Content Menu

● Understanding OEM Swimwear

● The OEM Swimwear Manufacturing Process

>> Design and Conceptualization

>> Pattern Making and Prototyping

>> Material Selection

>> Sample Production

>> Bulk Production

>> Finishing and Packaging

● Benefits of OEM Swimwear Manufacturing

● Trends in OEM Swimwear

● Key Considerations for OEM Swimwear Manufacturing

● The Future of OEM Swimwear

● Custom Swimwear

>> What is Custom Swimwear?

>> Why Choose Custom Swimwear?

● Designing Swimwear

>> The Design Process

>> Inspiration for Designs

● Conclusion

In the ever-evolving world of fashion, swimwear holds a unique and vibrant position. As beaches and poolsides become increasingly popular destinations for leisure and social gatherings, the demand for stylish, comfortable, and high-quality swimwear continues to grow. This surge in demand has led to a significant rise in the OEM (Original Equipment Manufacturer) swimwear industry. OEM swimwear manufacturing offers brands and designers the opportunity to create unique, branded swimwear without the need for in-house production facilities. This comprehensive guide will delve into the intricacies of OEM swimwear, exploring the manufacturing process, benefits, trends, and key considerations for those looking to enter or expand in this exciting market.

Understanding OEM Swimwear

OEM swimwear refers to swimwear products that are designed by one company but manufactured by another. This model allows brands to focus on design, marketing, and sales while leveraging the expertise and resources of specialized manufacturers. The OEM swimwear process typically involves a brand providing designs, specifications, and requirements to a manufacturer, who then produces the swimwear according to these specifications under the brand's label.

The OEM swimwear model has gained popularity due to its flexibility and cost-effectiveness. It allows smaller brands and startups to enter the market without significant upfront investment in manufacturing infrastructure. Additionally, established brands can use OEM partnerships to expand their product lines or test new designs without committing to large-scale production.

