Content Menu

● The Bathing Suit Factory: A Hub of Creativity and Precision

● The Design Process: Where Innovation Begins

● Material Selection: The Foundation of Quality Swimwear

● Pattern Making: The Blueprint of Swimwear

● Cutting and Preparation: Precision in Action

● Sewing and Assembly: Where Skill Meets Technology

● Finishing Touches: Elevating the Final Product

● Quality Control: Ensuring Excellence

● Packaging and Distribution: The Final Journey

● Innovation and Sustainability in Bathing Suit Factories

● The Human Element in Bathing Suit Production

● The Global Impact of Bathing Suit Factories

● Conclusion: The Artistry and Science of Bathing Suit Manufacturing

In the ever-evolving landscape of fashion, few garments capture the essence of summer and leisure quite like the bathing suit. Behind every stylish swimwear piece lies a complex and fascinating world of design, innovation, and manufacturing. Today, we'll take an in-depth look at the inner workings of bathing suit factories, exploring the intricate processes that bring these essential summer staples to life.

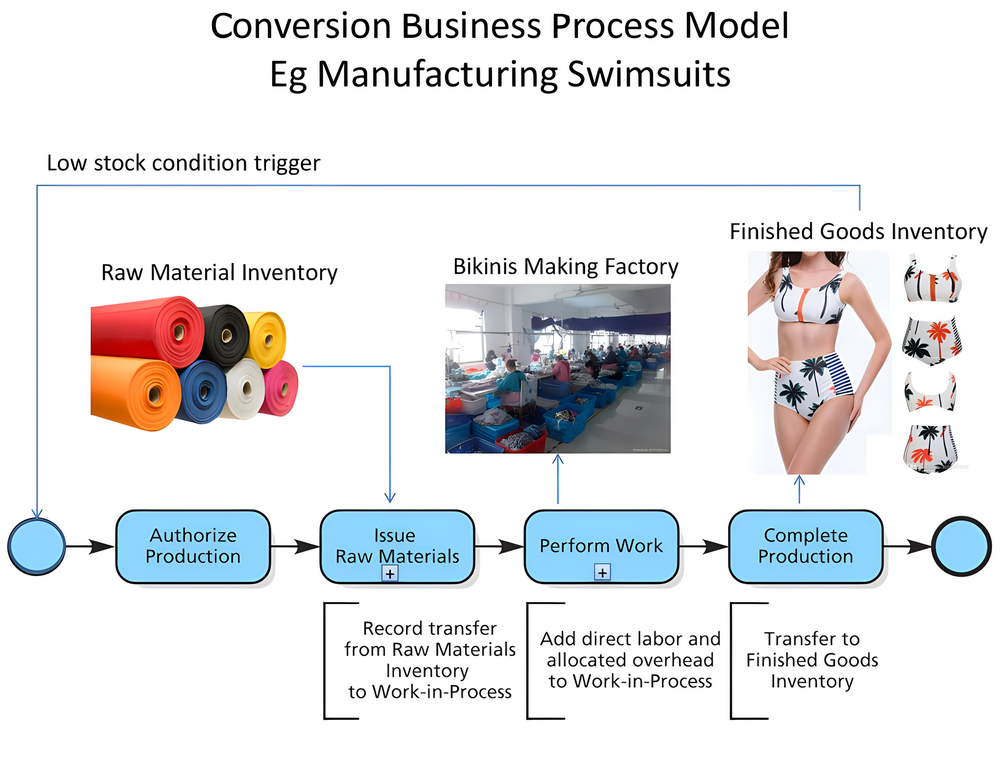

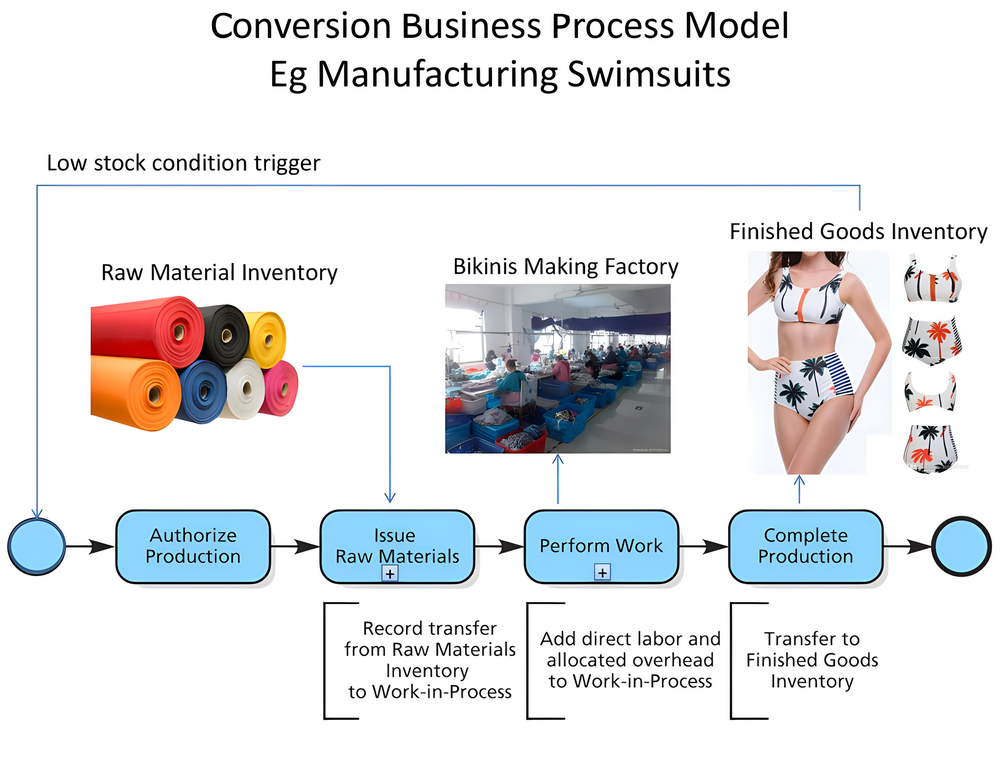

The Bathing Suit Factory: A Hub of Creativity and Precision

At first glance, a bathing suit factory might appear to be just another garment production facility. However, these specialized establishments are unique in their approach to creating swimwear that not only looks good but also performs well in water. The bathing suit factory is a place where fashion meets function, and where every stitch and seam is crucial to the final product's success.

As we step into a typical bathing suit factory, we're greeted by a bustling environment filled with the hum of sewing machines, the rustle of fabrics, and the focused energy of skilled workers. The air is thick with creativity and precision, as designers, pattern makers, and seamstresses work in harmony to bring swimwear concepts to life.

The Design Process: Where Innovation Begins

The journey of a bathing suit starts long before it reaches the production floor of a bathing suit factory. It begins in the minds of talented designers who are constantly pushing the boundaries of swimwear fashion. These creative professionals are tasked with not only keeping up with current trends but also anticipating future styles that will captivate consumers.

In the design department of a bathing suit factory, you'll find mood boards adorned with swatches of vibrant fabrics, sketches of daring new cuts, and inspiration drawn from various sources – from nature to urban landscapes. Designers in a bathing suit factory must consider a multitude of factors when creating new swimwear lines:

1. Fashion trends and consumer preferences

2. Functionality and performance in water

3. Body diversity and inclusivity

4. Sustainability and eco-friendly materials

5. Durability and longevity of the garment

The design process in a bathing suit factory is iterative, with concepts being refined and perfected through multiple rounds of sketching, digital rendering, and prototyping. It's not uncommon to see designers huddled around tables, discussing the merits of different design elements and how they can be incorporated into the final product.

