Content Menu

● The Shift Towards Sustainability

● Understanding Sustainable Materials

● Ethical Labor Practices

● Reducing Waste Through Customization

● Innovative Production Techniques

● Community Engagement and Education

● The Impact of Certifications

● The Future of Custom Made Swimwear

● Consumer Responsibility

● The Role of Technology

● Collaborations and Partnerships

● Conclusion

● Frequently Asked Questions

>> 1. What materials do custom made swimwear manufacturers use for sustainable production?

>> 2. How do custom made swimwear manufacturers ensure ethical labor practices?

>> 3. What are the benefits of custom made swimwear?

>> 4. How do innovative production techniques contribute to sustainability?

>> 5. What certifications should I look for in sustainable swimwear?

In recent years, the fashion industry has faced increasing scrutiny regarding its environmental impact and ethical practices. This is particularly true for the swimwear sector, where the use of synthetic materials and the production processes can contribute significantly to pollution and waste. However, custom made swimwear manufacturers are stepping up to the challenge, embracing sustainable and ethical production methods that not only benefit the environment but also promote fair labor practices. This article explores how these manufacturers are making a difference, the materials they use, the production processes they adopt, and the overall impact on the industry.

The Shift Towards Sustainability

The shift towards sustainability in the swimwear industry is driven by consumer demand for eco-friendly products. More and more consumers are becoming aware of the environmental issues associated with fast fashion and are seeking alternatives that align with their values. Custom made swimwear manufacturers are responding to this demand by incorporating sustainable practices into their production processes.

