Content Menu

● Introduction to Sewing Swimwear

>> Why Sewing Swimwear is Fun

>> Challenges of Sewing Swimwear

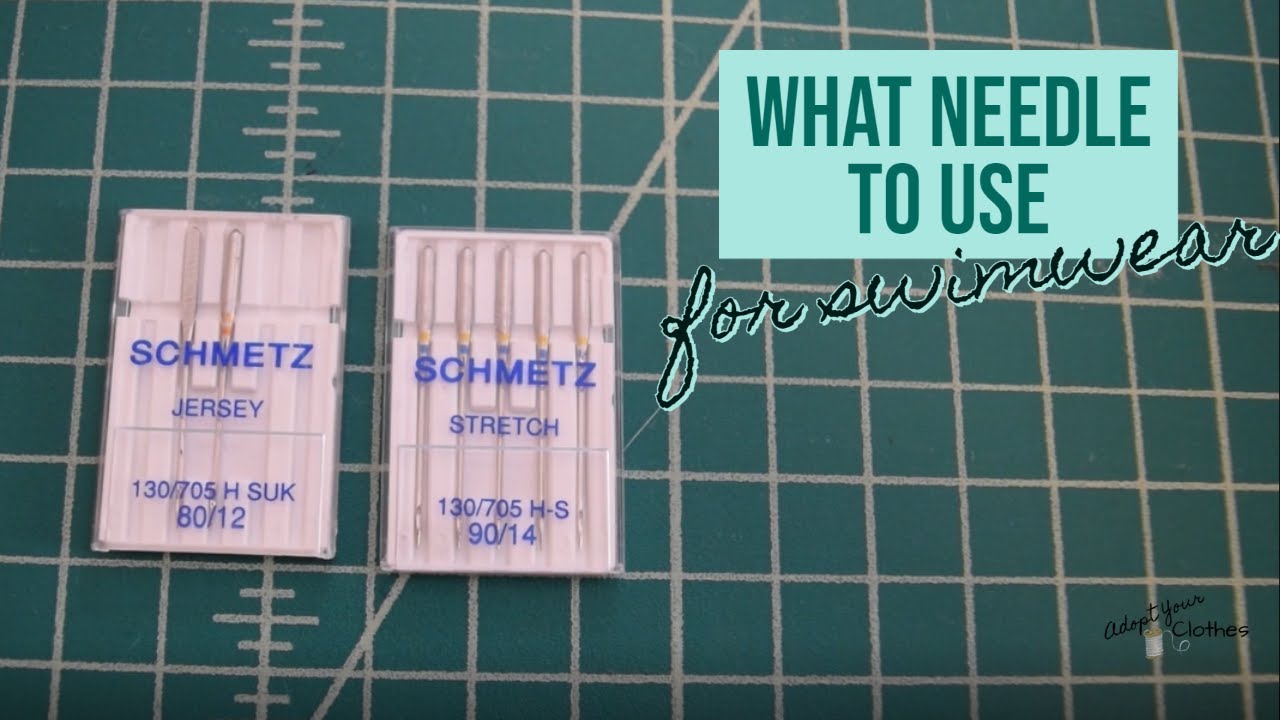

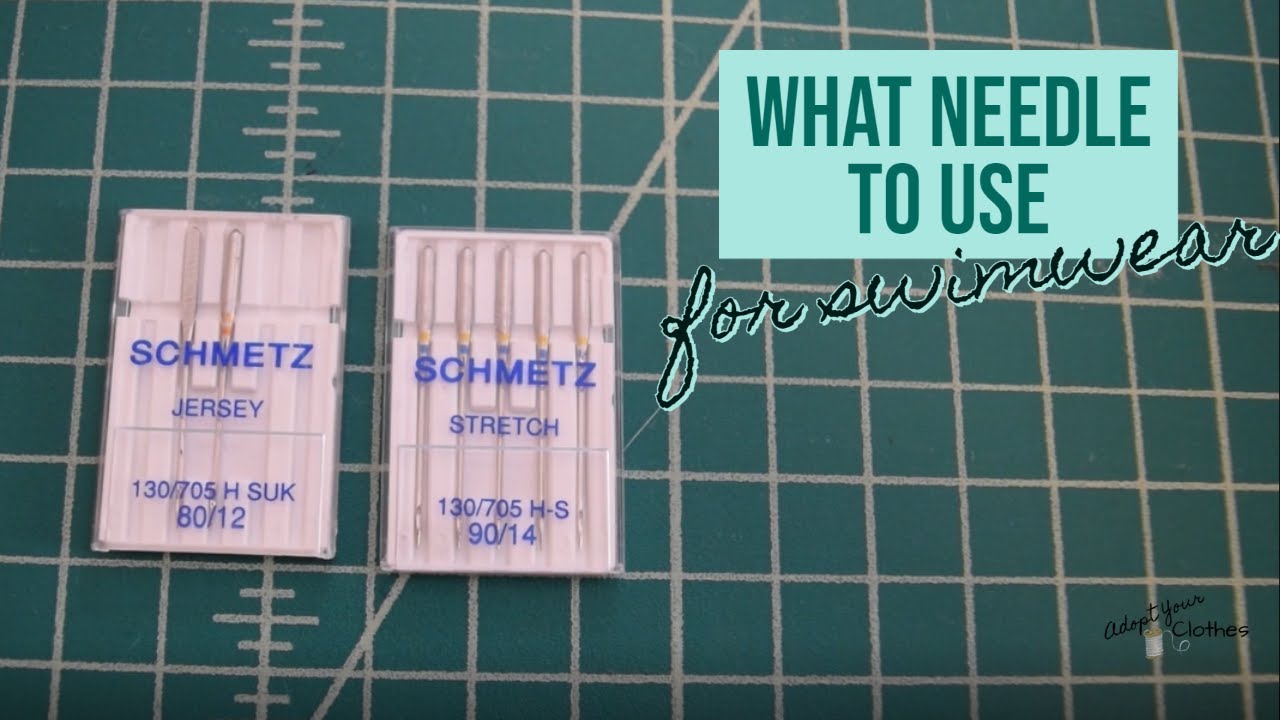

● Choosing the Right Needle for Swimwear

>> Types of Needles

>> Why Needle Size Matters

>> The Importance of Choosing the Right Needle

● Understanding Swimwear Fabrics

● Best Needles for Sewing Swimwear

>> Ballpoint Needles

>> Stretch Needles

>> Universal Needles

>> Choosing the Right Needle Size

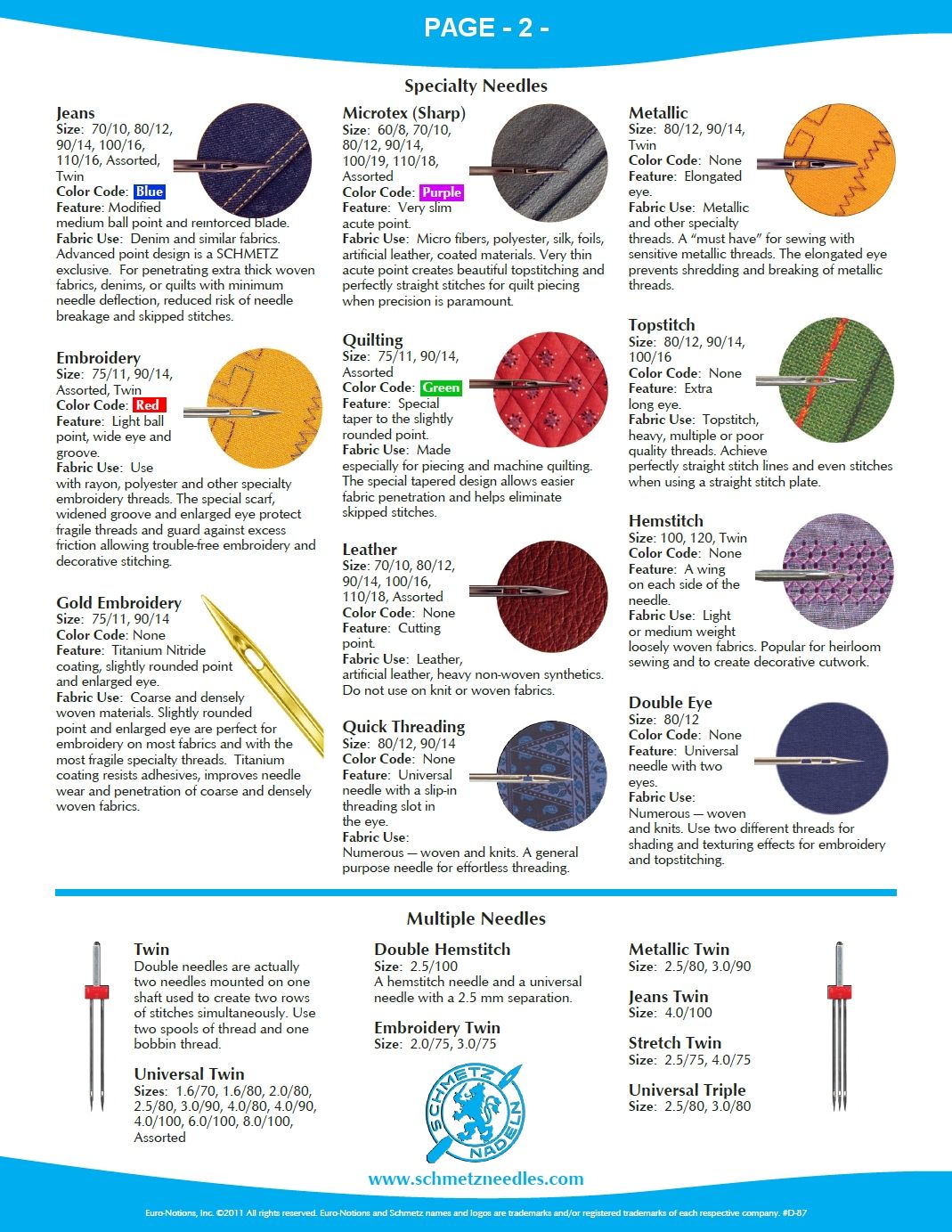

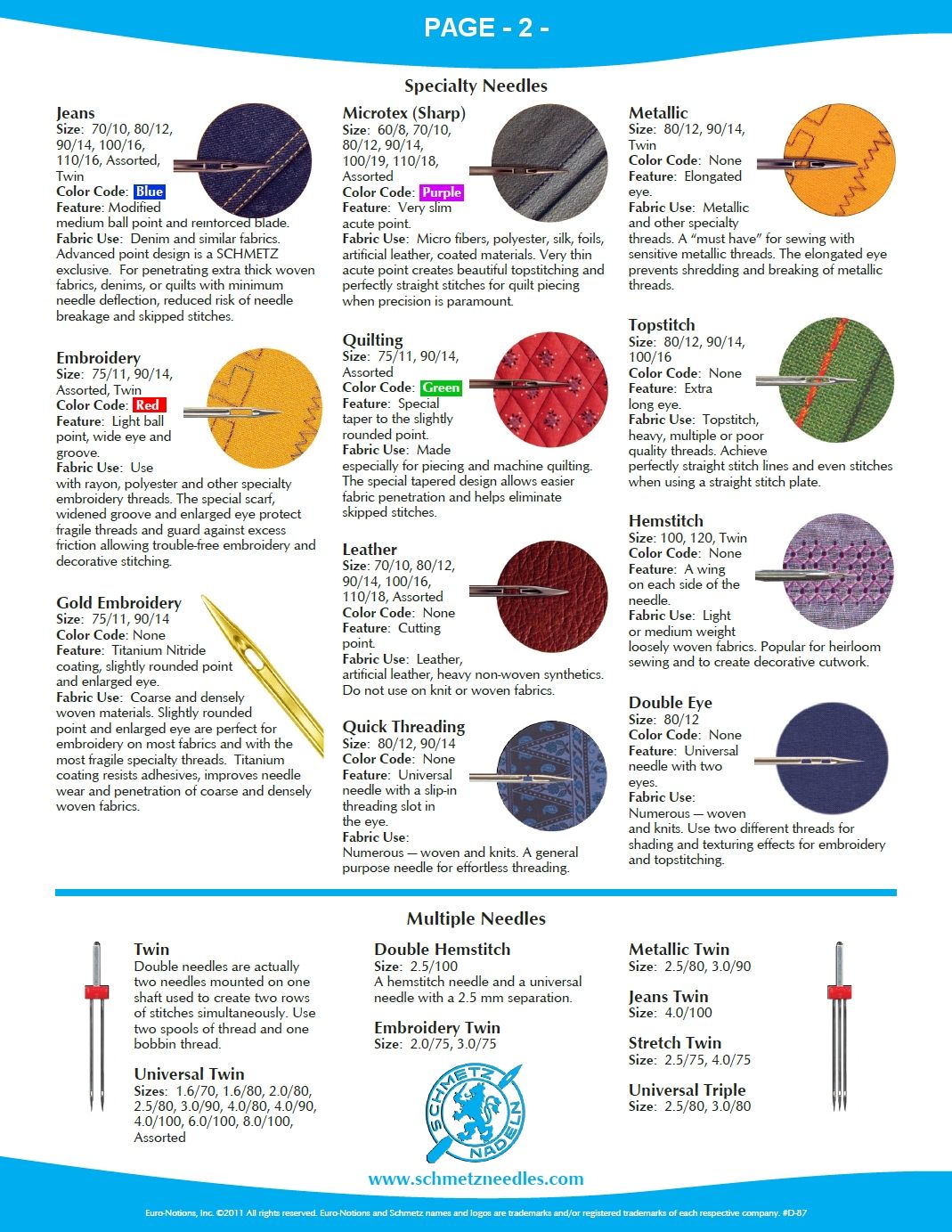

>> Needle Brands and Quality

● Tips for Sewing Swimwear

>> Using the Right Thread

