Content Menu

● Steps to Start Your Private Label Swimwear Brand

>> Defining Your Brand and Product Requirements

>> Researching Potential Manufacturers

>> Evaluating Manufacturers: Key Factors to Consider

>> Requesting and Evaluating Samples

>> Negotiating Terms and Placing Your First Order

>> Building a Long-term Relationship

● Introduction to Private Label Swimwear

>> What is Private Label Swimwear?

>> Benefits of Private Label Swimwear

>> Why Choose Private Label Swimwear?

● The Swimwear Production Process

>> Designing the Swimwear

>> Choosing Materials

>> Manufacturing Process

>> Quality Control

● Luxury and Beachwear Suppliers

>> Luxury Swimwear

>> Beachwear Suppliers

● Conclusion

● Frequently Asked Questions (FAQs)

>> What is the difference between private label and custom swimwear?

>> How long does the swimwear production process take?

>> Can I order a small batch of swimwear?

>> What are some tips for designing my own swimwear?

Discover the best-kept secrets of the top private label swimwear manufacturers - who are they and how can you connect?

In the ever-evolving world of fashion, swimwear has become a lucrative and dynamic market. For entrepreneurs and fashion brands looking to make a splash in this industry, choosing the right private label swimwear manufacturer is a crucial step towards success. The swimwear industry is competitive, and the quality of your products can significantly impact your brand's reputation and success. This comprehensive guide will walk you through the process of selecting the perfect partner for your swimwear brand, ensuring quality, style, and profitability.

Steps to Start Your Private Label Swimwear Brand

Defining Your Brand and Product Requirements

Before you start searching for manufacturers, it's crucial to have a clear vision of your brand and product requirements. This clarity will help you communicate effectively with potential partners and ensure that they can meet your needs.

Consider the following aspects:

a) Target market: Determine who your ideal customers are, their preferences, and price points.

b) Brand aesthetic: Define your brand's style, whether it's minimalist, bohemian, athletic, or luxury.

c) Product range: Decide on the types of swimwear you want to offer (e.g., bikinis, one-pieces, tankinis) and any additional products like cover-ups or accessories.

d) Materials: Research eco-friendly fabrics or specific performance materials that align with your brand values.

e) Production volume: Estimate your initial order quantities and potential scaling needs.

f) Budget: Determine your budget for manufacturing, keeping in mind that higher quality often comes at a higher price point.

Researching Potential Manufacturers

With your brand vision and requirements in place, it's time to start researching potential private label swimwear manufacturers. Here are some effective ways to find reputable partners:

a) Search engines: Use search engines like Google and Bing to find private label manufacturers

b) Online directories: Utilize B2B platforms like Alibaba, GlobalSources, or industry-specific directories to find swimwear manufacturers.

c) Trade shows: Attend fashion and textile trade shows to meet manufacturers in person and see their products firsthand.

d) Industry networks: Join swimwear and fashion industry groups on social media platforms or forums to get recommendations from peers.

e) Local textile associations: Contact textile associations in major manufacturing hubs for referrals to reputable swimwear producers.

f) Fashion incubators: Reach out to fashion incubators or accelerators for guidance and potential manufacturer connections.

Evaluating Manufacturers: Key Factors to Consider

As you compile a list of potential manufacturers, it's important to evaluate them based on several key factors:

a) Experience and expertise: Look for manufacturers with a proven track record in swimwear production. Companies like Abely Fashion, which has been designing and manufacturing custom private label swimwear since 2003, offer valuable experience in the field.

b) Production capabilities: Assess their capacity to handle your desired order volumes and potential growth. Some manufacturers, like Fashion Bikini in Brazil, offer low minimum order quantities (MOQs) of 250 pieces, which can be beneficial for startups or small brands.

c) Quality control processes: Inquire about their quality assurance measures, including fabric testing, fit checks, and final inspections.

d) Design and customization options: Evaluate the range of styles they offer and their ability to accommodate your customization needs. For example, Appareify provides a wide variety of women's swimwear styles that can be customized for private label collections.

e) Sustainability practices: If eco-friendliness is important to your brand, look for manufacturers that use sustainable materials and ethical production methods.

f) Communication and support: Assess their responsiveness, English proficiency (if they're overseas), and willingness to provide support throughout the process.

g) Pricing and payment terms: Compare pricing structures and payment terms among different manufacturers to ensure they align with your budget and cash flow.

h) Sampling process: Understand their sampling procedures, costs, and timelines to ensure they can meet your product development needs.

i) Production lead times: Evaluate their typical production timelines to ensure they can meet your launch and restocking schedules.

j) Certifications and compliance: Check for relevant industry certifications and their compliance with international labor and safety standards.