Understanding Sustainable Materials

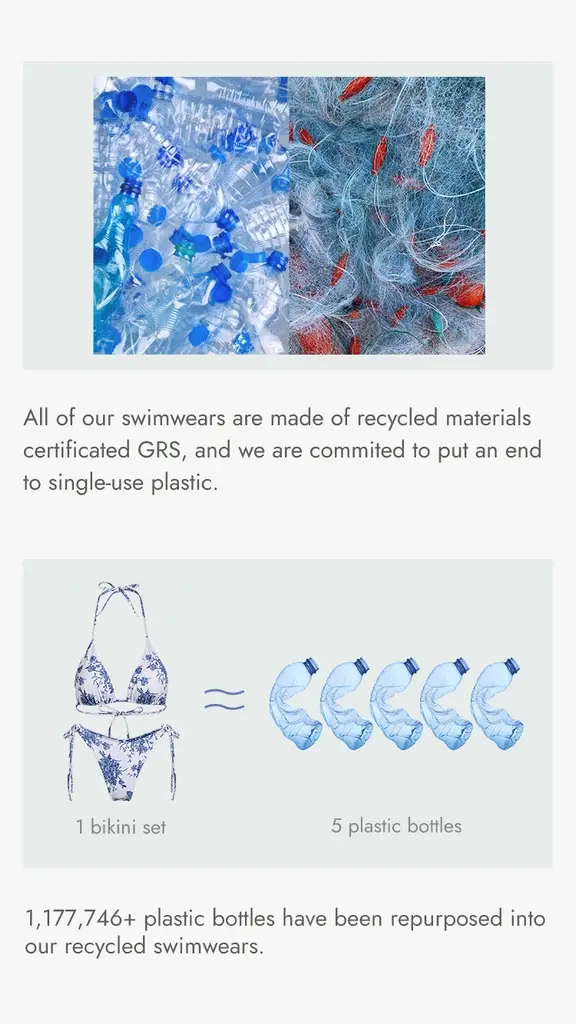

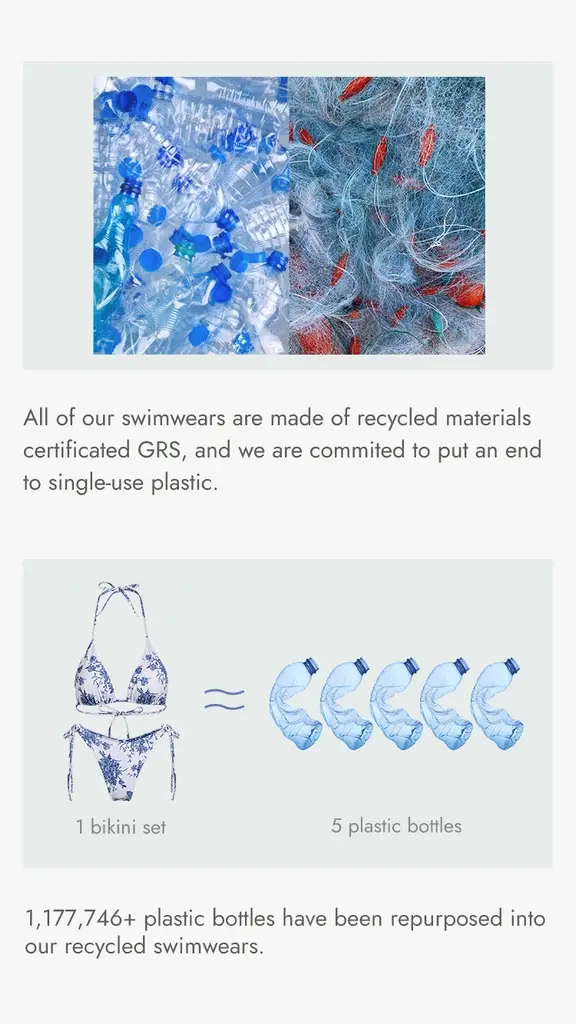

One of the primary ways custom made swimwear manufacturers support sustainable production is through the use of eco-friendly materials. Traditional swimwear is often made from nylon and polyester, which are derived from petroleum and are not biodegradable. In contrast, many manufacturers are now using recycled materials, such as recycled nylon and polyester, which help reduce waste and lower the carbon footprint associated with production.

Additionally, some manufacturers are exploring innovative materials such as Econyl, a regenerated nylon made from discarded fishing nets and other nylon waste. This not only helps to clean up the oceans but also provides a high-quality material for swimwear that is durable and long-lasting. The use of such materials is a testament to the commitment of custom made swimwear manufacturers to not only create beautiful products but also to protect the environment.

Ethical Labor Practices

Sustainability is not just about materials; it also encompasses the ethical treatment of workers. Custom made swimwear manufacturers are increasingly focusing on fair labor practices, ensuring that their workers are paid fair wages and work in safe conditions. Many manufacturers are committed to transparency in their supply chains, allowing consumers to see where and how their swimwear is made.

By partnering with factories that adhere to ethical labor standards, custom made swimwear manufacturers can provide consumers with peace of mind that their purchases support fair labor practices. This commitment to ethical production is becoming a key selling point for many brands, as consumers are more likely to support companies that prioritize social responsibility.

Reducing Waste Through Customization

One of the significant advantages of custom made swimwear is the reduction of waste associated with overproduction. Traditional swimwear brands often produce large quantities of stock in various sizes and styles, leading to excess inventory that may end up in landfills. In contrast, custom made swimwear manufacturers create products based on specific customer orders, minimizing waste and ensuring that each piece is made to fit the individual.

This made-to-order approach not only reduces waste but also allows for greater creativity and personalization. Customers can choose their designs, colors, and sizes, resulting in unique swimwear that reflects their style while supporting sustainable practices. This level of customization fosters a deeper connection between the consumer and the product, as each piece is tailored to individual preferences.

Innovative Production Techniques

Custom made swimwear manufacturers are also adopting innovative production techniques that further enhance sustainability. For example, some brands are utilizing 3D printing technology to create swimwear patterns, which reduces fabric waste and allows for precise fitting. This technology can significantly decrease the amount of material wasted during the cutting process, making it a more sustainable option.

Moreover, manufacturers are increasingly using digital printing methods, which consume less water and energy compared to traditional dyeing processes. Digital printing allows for vibrant designs without the need for harmful chemicals, making it a more environmentally friendly option. This shift not only benefits the environment but also allows for quicker turnaround times and more flexibility in design.

Community Engagement and Education

Many custom made swimwear manufacturers are also engaging with their communities to promote sustainability and ethical practices. This includes educating consumers about the importance of sustainable fashion and encouraging them to make informed choices. Brands often share their stories, production processes, and the impact of their materials on their websites and social media platforms.

By fostering a sense of community and encouraging dialogue around sustainability, these manufacturers are helping to create a more informed consumer base that values ethical production. Workshops, webinars, and social media campaigns are just a few ways brands are reaching out to educate their customers about the benefits of sustainable swimwear.