>> Stitch Types

>> Handling Stretchy Fabrics

● Sewing Techniques for Swimwear

>> Stitch Type

>> Thread Selection

>> Tension Adjustment

>> Use of Stabilizers

● Common Challenges and Solutions

>> Skipped Stitches

>> Fabric Puckering

>> Wavy Seams

● Maintaining Your Needles and Equipment

● Sustainability Considerations

● Testing and Quality Control

● Summary

● Frequently Asked Questions (FAQs)

>> What is the best needle for sewing swimwear?

>> Can I use a regular sewing machine for swimwear?

>> What type of thread should I use?

Looking for the perfect needles for sewing swimwear? Discover our top picks for creating flawless, durable beach-ready garments!

As a leading Chinese swimwear manufacturing factory providing OEM services to international swimwear brands, wholesalers, and manufacturers, understanding the intricacies of swimwear production is crucial for maintaining high-quality standards and customer satisfaction. One of the most critical aspects of swimwear construction is selecting the right needle for the job. In this comprehensive guide, we'll delve deep into the world of swimwear needles, exploring the best options, techniques, and considerations to elevate your production process.

Introduction to Sewing Swimwear

Sewing swimwear can be a fun and creative experience! Making your own swimsuits lets you choose the colors, styles, and fits you love. You can create something unique that no one else has. Plus, there's a special satisfaction that comes from wearing something you made yourself. It's like stepping onto the beach in a piece of art you designed!

However, tailoring swimwear does come with some challenges. The fabrics used for swimwear are often stretchy, which can be tricky to work with. You want to make sure that your swimwear fits well and looks great. To do this, you need to pay attention to what needle you use and how you sew. This is where some handy sewing swimwear tips and a good swimwear stitching guide can help you out!