The OEM Swimwear Manufacturing Process

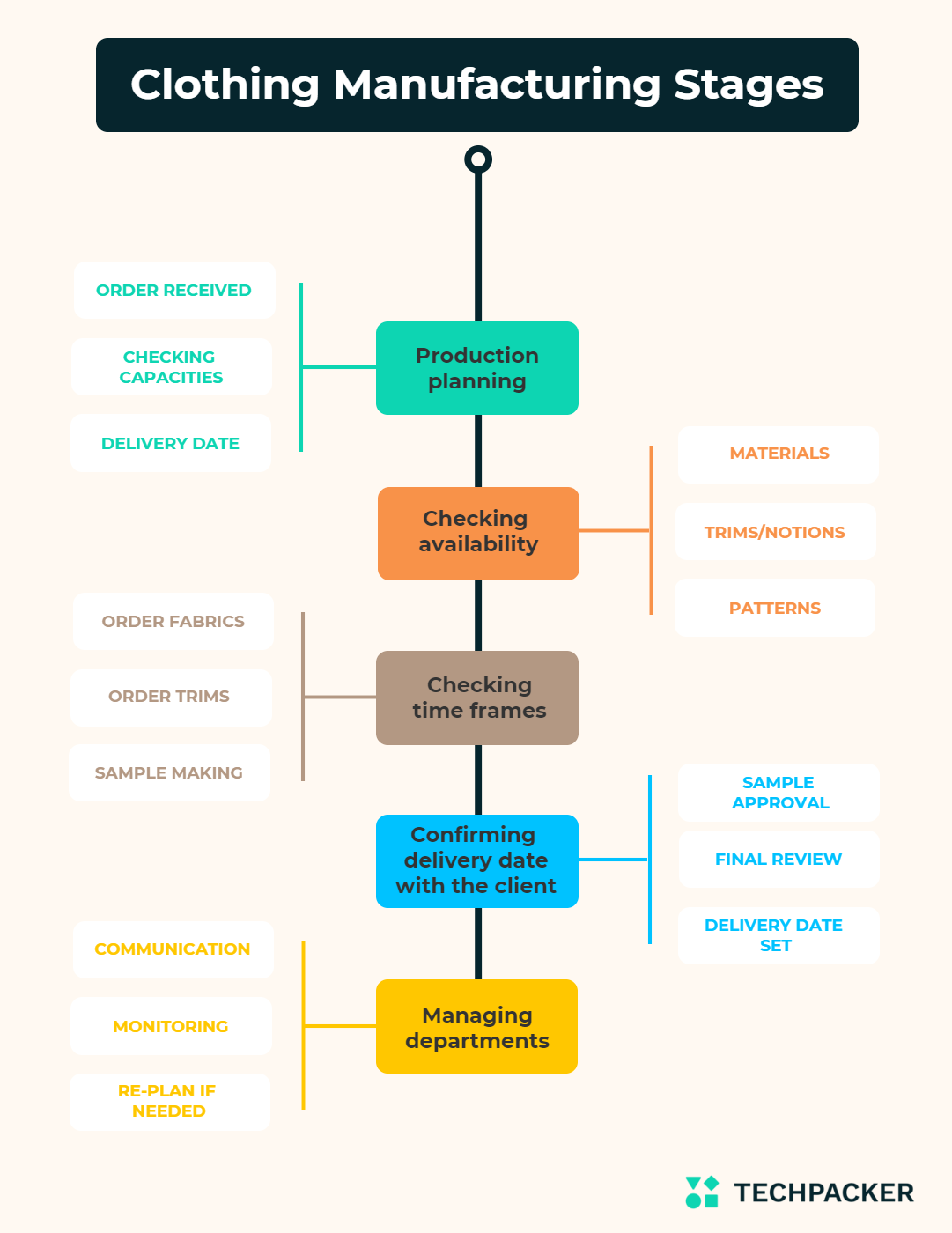

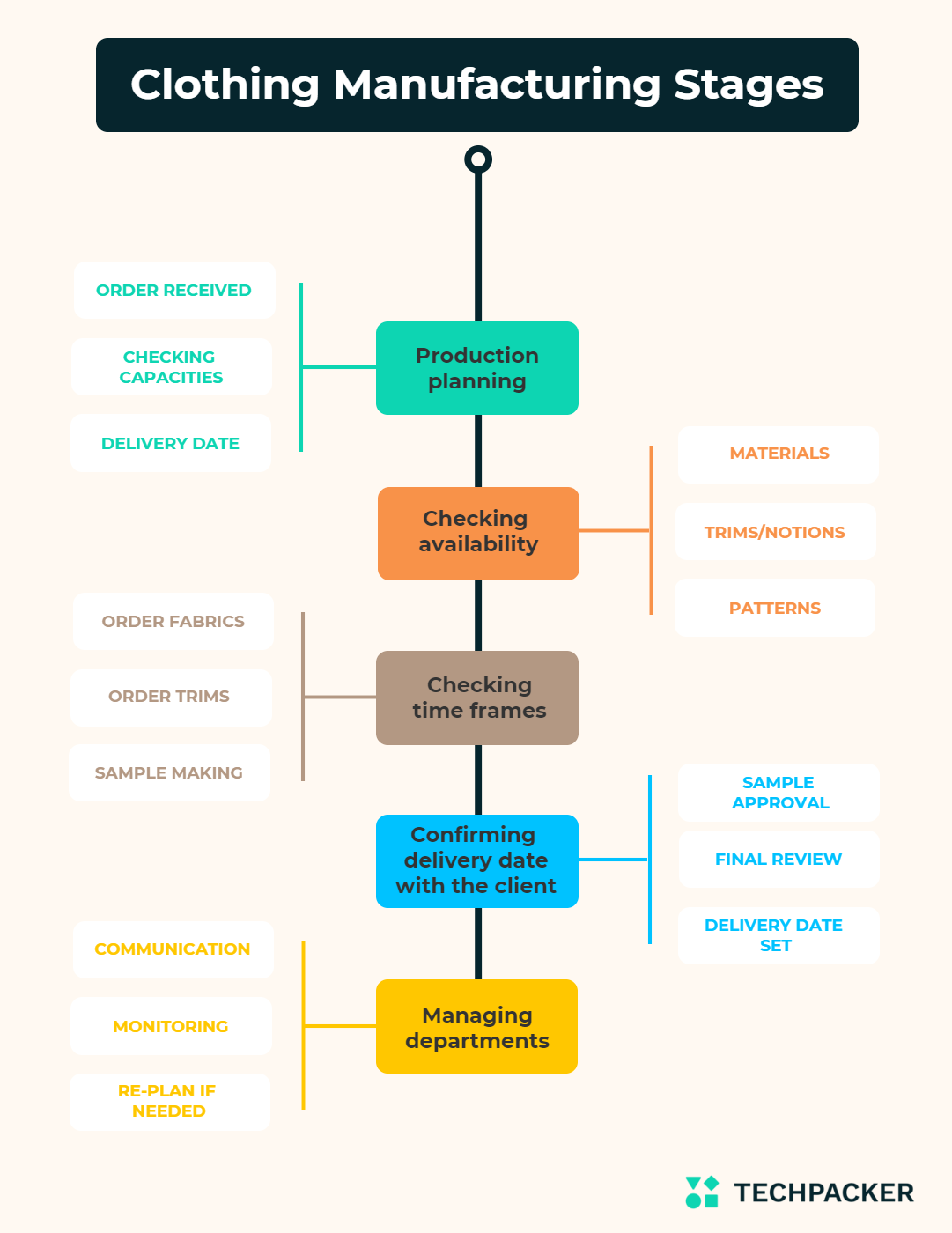

The journey from concept to creation in OEM swimwear manufacturing is a complex and multifaceted process that requires attention to detail, creativity, and technical precision. Let's break down the key stages of this process:

Design and Conceptualization

The process begins with the brand's design team creating concepts for new swimwear collections. This stage involves researching current fashion trends, analyzing consumer preferences, and considering technological innovations in fabric and construction techniques. Designers create sketches, select color palettes, and determine the overall aesthetic of the collection.

Pattern Making and Prototyping

Once the designs are finalized, pattern makers translate the sketches into technical patterns. These patterns are crucial as they determine the fit, shape, and construction of the swimwear. Prototypes are then created using these patterns, allowing designers to assess the fit, comfort, and overall look of the garment. Multiple iterations may be necessary to achieve the perfect design.

Material Selection

Choosing the right materials is critical in OEM swimwear manufacturing. Factors such as durability, stretch, color fastness, and resistance to chlorine and saltwater must be considered. Many OEM swimwear manufacturers are now focusing on sustainable materials, such as recycled polyester or nylon, to meet growing consumer demand for eco-friendly products.

Sample Production

After finalizing the design and selecting materials, the OEM manufacturer produces a small batch of samples. These samples allow the brand to evaluate the quality, fit, and overall appearance of the swimwear before committing to full production. It's also an opportunity to make any final adjustments to the design or construction.

Bulk Production

Once the samples are approved, the OEM swimwear manufacturer begins bulk production. This stage involves cutting the fabric according to the patterns, sewing the pieces together, adding any embellishments or prints, and attaching labels and tags. Quality control checks are performed throughout the production process to ensure consistency and adherence to specifications.

Finishing and Packaging

After production, the swimwear undergoes final quality checks and finishing processes. This may include trimming excess threads, steaming or pressing the garments, and adding any final touches. The swimwear is then packaged according to the brand's specifications, ready for distribution.

Benefits of OEM Swimwear Manufacturing

OEM swimwear manufacturing offers numerous advantages for brands of all sizes:

1. Cost-Effectiveness: By outsourcing production to specialized manufacturers, brands can avoid the significant capital investment required for setting up and maintaining production facilities. This allows for more competitive pricing and higher profit margins.

2. Access to Expertise: OEM swimwear manufacturers often have years of experience and specialized knowledge in swimwear production. This expertise can lead to higher quality products and innovative solutions to design challenges.

3. Flexibility and Scalability: OEM partnerships allow brands to easily scale production up or down based on demand, without the constraints of in-house manufacturing capacity.

4. Focus on Core Competencies: By outsourcing production, brands can focus their resources and energy on design, marketing, and sales – areas that directly impact brand growth and consumer engagement.

5. Quick Time-to-Market: Established OEM swimwear manufacturers often have streamlined processes that can significantly reduce the time from design to market, allowing brands to respond quickly to emerging trends.

6. Access to Advanced Technology: Many OEM manufacturers invest in the latest production technologies, which may be too costly for individual brands to acquire. This access to advanced technology can result in higher quality products and more efficient production processes.

Trends in OEM Swimwear

The OEM swimwear industry is constantly evolving, driven by changing consumer preferences, technological advancements, and broader fashion trends. Some current trends in OEM swimwear include:

1. Sustainability: There's a growing demand for eco-friendly swimwear made from recycled materials or sustainable fabrics. Many OEM manufacturers are adapting their processes to accommodate this trend, using materials like ECONYL (recycled nylon) or REPREVE (recycled polyester).

2. Inclusivity: Brands are increasingly focusing on inclusive sizing and designs that cater to a diverse range of body types. This trend is influencing the design and production processes in OEM swimwear manufacturing.

3. Multifunctionality: Swimwear that can transition from beach to street wear is gaining popularity. This trend requires OEM manufacturers to work with more versatile fabrics and innovative designs.

4. Technology Integration: Some OEM swimwear manufacturers are exploring ways to integrate technology into swimwear, such as UV protection indicators or moisture-wicking properties.

5. Customization: There's a growing trend towards personalized swimwear. Some OEM manufacturers are developing processes to allow for greater customization, such as digital printing for unique patterns or on-demand production.

Key Considerations for OEM Swimwear Manufacturing

For brands considering OEM swimwear manufacturing, there are several important factors to consider:

1. Quality Control: Ensuring consistent quality across production runs is crucial. It's important to work with OEM manufacturers who have robust quality control processes in place.