The Impact of Certifications

To further validate their commitment to sustainability, many custom made swimwear manufacturers seek certifications from recognized organizations. Certifications such as Global Organic Textile Standard (GOTS), OEKO-TEX, and Fair Trade provide consumers with assurance that the products they are purchasing meet specific environmental and social criteria.

These certifications not only enhance the credibility of the brands but also encourage other manufacturers to adopt sustainable practices, creating a ripple effect throughout the industry. As more brands pursue these certifications, the overall standard for sustainability in the swimwear industry is raised, benefiting both consumers and the environment.

The Future of Custom Made Swimwear

As the demand for sustainable and ethical swimwear continues to grow, custom made swimwear manufacturers are well-positioned to lead the charge. By prioritizing eco-friendly materials, ethical labor practices, and innovative production techniques, these manufacturers are setting a new standard for the industry.

The future of swimwear lies in customization, sustainability, and ethical production. As consumers become more conscious of their purchasing decisions, custom made swimwear manufacturers will play a crucial role in shaping a more sustainable fashion landscape. This shift not only benefits the environment but also empowers consumers to make choices that align with their values.

Consumer Responsibility

While custom made swimwear manufacturers are making significant strides towards sustainability, consumers also play a vital role in this movement. By choosing to support brands that prioritize ethical production and sustainable materials, consumers can drive demand for more responsible practices in the fashion industry.

Additionally, consumers can extend the life of their swimwear by caring for it properly, opting for repairs instead of replacements, and recycling or donating old swimwear. This collective effort can significantly reduce the environmental impact of swimwear production and consumption.

The Role of Technology

Technology is also playing a crucial role in the evolution of sustainable swimwear. From advanced fabric technologies that enhance durability and reduce waste to online platforms that facilitate custom orders, technology is enabling manufacturers to operate more sustainably.

For instance, some brands are using artificial intelligence to predict trends and manage inventory more effectively, reducing the likelihood of overproduction. This integration of technology not only streamlines operations but also aligns with the principles of sustainability.

Collaborations and Partnerships

Collaborations between custom made swimwear manufacturers and environmental organizations are becoming increasingly common. These partnerships can lead to innovative solutions for reducing waste and promoting sustainability. For example, some brands collaborate with ocean conservation groups to raise awareness about marine pollution and contribute a portion of their profits to cleanup efforts.

Such collaborations not only enhance the brand's credibility but also demonstrate a commitment to making a positive impact on the environment. By working together, manufacturers and organizations can amplify their efforts and reach a broader audience.

Conclusion

In conclusion, custom made swimwear manufacturers are making significant strides in supporting sustainable and ethical production. Through the use of eco-friendly materials, commitment to fair labor practices, and innovative production techniques, these manufacturers are not only reducing their environmental impact but also promoting social responsibility. As the industry continues to evolve, the focus on sustainability will only grow, paving the way for a more ethical and environmentally friendly future in swimwear fashion.

The journey towards sustainability is ongoing, and it requires the collective effort of manufacturers, consumers, and organizations. By embracing sustainable practices and supporting ethical production, we can all contribute to a healthier planet and a more equitable fashion industry.

Frequently Asked Questions

1. What materials do custom made swimwear manufacturers use for sustainable production?

Custom made swimwear manufacturers often use recycled materials such as recycled nylon and polyester, as well as innovative fabrics like Econyl, which is made from regenerated nylon.

2. How do custom made swimwear manufacturers ensure ethical labor practices?

Many manufacturers partner with factories that adhere to fair labor standards, ensuring workers are paid fair wages and work in safe conditions. They also promote transparency in their supply chains.

3. What are the benefits of custom made swimwear?

Custom made swimwear reduces waste associated with overproduction, allows for personalized designs, and ensures a better fit for the individual.

4. How do innovative production techniques contribute to sustainability?

Techniques such as 3D printing and digital printing reduce fabric waste and minimize the use of harmful chemicals, making the production process more environmentally friendly.

5. What certifications should I look for in sustainable swimwear?

Look for certifications such as Global Organic Textile Standard (GOTS), OEKO-TEX, and Fair Trade, which indicate that the products meet specific environmental and social criteria.