Why Sewing Swimwear is Fun

One of the best parts about sewing swimwear is being able to express your style. You can use bright patterns, fun colors, and cute designs! Every time you wear your swimwear, you get to show off your creativity. Plus, you can make it fit perfectly to your body. No more worrying if a store-bought swimsuit is the right size!

Challenges of Sewing Swimwear

Even though sewing swimwear is exciting, it can also be a bit challenging. The stretchy fabrics can sometimes be hard to handle. If you don't use the right tools, your stitches might not look nice. They could pucker or pull, which can spoil all your hard work. But with the right knowledge and tips, you can conquer these challenges and create beautiful swimwear!

Choosing the Right Needle for Swimwear

When you decide to sew swimwear, picking the right needle is super important! Different types of materials need different needles, and using the wrong one might lead to a messy swimsuit. Let's explore what needle to use for swimwear and why needle selection is so crucial.

Types of Needles

There are special needles made just for sewing stretchy fabrics, like those used in swimsuits. The two main types are ballpoint needles and stretch needles. Ballpoint needles have rounded tips, which help them slide between the fibers of the fabric. This is important because it prevents the needle from making holes in the stretchy material.

On the other hand, stretch needles are designed with a unique shape to handle elastic fabrics. They can flex and bend as you sew, which is perfect for swimwear that needs to stretch and move. Choosing between these needles can make a big difference in how your swimsuit turns out!

Why Needle Size Matters

The size of your needle can also affect your stitching a lot! If you use a needle that's too big, it might make holes in your fabric or cause it to pucker. This can ruin the look of your swimsuit. A smaller needle size is often better for lighter materials, while a slightly larger needle can work for thicker fabrics. Always check the fabric label to find out what needle size is best for your swimwear project!

The Importance of Choosing the Right Needle

When it comes to swimwear production, the choice of needle can make or break the quality of the final product. The right needle not only ensures smooth stitching but also prevents damage to delicate swimwear fabrics, reduces the likelihood of skipped stitches, and contributes to the overall durability and comfort of the garment. As an OEM manufacturer, your ability to consistently deliver high-quality swimwear depends significantly on this seemingly small but crucial component of your production process.

Understanding Swimwear Fabrics

Before we dive into the specifics of needle selection, it's essential to understand the unique characteristics of swimwear fabrics. Most modern swimwear is made from synthetic materials with high stretch properties, typically a blend of nylon and spandex (also known as Lycra or elastane). These fabrics are designed to be:

Highly elastic

Quick-drying

Resistant to chlorine and saltwater

Durable and long-lasting

Comfortable and form-fitting

The unique properties of these fabrics necessitate special considerations when it comes to needle selection and sewing techniques.

Best Needles for Sewing Swimwear

When it comes to sewing swimwear, the right needle can make all the difference. Using the best needles for sewing ensures that your stitches look great and hold strong, especially since swimwear is made from stretchy fabrics. Let's explore the best types of needles to use for sewing swimwear so you can create amazing suits!

Ballpoint Needles

Ballpoint needles are perfect for sewing swimwear because they are designed to work with knit fabrics. Unlike regular needles, ballpoint needles have a rounded tip. This rounded tip helps the needle push between the fibers of the fabric instead of piercing through them. This means your fabric won't get damaged. If you're using materials like Lycra or spandex for your swimsuit, using a ballpoint needle can help you sew without causing runs or holes.

Stretch Needles

Another great option for sewing swimwear is stretch needles. These needles are specially made to handle the elasticity of swimwear fabrics. Stretch needles have a unique design that helps them glide through stretchy materials without skipping stitches. This is super important because you want your stitches to be flexible, just like the swimwear itself. If you're working with a very stretchy fabric, consider using a stretch needle to help you achieve the best results.

Recommended sizes: 75/11 or 90/14.

Universal Needles

While not specifically designed for swimwear, universal needles can be used in some cases, especially for lighter-weight swimwear fabrics. However, they may not perform as well as stretch or ballpoint needles on highly elastic materials.

