Content Menu

● Introduction

● Understanding the Swimwear Manufacturing Process

>> Overview of the Swimwear Production Process

>> Key Factors That Influence Quality in Swimwear Manufacturing

● Selecting the Right Wholesale Swimwear Manufacturer

>> Researching Potential Manufacturers

>> Evaluating Manufacturer Capabilities

● Quality Assurance Practices

>> Importance of Quality Control (QC) Measures

>> Key QC Practices to Look For

>> Certifications and Standards to Consider

● Communication and Collaboration

>> Establishing Clear Communication Channels

>> Importance of Detailed Specifications and Expectations

>> Building a Collaborative Relationship with Manufacturers

● Sampling and Prototyping

>> Importance of Requesting Samples Before Bulk Orders

>> Evaluating Samples for Quality and Fit

>> Making Adjustments Based on Feedback

● Logistics and Supply Chain Considerations

>> Understanding Shipping and Handling Processes

>> Importance of Timely Delivery and Inventory Management

>> Strategies for Minimizing Risks in the Supply Chain

● Post-Production Quality Checks

>> Conducting Inspections Upon Receipt of Goods

>> Handling Defects and Returns

>> Continuous Improvement Feedback Loop

● Conclusion

● Additional Resources

● Frequently Asked Questions

>> 1. What should I look for in a wholesale swimwear manufacturer?

>> 2. How can I ensure the quality of swimwear samples?

>> 3. What certifications should a swimwear manufacturer have?

>> 4. How important is communication with manufacturers?

>> 5. What are the risks of sourcing from wholesale swimwear manufacturers?

Introduction

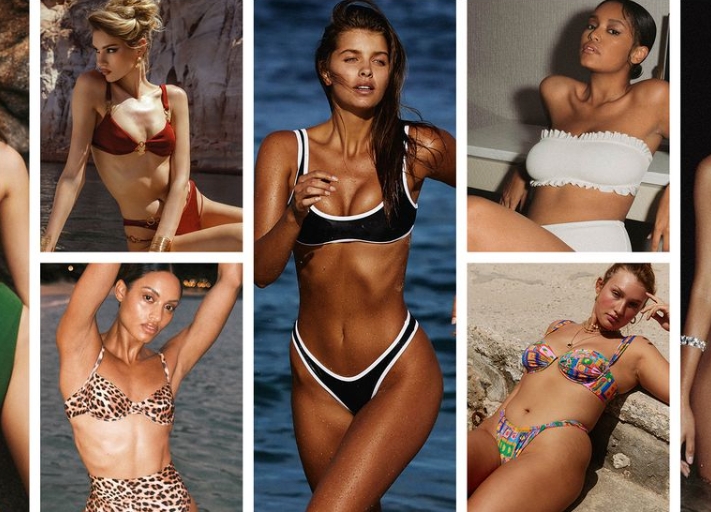

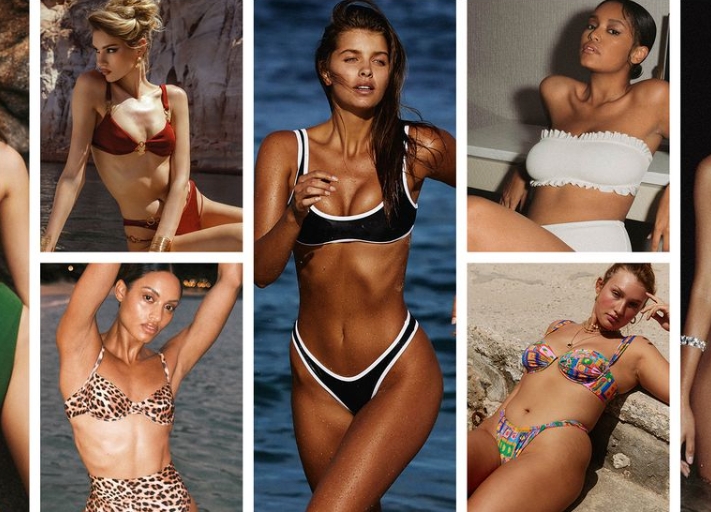

In the competitive world of swimwear, quality is paramount. As a swimwear brand or wholesaler, the quality of your products can significantly impact your reputation and sales. Sourcing from wholesale swimwear manufacturers can be a cost-effective solution, but it comes with its own set of challenges. This article aims to guide you through the process of ensuring quality when sourcing from wholesale swimwear manufacturers, providing insights and best practices to help you make informed decisions.

