Content Menu

● Introduction

● Understanding the OEM Swimwear Production Process

>> Initial Consultation

>> Design Development

>> Sampling Phase

>> Production Planning

>> Manufacturing Process

>> Quality Control and Assurance

>> Packaging and Shipping

>> Post-Production Support

● Conclusion

● Frequently Asked Questions

>> 1. What is OEM swimwear manufacturing?

>> 2. How long does the OEM swimwear production process take?

>> 3. What are the benefits of working with OEM swimwear manufacturers?

>> 4. Can OEM swimwear manufacturers help with design development?

>> 5. What quality control measures do OEM swimwear manufacturers implement?

Introduction

In the competitive world of fashion, particularly in the swimwear industry, Original Equipment Manufacturer (OEM) services play a crucial role. OEM swimwear manufacturers provide brands with the ability to produce high-quality swimwear without the need for extensive in-house production capabilities. This article will explore the OEM swimwear production process in detail, highlighting the steps involved, the importance of collaboration, and the benefits of working with OEM manufacturers.

Understanding the OEM Swimwear Production Process

The OEM swimwear production process is a comprehensive journey that begins with understanding the client's needs and culminates in the delivery of finished products. This process is characterized by several key stages, each essential for ensuring that the final product meets the desired specifications and quality standards.

Initial Consultation

The first step in the OEM swimwear production process is the initial consultation. During this phase, OEM swimwear manufacturers engage with clients to discuss their specific needs and requirements. This includes understanding the brand's vision, target audience, and market trends.

OEM manufacturers often conduct market research to provide insights into current swimwear trends, helping clients make informed decisions about design and materials. This collaborative approach ensures that the final product aligns with the brand's identity and appeals to its customers.

Design Development

Once the initial consultation is complete, the next step is design development. This phase involves close collaboration between the client and the OEM swimwear manufacturer to create design concepts that reflect the brand's vision.

OEM manufacturers utilize advanced design software to create technical specifications and prototypes. This stage is crucial as it allows for the exploration of various styles, colors, and materials. The selection of materials is particularly important in swimwear production, as factors such as durability, comfort, and sustainability must be considered.

Sampling Phase

After the design concepts are finalized, the OEM swimwear manufacturer creates initial samples. These samples serve as a tangible representation of the design and allow clients to assess the quality and fit of the swimwear.

Client feedback is essential during this phase, as it may lead to revisions and adjustments to the design. The goal is to finalize a sample that meets the client's expectations and is ready for production approval. This iterative process ensures that any potential issues are addressed before moving forward.

Production Planning

With the approved sample in hand, the OEM swimwear manufacturer begins the production planning phase. This involves setting production timelines and sourcing the necessary materials and components.

Effective production planning is critical to ensure that the manufacturing process runs smoothly and meets delivery deadlines. OEM swimwear manufacturers often have established relationships with suppliers, allowing them to source high-quality materials efficiently. Additionally, they implement quality control measures before production begins to minimize the risk of defects.

Manufacturing Process

The manufacturing process is where the design comes to life. OEM swimwear manufacturers follow a structured workflow that typically includes several key steps:

- Cutting: The first step in manufacturing involves cutting the fabric according to the approved patterns. Precision is crucial at this stage to ensure that each piece is the correct size and shape.

- Sewing: After cutting, the pieces are sewn together using specialized sewing techniques. Skilled labor is essential here, as the quality of stitching can significantly impact the final product's durability and appearance.

- Quality Assurance During Production: Throughout the manufacturing process, quality assurance checks are conducted to ensure that each piece meets the required standards. This includes inspecting stitching, seams, and overall construction.

The use of advanced technology and skilled labor in the manufacturing process allows OEM swimwear manufacturers to produce high-quality swimwear that meets the demands of the market.

