Modeling: Utilizing advanced software to visualize designs before physical prototyping.

5. Sustainability Considerations: Incorporating eco-friendly materials and production methods to meet growing consumer demand for sustainable fashion.

The use of virtual 3D sampling has become increasingly popular among china swimwear manufacturers. This technology allows for rapid prototyping and iteration, reducing the time and resources needed to finalize a design. It also enables brands to visualize how a swimsuit will look and move on different body types, ensuring a better fit for a diverse range of consumers.

Material Innovation: The Fabric of Success

The choice of fabric is crucial in swimwear design, as it must withstand the harsh conditions of sun, salt, and chlorine while providing comfort and style. China's swimwear manufacturers have been at the forefront of material innovation, working with advanced textiles that offer properties such as:

- UV protection

- Chlorine resistance

- Quick-drying capabilities

- Shape retention

- Eco-friendly compositions (e.g., recycled plastics)

Many china swimwear manufacturers have invested in research and development to create proprietary blends that give their products a competitive edge. For instance, some have developed fabrics that incorporate aloe vera for skin-soothing properties or bamboo fibers for enhanced breathability.

The Manufacturing Process: Precision at Scale

Once the design is finalized and materials are selected, the production process begins in earnest. China's swimwear manufacturers have honed their production techniques to achieve remarkable efficiency without compromising on quality. The typical manufacturing process includes:

1. Cutting: Precision-cutting machines slice through layers of fabric according to the digital patterns.

2. Sewing: Skilled workers assemble the pieces using specialized machines designed for stretchy fabrics.

3. Embellishment: Adding decorative elements such as beads, sequins, or embroidery.

4. Quality Control: Rigorous inspections at various stages to ensure each piece meets strict standards.

5. Finishing: Final touches such as attaching labels and packaging the products.

China's swimwear manufacturers often employ lean manufacturing principles to optimize their production lines. This approach minimizes waste, reduces lead times, and allows for greater flexibility in meeting changing market demands.

Customization and Small Batch Production

While china swimwear manufacturers are known for their ability to produce large volumes, many have also adapted to the growing demand for customization and small batch production. This flexibility allows emerging brands and independent designers to bring their visions to life without the need for massive order quantities.

Some manufacturers offer services such as:

- Low minimum order quantities (MOQs), sometimes as low as 50 pieces per style

- Custom labeling and packaging

- Personalized design consultations

- Sampling services for product testing

This adaptability has opened up new opportunities for niche markets and boutique brands, fostering innovation in the swimwear industry.

Sustainability: A Growing Priority

As environmental concerns become increasingly important to consumers, china swimwear manufacturers are adapting their practices to meet the demand for sustainable products. Many are now offering:

- Swimwear made from recycled ocean plastics

- Water-saving dyeing and printing processes

- Eco-friendly packaging options

- Certifications such as Global Recycled Standard (GRS)

These initiatives not only appeal to environmentally conscious consumers but also help brands meet their corporate social responsibility goals.

