Content Menu

● Introduction to Swimwear Manufacturing

>> What are Swimwear Manufacturers?

>> Why Swimwear is Special

● Product Launch Timeline

>> Design and Development

>> Testing and Feedback

>> Final Production

● Improving Production Efficiency

>> Automation in Manufacturing

>> Skilled Workforce

● Managing the Supply Chain

>> Sourcing Materials

>> Logistics and Delivery

● Reducing Costs and Time-to-Market

>> Bulk Purchasing

>> Streamlining Processes

● Choosing the Right Manufacturing Partners

>> Qualities to Look For

>> Building Strong Relationships

● Conclusion

● Frequently Asked Questions (FAQs)

>> What is the most important step in swimwear manufacturing?

>> How long does it take to launch a new swimwear product?

>> How do manufacturers ensure the quality of swimwear?

Discover the secrets behind how swimwear manufacturers are cutting time and speeding up product launches in this eye-opening post!

Introduction to Swimwear Manufacturing

Welcome to the exciting world of swimwear manufacturing! This is where all the fun and stylish swimsuits that we see at the beach or pool are created. Swimwear manufacturers are the people and companies that design, produce, and distribute a variety of swimwear. They play a very important role in making sure we have everything we need for a day in the sun, whether it's bikinis, swim trunks, or swim shirts.

What are Swimwear Manufacturers?

Swimwear manufacturers create many types of swimwear. This includes popular items like bikinis, which are two-piece swimsuits, and swim trunks, which are typically worn by boys and men. There are also swim shirts designed to keep you safe from the sun. These manufacturers take special care to design swimsuits that are not only fun to wear but also comfortable and functional.

Why Swimwear is Special

Making swimwear is a unique challenge! The materials used in swimwear are specially chosen to help us enjoy our time in the water. Many swimsuits are made from quick-dry fabric, so when we get out of the pool or ocean, they dry off quickly. Some fabrics even have UV protection to help keep our skin safe from the sun's rays. This means that swimwear manufacturers have to think really carefully about the fabrics and features they use to make sure we can have fun, stay safe, and look good while doing it!

Product Launch Timeline

When swimwear manufacturers want to launch a new product, they follow a special plan called a product launch timeline. This timeline helps them stay organized and ensures everything is done at the right time. Each step in the timeline is important to make sure the swimwear is a success.