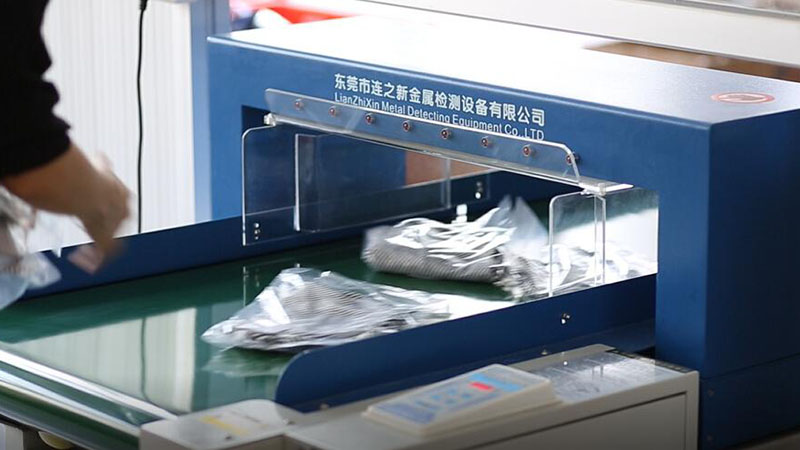

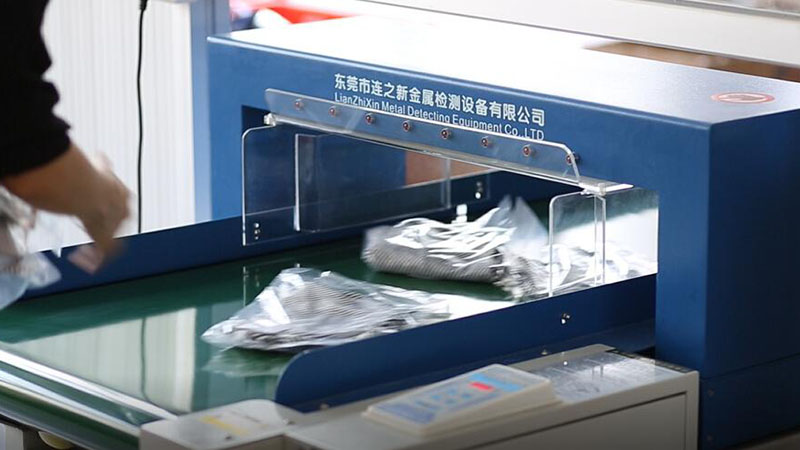

Quality Control and Assurance

Quality control is a critical aspect of the OEM swimwear production process. OEM manufacturers implement rigorous quality assurance measures to ensure that the final products meet both client specifications and industry standards.

During production, in-process quality checks are conducted to identify any defects early on. This proactive approach helps to minimize waste and ensures that any issues are addressed promptly.

Once production is complete, a final inspection is performed before shipment. This inspection includes checking for defects, ensuring that the swimwear meets the agreed-upon specifications, and verifying that all packaging requirements are met.

Packaging and Shipping

After the quality control process is complete, the swimwear is prepared for packaging and shipping. OEM swimwear manufacturers offer various packaging options to suit the client's needs, including branded packaging that enhances the product's presentation.

Logistics and shipping considerations are also crucial at this stage. OEM manufacturers work with reliable shipping partners to ensure timely delivery to clients, whether they are located domestically or internationally. Proper documentation and customs clearance are essential for international shipments, and OEM manufacturers are well-versed in these processes to facilitate smooth transactions.

Post-Production Support

The relationship between OEM swimwear manufacturers and their clients does not end with the delivery of the products. Post-production support is an essential aspect of the OEM process.

OEM manufacturers often seek client feedback after delivery to assess satisfaction and identify areas for improvement. This feedback loop is vital for continuous improvement and helps manufacturers refine their processes for future projects.

Additionally, many OEM swimwear manufacturers offer additional services, such as marketing support and inventory management, to help clients maximize their product's success in the market. Building long-term relationships with clients is a priority for OEM manufacturers, as it fosters collaboration and mutual growth.

Conclusion

The OEM swimwear production process is a multifaceted journey that requires careful planning, collaboration, and attention to detail. By working with OEM swimwear manufacturers, brands can leverage their expertise and resources to produce high-quality swimwear that meets market demands.

From the initial consultation to post-production support, each step in the process is designed to ensure that the final product aligns with the client's vision and exceeds customer expectations. As the swimwear industry continues to evolve, the role of OEM manufacturers will remain vital in helping brands navigate the complexities of production and deliver exceptional products to their customers.

Frequently Asked Questions

1. What is OEM swimwear manufacturing?

OEM swimwear manufacturing involves producing swimwear for brands under their specifications and designs. The OEM manufacturer handles the production process, allowing brands to focus on marketing and sales.

2. How long does the OEM swimwear production process take?

The timeline for OEM swimwear production can vary based on factors such as design complexity, material availability, and production capacity. Typically, the process can take several weeks to a few months from initial consultation to delivery.

3. What are the benefits of working with OEM swimwear manufacturers?

Working with OEM swimwear manufacturers offers several benefits, including access to specialized expertise, cost-effective production, high-quality materials, and the ability to scale production based on demand.

4. Can OEM swimwear manufacturers help with design development?

Yes, many OEM swimwear manufacturers offer design development services, collaborating with clients to create unique designs that align with their brand identity and market trends.

5. What quality control measures do OEM swimwear manufacturers implement?

OEM swimwear manufacturers implement various quality control measures, including in-process inspections, final product checks, and adherence to industry standards to ensure that the swimwear meets client specifications and is free from defects.