Material Selection: The Foundation of Quality Swimwear

One of the most critical aspects of bathing suit production is the selection of materials. The fabrics used in swimwear must meet a unique set of requirements that few other garments demand. They need to be:

◆ Quick-drying

◆ Resistant to chlorine and saltwater

◆ Able to maintain shape and elasticity when wet

◆ Comfortable against the skin

◆ UV-resistant

◆ Durable enough to withstand frequent use

In a modern bathing suit factory, you'll find an impressive array of high-tech fabrics designed specifically for swimwear. These may include:

◆ Nylon and polyester blends

◆ Spandex and elastane for stretch

◆ Recycled materials for eco-friendly options

◆ Neoprene for thermal protection

◆ Specialty fabrics with moisture-wicking or UV-blocking properties

The material selection process in a bathing suit factory involves close collaboration between designers and fabric specialists. They work together to choose the perfect materials that will bring the design to life while meeting all the necessary performance criteria.

Pattern Making: The Blueprint of Swimwear

Once the designs are finalized and materials selected, the next crucial step in the bathing suit factory is pattern making. This is where two-dimensional designs are transformed into three-dimensional garments that will fit and flatter the human body.

Pattern makers in a bathing suit factory are highly skilled professionals who understand the intricacies of how fabric behaves when worn, especially in water. They create precise patterns that, when cut and sewn, will result in swimwear that fits perfectly and performs as intended.

The pattern-making process in a bathing suit factory often involves:

1. Creating initial paper patterns based on design specifications

2. Digitizing patterns for computer-aided design (CAD) systems

3. Grading patterns to accommodate different sizes

4. Making adjustments for various body types and shapes

5. Ensuring patterns allow for proper stretch and recovery of the fabric

In many modern bathing suit factories, you'll find a mix of traditional pattern-making techniques and cutting-edge technology. Computer software allows for precise adjustments and easy scaling of patterns, while skilled pattern makers still rely on their expertise to ensure the final product meets the high standards expected of quality swimwear.

Cutting and Preparation: Precision in Action

With patterns ready and materials at hand, the bathing suit factory moves into the cutting phase. This stage requires extreme precision, as even the slightest deviation can affect the fit and performance of the final product.

In a state-of-the-art bathing suit factory, you might see:

◆ Automated cutting machines that use computer-guided lasers or blades to cut fabric with pinpoint accuracy

◆ Skilled workers carefully aligning patterns on fabric to minimize waste

◆ Specialized cutting tools for handling delicate or stretchy materials

The cutting process in a bathing suit factory is not just about following the pattern lines. It's also about maximizing the use of fabric to reduce waste, a crucial consideration in today's environmentally conscious manufacturing landscape.

Sewing and Assembly: Where Skill Meets Technology

The heart of any bathing suit factory is undoubtedly the sewing floor. Here, the cut pieces of fabric begin to take shape as skilled seamstresses and advanced sewing machines work in tandem to create the final product.

Sewing swimwear requires specialized techniques and equipment. In a bathing suit factory, you'll find:

◆ Overlock machines for creating strong, flexible seams

◆ Coverstitch machines for adding decorative and functional stitching

◆ Heat press machines for applying appliques and embellishments

◆ Specialized needles and threads designed for use with stretchy fabrics

The assembly process in a bathing suit factory is often broken down into stages, with different stations focusing on specific parts of the garment. For example:

◆ Joining main body panels

◆ Attaching straps and closures

◆ Adding linings and support elements

◆ Sewing in labels and care instructions

◆ Applying decorative elements and finishes

Quality control is paramount at every step of the sewing process. In a well-run bathing suit factory, each piece is inspected multiple times to ensure that seams are strong, stitches are even, and the garment is taking shape as intended.

Finishing Touches: Elevating the Final Product

As the bathing suits near completion, the bathing suit factory turns its attention to the finishing touches that will elevate the garment from good to great. This may include:

◆ Adding padding or underwire for support

◆ Attaching decorative elements like beads or sequins

◆ Applying heat transfers or prints

◆ Installing adjustable components like sliders on straps

It's in these final stages that the true craftsmanship of the bathing suit factory shines through. Skilled workers meticulously check each piece, ensuring that every element is securely attached and functioning as intended.