Understanding the Swimwear Manufacturing Process

The swimwear manufacturing process involves several critical steps that can affect the final product's quality. Understanding these steps is essential for anyone looking to source swimwear effectively.

Overview of the Swimwear Production Process

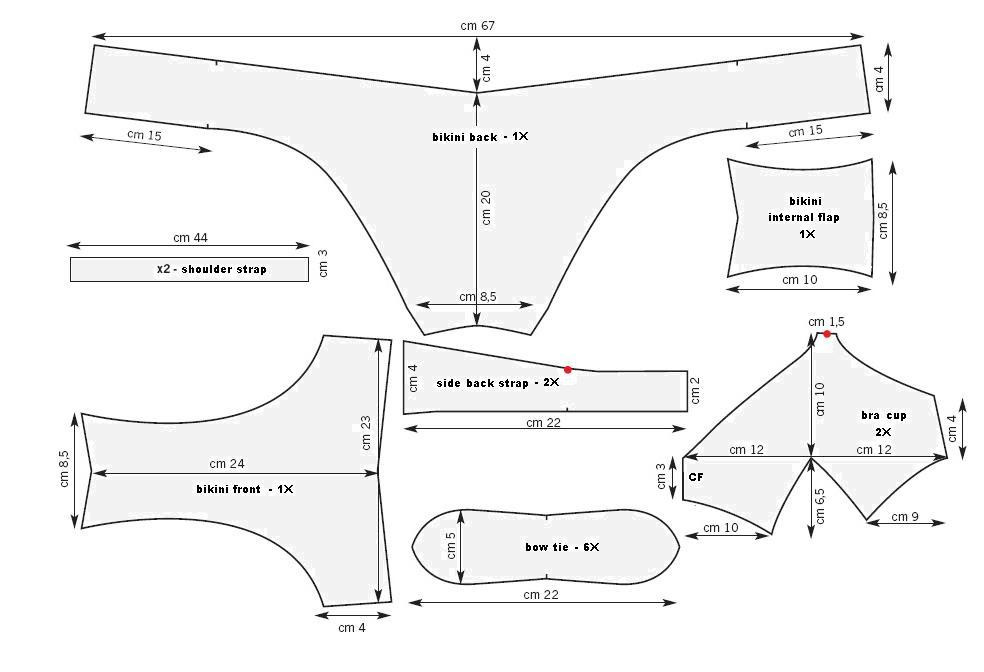

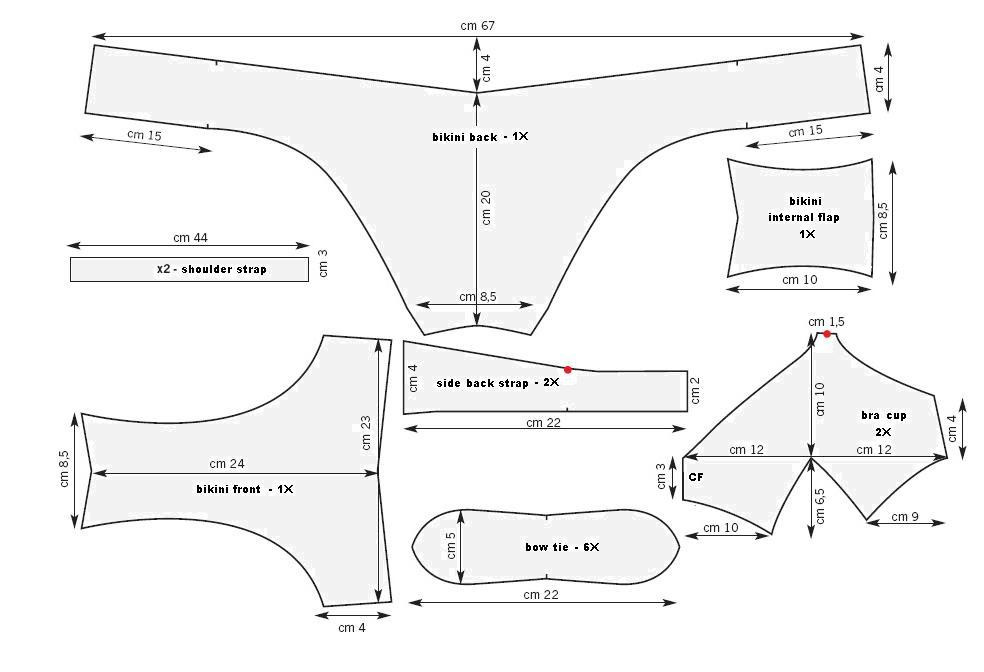

1. Design and Prototyping: The journey begins with design. Designers create swimwear that meets current trends and customer preferences. Prototyping allows for testing designs before mass production.