Requesting and Evaluating Samples

Once you've shortlisted potential manufacturers, the next crucial step is to request samples. This process allows you to assess the quality of their work firsthand and determine if they can meet your expectations. Here's how to approach the sampling process:

a) Request samples of existing styles: Ask for samples of their current swimwear designs that are similar to what you're looking for. This will give you an idea of their overall quality and craftsmanship.

b) Order custom samples: If possible, request a custom sample that incorporates your specific design elements or modifications. This will help you gauge their ability to execute your vision.

c) Evaluate fabric quality: Pay close attention to the fabric's feel, stretch, and recovery. For swimwear, these factors are crucial for both comfort and durability.

d) Check construction details: Examine the stitching, seams, and finishes. Look for even, sturdy stitching and well-finished edges that won't fray or irritate the skin.

e) Test for colorfastness: Swimwear needs to withstand exposure to chlorine, saltwater, and sun. Test the samples for colorfastness by exposing them to these elements.

f) Assess fit and sizing: If possible, have the samples fitted on a model or fit form to evaluate the accuracy of sizing and overall fit.

g) Compare with competitors: Benchmark the samples against similar products from established brands to ensure your swimwear meets or exceeds market standards.

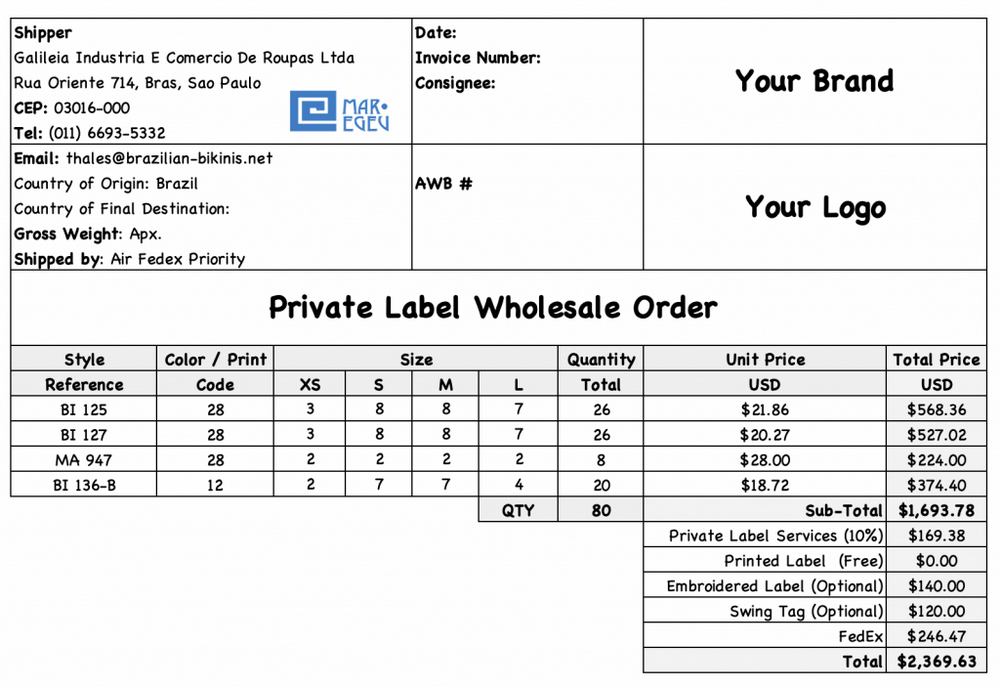

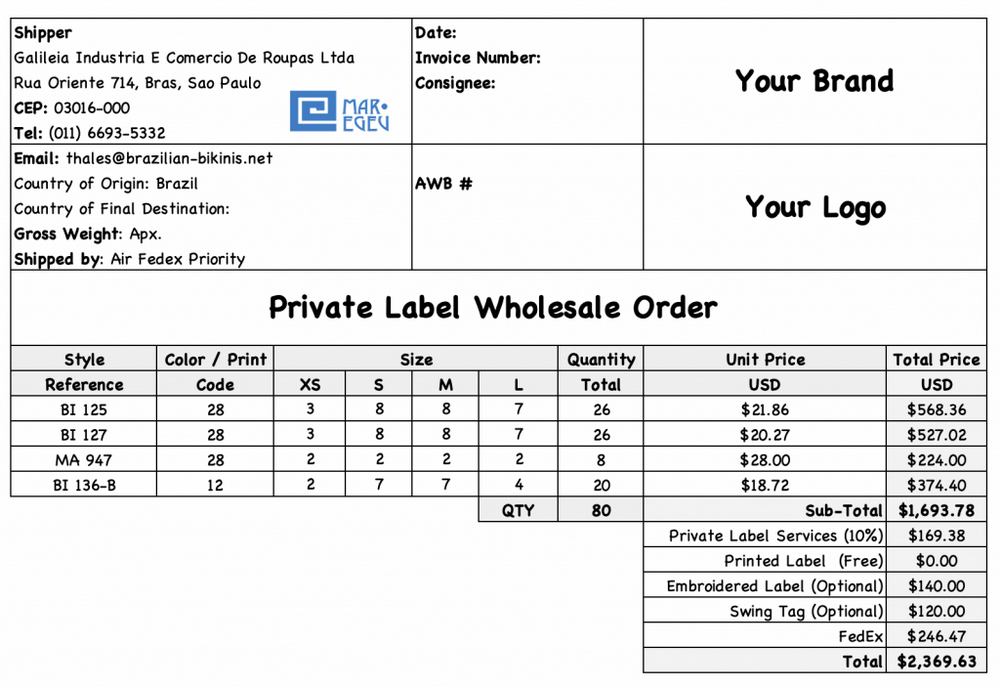

Negotiating Terms and Placing Your First Order

After evaluating samples and selecting your preferred manufacturer, it's time to negotiate terms and place your first order. Here are some key points to consider during this phase:

a) Minimum Order Quantities (MOQs): Negotiate MOQs that align with your initial production needs and budget. Some manufacturers may be willing to start with lower quantities for new clients.

b) Pricing structure: Discuss pricing for different order volumes and any potential discounts for larger orders or long-term partnerships.

c) Payment terms: Agree on payment schedules and methods. Common terms include a deposit upfront with the balance due before shipping or upon delivery.

d) Production timeline: Establish clear deadlines for each stage of production, including design approval, sampling, bulk production, and shipping.

e) Quality control measures: Outline the quality control processes that will be implemented throughout production, including any third-party inspections.

f) Intellectual property protection: Ensure that your designs and brand elements are protected through non-disclosure agreements (NDAs) and clear contract terms.

g) Shipping and logistics: Discuss shipping options, costs, and responsibilities. Determine whether the manufacturer will handle export procedures or if you need to arrange for this separately.

h) Warranty and returns policy: Clarify the manufacturer's policy on defective products and how they handle returns or replacements.

i) Future order projections: Discuss your growth plans and how the manufacturer can scale production to meet your future needs.

Building a Long-term Relationship