Quality Control: Ensuring Excellence

Before any bathing suit leaves the factory, it undergoes rigorous quality control checks. In a reputable bathing suit factory, this process is thorough and uncompromising. Quality control specialists examine each garment for:

◆ Accurate sizing and fit

◆ Strength and elasticity of seams

◆ Colorfastness and resistance to fading

◆ Proper functioning of closures and adjustable elements

◆ Overall appearance and adherence to design specifications

Many bathing suit factories also conduct performance tests, subjecting sample garments to conditions that simulate real-world use. This might include exposure to chlorinated water, saltwater, and UV light to ensure the swimwear can withstand the rigors of beach and pool environments.

Packaging and Distribution: The Final Journey

Once a bathing suit has passed all quality checks, it's ready for packaging and distribution. In the packaging area of a bathing suit factory, you'll see:

◆ Workers carefully folding and arranging garments

◆ Machines applying hang tags and price labels

◆ Protective packaging being added to prevent damage during shipping

The packaging process in a bathing suit factory is designed not only to protect the garment but also to present it attractively to the end consumer. Many brands use this as an opportunity to reinforce their brand identity through custom packaging and inserts.

Innovation and Sustainability in Bathing Suit Factories

As the fashion industry evolves, so too do bathing suit factories. Many are at the forefront of innovation, incorporating new technologies and sustainable practices into their operations. Some notable trends in modern bathing suit factories include:

1. 3D printing for prototyping and small-batch production

2. Use of recycled and eco-friendly materials

3. Implementation of water-saving and energy-efficient manufacturing processes

4. Development of biodegradable swimwear fabrics

5. Integration of wearable technology into swimwear designs

These innovations are not just about staying competitive; they're about responding to consumer demand for more sustainable and technologically advanced products. Forward-thinking bathing suit factories are investing in research and development to create swimwear that not only looks good but also minimizes environmental impact.

The Human Element in Bathing Suit Production

While technology plays an increasingly important role in bathing suit factories, the human element remains crucial. From designers to seamstresses, pattern makers to quality control specialists, it's the skill and dedication of the workforce that truly brings swimwear to life.

Many bathing suit factories pride themselves on nurturing talent and preserving traditional craftsmanship alongside modern production methods. Training programs and apprenticeships ensure that the art of swimwear manufacturing is passed down to new generations of workers.

The Global Impact of Bathing Suit Factories

Bathing suit factories are not just local enterprises; they're part of a global industry that spans continents. Many brands operate or contract with factories in different parts of the world, each bringing its own unique strengths to the production process.

This global network of bathing suit factories allows for:

◆ Access to diverse skill sets and manufacturing techniques

◆ Ability to meet varying labor and production costs

◆ Proximity to different markets and faster response to regional trends

◆ Utilization of local materials and traditional craftsmanship

However, this globalization also brings challenges, particularly in ensuring consistent quality and ethical manufacturing practices across different locations. Responsible bathing suit factories and brands are increasingly focusing on transparency and fair labor practices throughout their supply chains.

Conclusion: The Artistry and Science of Bathing Suit Manufacturing

From the initial spark of design inspiration to the final quality check, the journey of a bathing suit through a factory is a testament to the blend of artistry and science that goes into creating these seemingly simple garments. Bathing suit factories are dynamic environments where creativity meets precision engineering, where traditional skills coexist with cutting-edge technology.

As consumers, we often take for granted the complexity behind the swimwear we don each summer. But behind every bikini, one-piece, or board short is a world of innovation, skill, and dedication. The next time you slip on a bathing suit, take a moment to appreciate the intricate process and the many hands that brought it from concept to reality in a bathing suit factory.

In an industry that's constantly evolving, bathing suit factories continue to push boundaries, embracing new technologies and sustainable practices while honoring the craft that has defined swimwear production for generations. As we look to the future, we can expect these factories to play a crucial role in shaping not just what we wear to the beach or pool, but also how we think about fashion, sustainability, and the intersection of form and function in our clothing.