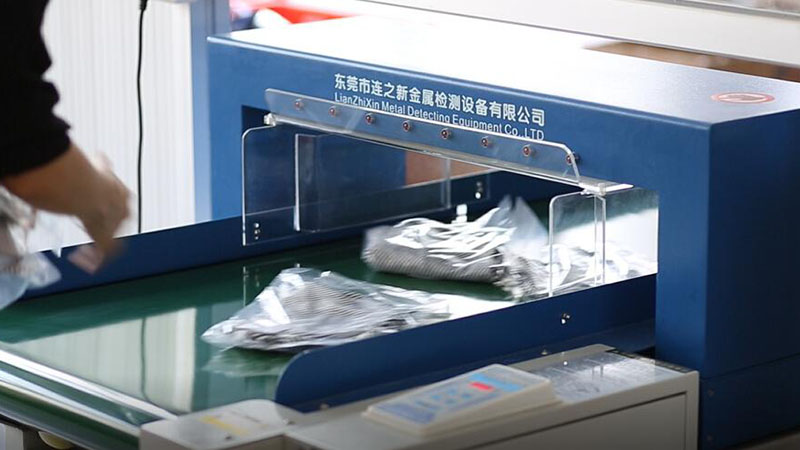

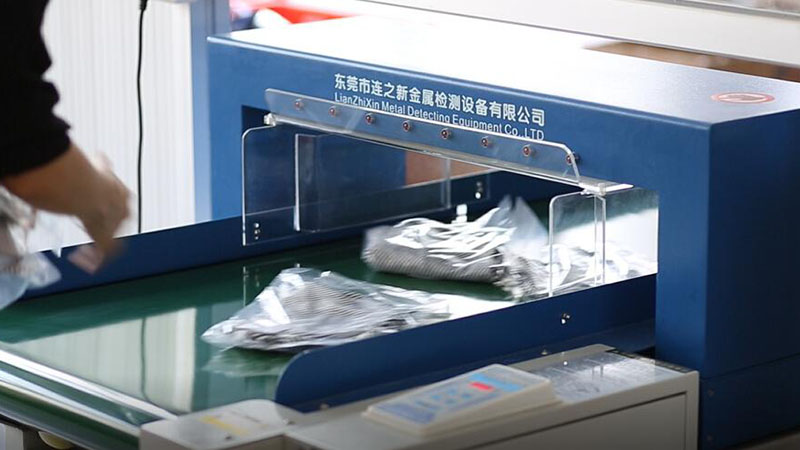

Quality Control and Compliance

Maintaining high quality standards is crucial in the competitive swimwear market. China's swimwear manufacturers have implemented rigorous quality control measures to ensure that every piece leaving their factories meets international standards. This often includes:

- Multiple inspection points throughout the production process

- Testing for colorfastness, chlorine resistance, and UV protection

- Stretch and recovery tests to ensure longevity

- Compliance with international safety standards and regulations

Many manufacturers also undergo regular audits and certifications, such as BSCI (Business Social Compliance Initiative) and GMP (Good Manufacturing Practice), to demonstrate their commitment to ethical and quality production.

The Export Process: From Factory to Global Markets

The final stage in bringing a swimwear concept to life is getting it into the hands of consumers worldwide. China's swimwear manufacturers have developed sophisticated logistics networks to ensure efficient delivery to global markets. This includes:

- Partnerships with international shipping companies

- Streamlined customs processes

- Inventory management systems for just-in-time delivery

- E-commerce integration for direct-to-consumer brands

The efficiency of this export process is one of the key reasons why china swimwear manufacturers remain competitive on the global stage.

Video: China's 'Swimwear Capital' Meets Rising Overseas Demand

Challenges and Future Outlook

Despite their dominance, china swimwear manufacturers face challenges such as rising labor costs, increasing competition from other manufacturing hubs, and the need to continually innovate. However, many are meeting these challenges head-on by:

- Investing in automation and advanced manufacturing technologies

- Focusing on higher-value, design-driven products

- Expanding their service offerings to include design, marketing, and e-commerce support

- Embracing sustainability as a core business strategy

The future of China's swimwear manufacturing industry looks bright, with continued innovation in materials, production techniques, and sustainability practices likely to keep them at the forefront of the global market.

Conclusion

From the initial spark of creativity to the final product gracing beaches around the world, china swimwear manufacturers play a crucial role in bringing swimwear concepts to life. Their combination of design expertise, manufacturing prowess, and logistical efficiency has established China as the go-to destination for swimwear production. As the industry continues to evolve, these manufacturers are poised to lead the way in innovation, sustainability, and quality, ensuring that the next great swimwear design is always just around the corner.

Frequently Asked Questions

1. Q: What makes China a leading country in swimwear manufacturing?

A: China's dominance in swimwear manufacturing is due to several factors, including skilled labor, advanced technology, a robust supply chain, competitive pricing, and the ability to produce high-quality products efficiently. The concentration of expertise in specific regions, such as Xingcheng, also contributes to China's leadership in this industry.

2. Q: How do China's swimwear manufacturers incorporate sustainability into their processes?

A: Many china swimwear manufacturers are adopting sustainable practices by using recycled materials (such as ocean plastics), implementing water-saving dyeing and printing processes, offering eco-friendly packaging options, and obtaining certifications like the Global Recycled Standard (GRS). They are also focusing on reducing waste and energy consumption in their production processes.

3. Q: What services do China's swimwear manufacturers typically offer beyond production?

A: In addition to production, many china swimwear manufacturers offer comprehensive services including design assistance, material sourcing, 3D modeling and virtual sampling, customization options, quality control, compliance certification, and logistics support for global distribution. Some also provide marketing and e-commerce integration services.

4. Q: How do China's swimwear manufacturers ensure quality control?

A: Quality control measures include multiple inspection points throughout the production process, testing for colorfastness, chlorine resistance, and UV protection, conducting stretch and recovery tests, and ensuring compliance with international safety standards. Many manufacturers also undergo regular audits and certifications such as BSCI and GMP.

5. Q: Can small brands or independent designers work with China's swimwear manufacturers?

A: Yes, many china swimwear manufacturers have adapted to offer services for small brands and independent designers. This includes offering low minimum order quantities (sometimes as low as 50 pieces per style), custom labeling and packaging, personalized design consultations, and sampling services. This flexibility allows smaller entities to bring their visions to life without requiring large production volumes.