Choosing the right needle is a key step in your sewing journey. Remember that using the correct needle will lead to better sewing projects and make your swimwear not only look good but also last longer!

Choosing the Right Needle Size

The size of the needle is just as important as the type. For swimwear fabrics, the general rule is to use a finer needle to prevent large holes in the fabric. Here are some guidelines:

For lightweight to medium-weight swimwear fabrics: Use a 75/11 or 80/12 needle

For medium to heavyweight swimwear fabrics: Use a 90/14 needle

It's important to note that these are general guidelines, and you may need to adjust based on the specific fabric you're working with and the desired outcome.

Needle Brands and Quality

As an OEM manufacturer, the consistency and quality of your products are paramount. Investing in high-quality needles from reputable brands can make a significant difference in your production process. Some well-regarded needle brands include:

◆ Schmetz: Known for their high-quality stretch and ballpoint needles

◆ Organ: Offers a wide range of needles suitable for various fabrics

◆ Groz-Beckert: Provides industrial-grade needles for large-scale production

While premium needles may have a higher upfront cost, they often result in better stitch quality, reduced machine downtime, and fewer defects in the final product, ultimately leading to cost savings and improved customer satisfaction.

Tips for Sewing Swimwear

Sewing swimwear can be a lot of fun, but it also requires some special tips to make sure everything turns out great. Here are some helpful sewing swimwear tips and a swimwear stitching guide to help you succeed in your projects.

Using the Right Thread

When you're making swimwear, the type of thread you use is very important. You should use polyester or nylon thread. These threads are strong and stretchy, which means they can handle the movements you make while swimming. This will help your swimsuits last longer and look better, even when wet!

Stitch Types

The stitches you choose can change how your swimwear feels and fits. For swimwear, it's best to use zigzag stitches or overlock stitches. Zigzag stitches allow the fabric to stretch without breaking the thread, while overlock stitches help finish the edges neatly to prevent fraying. Choosing the right stitch type is key for a comfortable fit.

Handling Stretchy Fabrics

Stretchy fabrics can be tricky! When you sew, make sure to keep the fabric flat and don't pull it too much. If you pull too hard, your fabric might pucker or stretch out of shape. You can use a walking foot on your sewing machine to help keep the fabric moving smoothly. This makes it easier to sew without any problems.

Sewing Techniques for Swimwear

Choosing the right needle is only part of the equation. To achieve the best results in swimwear production, it's essential to pair the correct needle with appropriate sewing techniques. Here are some key considerations:

Stitch Type

For swimwear, the most commonly used stitches are:

◆ Zigzag stitch: Provides stretch and flexibility

◆ Overlock stitch: For seaming and finishing edges

◆ Coverstitch: For hems and decorative stitching

When using a standard sewing machine, a narrow zigzag stitch is often the best choice for constructing swimwear [5]. The width and length of the zigzag should be adjusted based on the fabric's stretch and the desired finish.

Thread Selection

Choose a thread that complements your needle and fabric choice. For swimwear, consider using:

◆ Polyester thread: Durable and resistant to chlorine and saltwater

◆ Nylon thread: Offers good stretch and recovery

◆ Wooly nylon: Ideal for serging and provides excellent stretch

Tension Adjustment

Proper tension is crucial when sewing swimwear fabrics. Too much tension can cause the fabric to pucker or the stitches to break when stretched. Too little tension can result in loose, unsightly seams. Always test your tension on a scrap piece of the swimwear fabric before beginning production.

Use of Stabilizers

In some cases, using a stabilizer can help prevent stretching and distortion during the sewing process. Water-soluble stabilizers are particularly useful for swimwear, as they can be easily removed after sewing without leaving any residue.