Choosing a private label swimwear manufacturer is not just about the initial order; it's about building a long-term partnership that can support your brand's growth. Here are some tips for nurturing this relationship:

a) Maintain open communication: Keep your manufacturer informed about your sales performance, customer feedback, and future plans. This helps them better anticipate your needs and suggest improvements.

b) Visit the factory: If possible, schedule visits to the manufacturing facility to strengthen your relationship and gain a better understanding of their operations.

c) Provide feedback: Offer constructive feedback on samples and production runs to help the manufacturer improve and better meet your needs.

d) Stay informed about innovations: Keep up with advancements in swimwear fabrics and manufacturing techniques, and discuss implementing these innovations with your manufacturer.

e) Plan ahead: Give your manufacturer ample notice for large orders or new product launches to ensure they can accommodate your needs.

f) Be loyal but vigilant: While building a strong relationship with your manufacturer is important, always keep an eye on the market to ensure you're getting the best value and quality.

Introduction to Private Label Swimwear

Private label swimwear is an exciting part of the fashion world. It lets businesses create and sell swimwear without making it themselves. Instead, they work with other companies, known as custom swimwear manufacturers, to produce the items. This means the swimwear has the business's own brand name on it, making it unique to them.

What is Private Label Swimwear?

Private label swimwear refers to swimwear that is made by one company but is sold under a different brand name. This allows businesses to offer their own styles and designs without having to invest in the whole production process. They can focus on marketing and selling their brand while relying on skilled manufacturers to create the actual products.

Benefits of Private Label Swimwear

◆ Cost-Effective: Private labeling can be more affordable than custom manufacturing, as you can leverage existing designs and production processes.

◆ Brand Control: You have the opportunity to create a unique brand identity while relying on the expertise of established manufacturers.

◆ Faster Time to Market: With pre-existing designs, you can launch your products more quickly than if you were to create everything from scratch.

Why Choose Private Label Swimwear?

Choosing private label swimwear has many benefits. First, it helps create a unique brand identity. This means customers can recognize the brand and what it stands for. Second, it allows businesses to offer swimwear that is different from others in the market. Many businesses like this option because they can provide special styles or features that make their swimwear stand out. Overall, private label swimwear helps brands grow and connect with their customers in a special way.

The Swimwear Production Process

The swimwear production process is a series of important steps that help turn ideas into beautiful swimwear you see in stores. It involves creativity, careful choices, and skilled work. Let's explore how custom swimwear manufacturers take a design from concept to finished product.