Design and Development

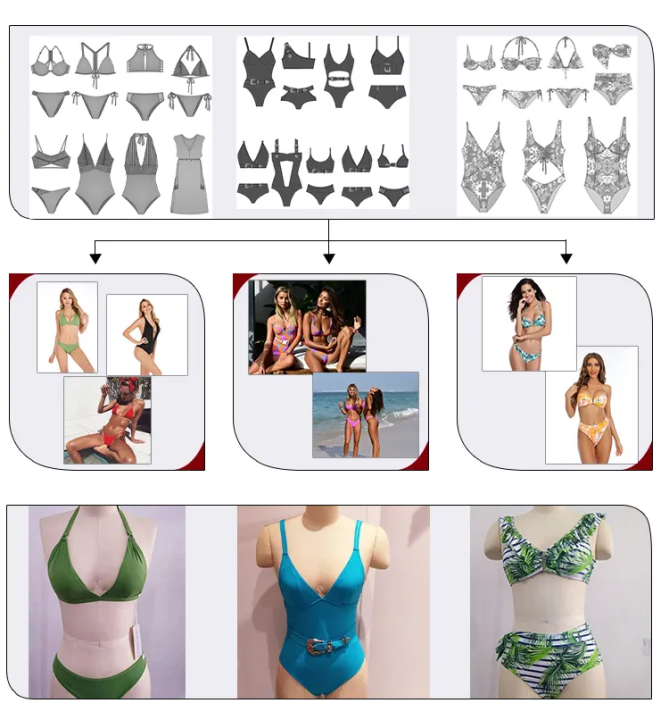

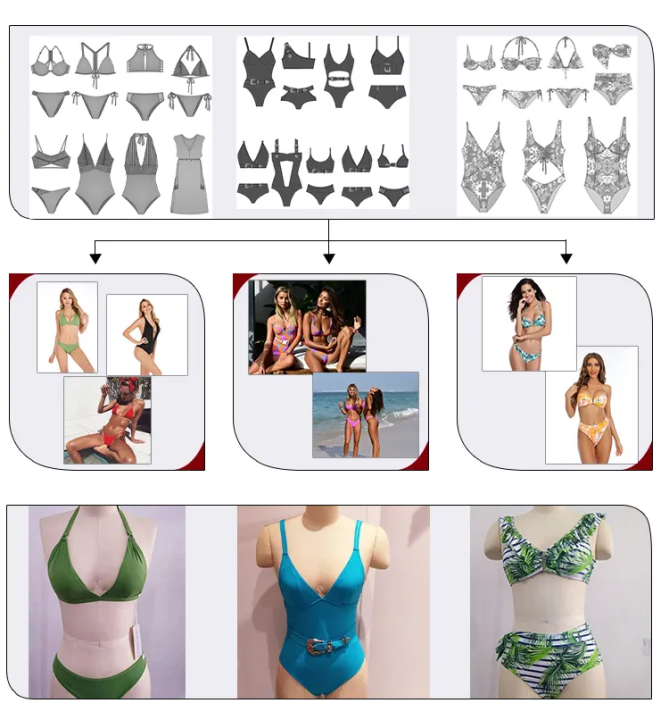

The first step in the product launch timeline is design and development. Designers think of cool ideas for new swimwear, like fun patterns or unique styles. They draw sketches and then create prototypes. Prototypes are like practice versions of the swimwear. They help everyone see what the final product will look like and feel like.

Testing and Feedback

Once the prototypes are ready, it's time for testing and feedback. Swimwear manufacturers let people try on the new designs. They check if the swimwear is comfortable, fits well, and lasts a long time. After testing, the manufacturers gather feedback from the testers. This feedback is super important because it helps the designers make improvements. They want to ensure the swimwear is perfect before making it for everyone to buy.

Final Production

The last step in the product launch timeline is final production. This is where the swimwear is made in large quantities. Once the design is approved, the manufacturers set up their machines and start sewing lots of swimsuits. They have to make sure everything is just right so that when the swimwear hits the stores, it is ready for beach fun!

Improving Production Efficiency

Making swimwear is a fun and creative process, but it also needs to be quick and smart. This is where production efficiency comes into play. When swimwear manufacturers work efficiently, they can make more products in less time. This not only saves money but also helps them get their designs to stores faster.

Automation in Manufacturing

One way to improve production efficiency is through automation. Automation means using machines to help with making swimwear. For example, instead of sewing every piece by hand, machines can do some of these tasks. This speeds up production and helps workers focus on more complex tasks. When machines take care of simple jobs, it means that swimwear can be made faster and more accurately.

Skilled Workforce

While machines are super helpful, having a skilled workforce is just as important. Skilled workers know how to handle the machines and can fix any problems that come up. They also understand how to make the swimwear look great and feel comfortable. By having a team of well-trained people, swimwear manufacturers can produce high-quality products more quickly. This combination of machines and skilled workers is key to making the manufacturing process run smoothly.

Managing the Supply Chain

Swimwear manufacturers have a big job! They need to make sure everything runs smoothly while creating fun and colorful swimwear. One important part of this process is called supply chain management. This means organizing everything from getting materials to delivering the finished swimsuits to stores.

Sourcing Materials

The first step in managing the supply chain is sourcing materials. This is where manufacturers find the best fabrics and supplies they need to make swimsuits. They look for materials that are comfortable, durable, and even special ones that can dry quickly or protect against the sun. To do this, manufacturers work closely with different suppliers to ensure they have everything they need to create the best swimwear.

Logistics and Delivery

Once the materials are ready, the next challenge is logistics and delivery. This means manufacturers must plan how to move the materials to their factories and then how to ship the finished swimsuits to stores. Good planning helps make sure everything arrives on time. By managing the delivery process well, swimwear manufacturers can avoid delays and keep their customers happy.

In summary, managing the supply chain is super important for swimwear manufacturers. They work hard to find the right materials and ensure everything is delivered properly. This helps them create great swimwear that everyone can enjoy!