Common Challenges and Solutions

Even with the right needle and techniques, you may encounter some challenges when sewing swimwear. Here are some common issues and their solutions:

Skipped Stitches

If you're experiencing skipped stitches, try the following:

◆ Change to a fresh needle

◆ Adjust the tension

◆ Slow down the sewing speed

◆ Use a stretch or ballpoint needle if you haven't already

Fabric Puckering

To prevent puckering:

◆ Reduce the presser foot pressure

◆ Use a walking foot attachment

◆ Adjust the differential feed on your serger

Wavy Seams

To achieve smooth seams:

◆ Use a stabilizer

◆ Adjust the differential feed

◆ Experiment with different stitch lengths

Maintaining Your Needles and Equipment

To ensure consistent quality in your OEM swimwear production, it's crucial to maintain your needles and sewing equipment properly:

◆ Change needles regularly: A good rule of thumb is to change needles after every 8 hours of sewing or at the start of each new project.

◆ Clean your machines: Regular cleaning prevents lint buildup, which can affect stitch quality.

◆ Oil your machines: Proper lubrication ensures smooth operation and extends the life of your equipment.

◆ Store needles properly: Keep needles in a dry, cool place to prevent rust and damage.

Sustainability Considerations

As sustainability becomes increasingly important in the fashion industry, consider how your needle and thread choices can contribute to more eco-friendly swimwear production:

◆ Opt for durable, high-quality needles that need to be replaced less frequently

◆ Choose threads made from recycled materials when possible

◆ Implement a needle recycling program in your factory

Testing and Quality Control

Implementing a robust testing and quality control process is essential for maintaining high standards in your OEM swimwear production. Consider the following:

◆ Conduct regular needle checks to ensure they're not bent or damaged

◆ Perform stretch tests on seams to ensure they can withstand the stress of wear

◆ Implement a system for tracking needle usage and replacement

◆ Regularly review and update your needle selection based on new developments in swimwear fabrics and sewing technology

Summary

In this blog post, we explored the exciting world of sewing swimwear. We learned that sewing swimwear can be a fun and creative activity. It allows you to make your own stylish swimsuits, but it also comes with some challenges. Understanding sewing swimwear tips and following a swimwear stitching guide can help you overcome those hurdles.

A big part of sewing swimwear is choosing the right needle. We discussed what needle to use for swimwear, emphasizing the importance of needle selection. The best needles for sewing swimwear include ballpoint needles and stretch needles. Ballpoint needles are great for knit fabrics, while stretch needles can handle the stretchy materials used in swimwear.

We also shared useful sewing swimwear tips. Using the right thread, like polyester or nylon, helps ensure your swimwear is strong and stretchy. Additionally, choosing the best stitch types, such as zigzag stitches or overlock stitches, can make a big difference. Finally, handling stretchy fabrics correctly is key to keeping your swimwear looking great without any puckering.

For those looking to take their skills further, we looked at advanced techniques for tailoring swimwear. Adding elastic properly can create a snug fit, and customizing designs allows for unique and personal swimwear. Overall, understanding these elements will help you successfully sew your own swimwear!

Frequently Asked Questions (FAQs)

Welcome to the Frequently Asked Questions section about sewing swimwear! Here, we will answer some common questions that you might have. Whether you are just starting or have some experience, these answers can help you on your sewing journey.

What is the best needle for sewing swimwear?

The best needles for sewing swimwear are ballpoint needles and stretch needles. Ballpoint needles are great because they can slide between the threads of knit fabrics without causing holes. Stretch needles are super helpful too, as they are designed to handle the stretchy fabrics often used in swimsuits. Using the right needle ensures that your stitches look good and your swimwear fits well.

Can I use a regular sewing machine for swimwear?

Yes, you can absolutely use a regular sewing machine for swimwear! Just make sure to adjust the settings and use the right needles. You might want to use a zigzag or overlock stitch to keep the seams strong and stretchy. This way, your machine can handle the fabric without any trouble.

What type of thread should I use?

When sewing swimwear, it's best to use polyester or nylon thread. These types of thread are strong and stretchy, making them perfect for swimwear that needs to hold up in water and while being worn. Using the right thread will help your swimwear last longer and look great.