2. Compliance and Certifications: Depending on the target market, swimwear may need to meet certain safety standards or certifications. Brands should ensure their OEM partners are compliant with relevant regulations.

3. Minimum Order Quantities (MOQs): OEM manufacturers often have minimum order quantities. Brands should consider their inventory needs and cash flow when negotiating MOQs.

4. Lead Times: Understanding the manufacturer's lead times is crucial for inventory planning and meeting seasonal demands.

5. Communication: Clear and frequent communication with the OEM manufacturer is essential to ensure that designs are accurately translated into finished products.

6. Intellectual Property Protection: Brands should have clear agreements in place to protect their designs and prevent unauthorized reproduction.

7. Sustainability Practices: As consumers become more environmentally conscious, brands should consider the sustainability practices of their OEM partners.

The Future of OEM Swimwear

The OEM swimwear industry is poised for continued growth and innovation. As technology advances, we can expect to see more sustainable production methods, increased customization options, and potentially even smart swimwear that integrates wearable technology.

3D printing technology may also play a larger role in OEM swimwear manufacturing in the future, potentially allowing for more complex designs and personalized fits. Additionally, as e-commerce continues to grow, we may see more OEM manufacturers offering direct-to-consumer options, further blurring the lines between manufacturing and retail.

Custom Swimwear

Custom swimwear is a special type of swimwear made just for you! It means you can pick the colors, patterns, and styles that you love. Custom swimwear is different from regular swimwear because it fits your body perfectly and matches your unique taste.

What is Custom Swimwear?

When we talk about custom swimwear, we mean swimwear that is designed specifically for an individual. This means you can have a one-piece suit or a bikini that is made to fit your measurements. Unlike off-the-rack swimwear that you find in stores, custom swimwear is created to make sure it looks great on you. The designers take your size and preferences into account, so you get something that feels comfortable and stylish.

Why Choose Custom Swimwear?

There are many reasons why someone might want custom swimwear. First, the fit is usually much better than regular swimwear. When something fits well, it feels good to wear! You don't have to worry about it being too tight or too loose while you swim or play at the beach.

Another reason to choose custom swimwear is the opportunity for unique designs. You can create a look that no one else has! This is a great way to express yourself and show off your personality. Whether you want bright colors, fun patterns, or even your favorite cartoon characters, custom swimwear lets you stand out from the crowd.

In addition, custom swimwear can also be made from special materials that look good and help you swim better. This means you can enjoy your time in the water while looking fashionable at the same time. With all these benefits, it's easy to see why so many people are excited about custom swimwear!

Designing Swimwear

Designing swimwear is an exciting process that combines creativity and function. It is all about making swimwear designs that look great and feel comfortable. Whether it's a fun bikini or a stylish one-piece, each piece of custom swimwear has a special purpose. Let's dive into how swimwear is designed and what makes it unique!

The Design Process

The design process for swimwear starts with an idea. Designers often draw sketches to show how they want the swimwear to look. These sketches include details like the shape, style, and colors of the swimsuit. Once the sketches are ready, the next step is to choose the right fabrics. Swimwear needs to be made from special materials that can handle water and drying quickly. Designers look for fabrics that are stretchy, soft, and durable. This helps the swimwear fit well and last longer, making it perfect for swimming and beach fun!

Inspiration for Designs

Designers get their inspiration from many places. Nature is a big source of ideas, with beautiful colors and patterns found in flowers, fish, and even the ocean itself. Art and culture also play an important role. For example, a designer might use patterns inspired by famous paintings or traditional clothing from different countries. By mixing these inspirations, designers create unique swimwear that stands out. This is how fashion swimwear becomes a way to express personal style while enjoying the water!

Conclusion

OEM swimwear manufacturing offers a flexible, cost-effective solution for brands looking to enter or expand in the swimwear market. By understanding the manufacturing process, staying abreast of current trends, and carefully considering key factors, brands can leverage OEM partnerships to create high-quality, innovative swimwear that meets the evolving demands of consumers.

As the industry continues to evolve, the relationship between brands and OEM swimwear manufacturers will likely become even more collaborative and integrated. This partnership will drive innovation, sustainability, and growth in the exciting world of swimwear fashion.

Whether you're a startup looking to launch your first swimwear line or an established brand seeking to expand your offerings, OEM swimwear manufacturing provides a pathway to bring your vision to life. By harnessing the expertise, resources, and flexibility of OEM partners, brands can navigate the complexities of swimwear production and focus on what they do best – creating beautiful, functional designs that resonate with their target audience.