Reducing Costs and Time-to-Market

When swimwear manufacturers want to be successful, they need to think about two important things: cost reduction and time-to-market. Cost reduction means finding ways to spend less money while making swimwear. Time-to-market is about how fast they can create and sell new swimwear products. Getting these things right helps manufacturers stay ahead of the competition.

Bulk Purchasing

One smart way swimwear manufacturers can reduce costs is through bulk purchasing. This means buying a lot of materials at once instead of just a few. When they buy in bulk, they can often get a better price. It's like buying a big pack of your favorite snacks at the store. The more you buy, the cheaper each snack becomes! This helps manufacturers save money, which they can use to make even better swimwear.

Streamlining Processes

Another way to help with cost reduction and speed up time-to-market is by streamlining processes. This means making things easier and faster. For example, if the design and production steps are organized well, everyone knows what to do and when to do it. This can cut down on mistakes and wasted time. When swimwear manufacturers simplify their processes, they can create new swimwear products more quickly and at a lower cost. It's like cleaning up your room. When everything is in the right place, you can find your toys faster and play with them sooner!

Choosing the Right Manufacturing Partners

When it comes to making swimwear, choosing the right manufacturing partners is very important. These partners help bring swimwear ideas to life. If you pick the best ones, your swimwear can be made faster and better. Here are some things to think about when choosing these partners.

Qualities to Look For

First, you need to know what makes a good manufacturing partner. One key quality is reliability. This means they should always deliver on time and keep their promises. If a partner is late with materials, it can slow down everything and delay your swimwear launch. Another important quality is the ability to maintain high quality. Swimwear needs to be comfy and durable, so the partner must know how to make great products.

Building Strong Relationships

It's not just about picking the right partner; you also need to build strong relationships with them. This means talking openly and often. When you work closely with your manufacturing partners, it helps everyone understand each other better. Good communication can lead to better cooperation. When everyone is on the same page, it makes the whole process smoother, leading to better results in the end.

Conclusion

In the exciting world of swimwear manufacturing, many important steps come together to create the final products we love to wear. From the designs that start the journey to the feedback that helps make swimsuits better, every part plays a vital role. Swimwear manufacturers work hard to ensure that each piece is not only stylish but also comfortable and durable.

By improving production efficiency and managing the supply chain effectively, manufacturers can save time and money. This is key to getting new swimwear into stores faster. They also focus on cost reduction and time-to-market strategies, which help keep prices reasonable while still offering great quality.

Choosing the right manufacturing partners is another important aspect. Good partners bring reliability, quality, and teamwork to the table, helping manufacturers create swimsuits that meet everyone's needs. Strong relationships with these partners mean better cooperation and results, leading to happy customers.

Overall, swimwear manufacturing is a team effort that combines creativity, technology, and smart business practices. With all these components working together, we can enjoy amazing swimwear that enhances our time at the beach or pool. So, whether you're wearing a bikini, trunks, or a swim shirt, remember that a lot goes into making the swimwear you love!

Frequently Asked Questions (FAQs)

What is the most important step in swimwear manufacturing?

The most important step in swimwear manufacturing is the design and development phase. This is where creative designers think of fun and stylish swimwear ideas. They create prototypes, which are sample versions of the swimwear. This step is crucial because it sets the stage for everything that follows. If the design is not good, it can affect how the product looks and feels. A great design can lead to a successful swimwear line!

How long does it take to launch a new swimwear product?

The time it takes to launch a new swimwear product can vary, but it usually takes several months. From the moment the designers start sketching ideas to when the final product is ready for stores, it can take anywhere from six months to a year. This includes all the steps like designing, testing, and final production. Each step is important, and rushing through can lead to problems later on.

How do manufacturers ensure the quality of swimwear?

Manufacturers make sure swimwear is high-quality through careful testing and feedback. They test prototypes for comfort, fit, and durability. This means they see how well the swimwear holds up when people wear it. If something isn't right, they use feedback to make improvements. Additionally, they work with trusted suppliers to get the best materials. By following these steps, swimwear manufacturers can create great products that people love to wear.