Designing the Swimwear

The first step in the swimwear production process is designing the swimwear. Designers think of new styles and colors that will look great on the beach. They look at the latest trends, too, to make sure the swimwear is fashionable. Creativity is key! Designers sketch their ideas and choose patterns that will catch people's eyes. It's a fun stage that sets the tone for everything that follows.

Choosing Materials

Next comes choosing the materials. Custom swimwear manufacturers decide what fabrics to use, and this is really important. Popular choices are Lycra and spandex because they are stretchy and comfortable. The right material helps the swimwear fit well and last longer. If the fabric is not good, the swimwear might not be fun to wear. So, picking the best materials is a big part of the swimwear production process.

Manufacturing Process

Once the designs and materials are ready, it's time for the manufacturing process. This is where the magic happens! The fabric is cut into the right shapes, and then skilled workers sew the pieces together. They also add any special features like pockets or fun designs. This step requires a lot of care and attention to detail to make sure the swimwear looks perfect and fits well.

Quality Control

Finally, after the swimwear is made, it goes through quality control. This means that the manufacturers check each piece of swimwear to make sure it is high quality before it gets shipped out. They look for things like loose threads or any mistakes. This step is super important because no one wants to wear swimwear that isn’t made well. Quality control helps ensure that customers are happy with their swimwear when they buy it.

Luxury and Beachwear Suppliers

When it comes to swimwear, not all brands are the same. Some focus on luxury and special beachwear that makes people feel amazing. Understanding the options available from luxury swimwear manufacturers and beachwear suppliers can help businesses choose the right paths for their brands.

Luxury Swimwear

Luxury swimwear is like the fancy dessert of the swimwear world! It’s made from the best materials and often has unique designs. What makes luxury swimwear special is not just how it looks but also how it feels. These swimsuits are created with extra care and detail, which is why they usually cost more. They often feel softer on the skin, fit better, and last longer than regular swimwear. Many luxury swimwear manufacturers are known for their stylish and high-quality products, making them a top choice for those wanting to stand out at the beach or pool.

Beachwear Suppliers

Beachwear suppliers offer a variety of products that people might need when they head to the beach. This includes items like cover-ups, hats, and beach bags. Suppliers that focus on beachwear understand what customers look for when they want to enjoy a sunny day by the water. They often have fun colors and patterns that make beach trips more exciting. Having a good relationship with beachwear suppliers can help businesses get the coolest accessories that match their swimwear lines, appealing to customers looking for a complete beach look.

Conclusion

Choosing the right private label swimwear manufacturer is a critical decision that can significantly impact your brand's success. By thoroughly researching potential partners, carefully evaluating samples, negotiating favorable terms, and building a strong, long-term relationship, you can create a successful swimwear line that stands out in the competitive fashion market.

Remember that this process requires time, patience, and attention to detail. Don't rush into a partnership without doing your due diligence. The right manufacturer will not only produce high-quality swimwear but will also serve as a valuable partner in your brand's growth and evolution.

As you embark on this journey, keep in mind that the swimwear industry is constantly evolving. Stay informed about trends, consumer preferences, and technological advancements in fabric and manufacturing. This knowledge will help you make informed decisions and keep your brand at the forefront of the swimwear market.

Ultimately, the success of your private label swimwear brand depends on the perfect blend of your unique vision and the expertise of your chosen manufacturer. With the right partner by your side, you'll be well-equipped to make waves in the exciting world of swimwear fashion.

Frequently Asked Questions (FAQs)

What is the difference between private label and custom swimwear?

Private label swimwear is when a business sells swimwear made by another company but with its own brand name. This means the manufacturer does all the making, and the business just puts its label on it. On the other hand, custom swimwear means the business is involved in the design and production process. They might work closely with custom swimwear manufacturers to create unique styles that fit their vision. If you want something simple and ready to sell, private label is a good choice. If you want more control over the design, custom swimwear might be better.

How long does the swimwear production process take?

The swimwear production process can take anywhere from a few weeks to a couple of months. It depends on many things like the design, materials, and how busy the custom swimwear manufacturers are. After the designs are approved, it usually takes about 4 to 8 weeks for the swimwear to be made and ready to ship. So, if you're planning to launch your swimwear brand, it's smart to start early!

Can I order a small batch of swimwear?

Yes, many manufacturers understand that new businesses might not need a lot of swimwear at first. Some custom swimwear manufacturers offer options for ordering smaller quantities. This means you can test your designs without having to buy a ton of swimwear at once. Just make sure to ask the manufacturer if they have a minimum order requirement.

What are some tips for designing my own swimwear?

When designing your own swimwear, keep these tips in mind: first, think about your target audience. Know what styles and colors they like. Second, focus on comfort! Choose materials that feel nice against the skin, like Lycra or spandex. Third, pay attention to trends! Check out current swimwear styles and see what’s popular. Finally, don’t forget about the details. Add fun elements like unique patterns or cool straps to make your swimwear stand out.