2. Material Selection: Choosing the right materials is crucial. Fabrics must be durable, stretchy, and resistant to chlorine and UV rays. Common materials include nylon, polyester, and spandex.

3. Production Techniques: Different techniques, such as flatlock stitching and heat bonding, can enhance the quality and comfort of swimwear. Understanding these techniques can help you choose the right manufacturer.

Key Factors That Influence Quality in Swimwear Manufacturing

Several factors can influence the quality of swimwear, including:

- Fabric Quality: The type and quality of fabric used can determine the swimwear's durability and comfort.

- Manufacturing Techniques: Advanced techniques can improve fit and longevity.

- Quality Control Measures: Effective quality control processes ensure that defects are caught early.

Selecting the Right Wholesale Swimwear Manufacturer

Choosing the right wholesale swimwear manufacturer is a critical step in ensuring quality. Here are some tips to help you make the right choice.

Researching Potential Manufacturers

1. Online Directories and Trade Shows: Utilize online platforms and attend trade shows to find reputable manufacturers. Websites like Alibaba and Global Sources can be valuable resources.

2. Industry Reputation and Reviews: Look for manufacturers with positive reviews and a solid reputation in the industry. Testimonials from other brands can provide insights into their reliability.

Evaluating Manufacturer Capabilities

1. Production Capacity: Ensure the manufacturer can meet your production needs, especially during peak seasons.

2. Specialization in Swimwear: Choose manufacturers that specialize in swimwear to ensure they understand the unique requirements of the product.

3. Technology and Equipment Used: Advanced machinery can enhance production efficiency and quality. Inquire about the technology used in the manufacturing process.

Quality Assurance Practices

Quality assurance is vital when sourcing from wholesale swimwear manufacturers. Here are some practices to consider.

Importance of Quality Control (QC) Measures

Implementing robust QC measures can help identify defects before products reach the market. This includes regular inspections and testing throughout the production process.

Key QC Practices to Look For

1. Material Testing: Ensure that the manufacturer conducts tests for fabric durability, colorfastness, and resistance to chlorine and UV rays.

2. In-Process Inspections: Regular inspections during production can catch issues early, preventing costly mistakes.

3. Final Product Inspections: Before shipping, a final inspection should be conducted to ensure that all products meet quality standards.

Certifications and Standards to Consider

Look for manufacturers that adhere to industry standards and certifications, such as ISO and OEKO-TEX. These certifications indicate a commitment to quality and safety.

Communication and Collaboration

Effective communication is essential for a successful partnership with wholesale swimwear manufacturers.

Establishing Clear Communication Channels

Set up clear communication channels to discuss expectations, timelines, and any issues that may arise during production.

Importance of Detailed Specifications and Expectations

Provide detailed specifications for your swimwear, including design, materials, and quality standards. This clarity helps manufacturers understand your requirements.

Building a Collaborative Relationship with Manufacturers

Fostering a collaborative relationship can lead to better outcomes. Regular check-ins and feedback can help address issues promptly and improve the overall quality of the products.

Sampling and Prototyping

Requesting samples and prototypes is a crucial step in ensuring quality.

Importance of Requesting Samples Before Bulk Orders

Always request samples before placing a bulk order. This allows you to evaluate the quality, fit, and overall design of the swimwear.

Evaluating Samples for Quality and Fit

When evaluating samples, pay attention to the stitching, fabric feel, and overall construction. Ensure that the swimwear meets your quality standards.

Making Adjustments Based on Feedback

If the samples do not meet your expectations, provide feedback to the manufacturer. This collaboration can lead to improvements in the final product.

Logistics and Supply Chain Considerations

Understanding logistics and supply chain management is essential for ensuring timely delivery and quality.

Understanding Shipping and Handling Processes

Familiarize yourself with the shipping and handling processes to avoid delays and ensure that products arrive in good condition.

Importance of Timely Delivery and Inventory Management

Timely delivery is crucial for maintaining inventory levels and meeting customer demand. Work with manufacturers who have a proven track record of on-time delivery.

Strategies for Minimizing Risks in the Supply Chain

Implement strategies to minimize risks, such as diversifying suppliers and maintaining open communication throughout the supply chain.

Post-Production Quality Checks

Conducting quality checks after production is essential for maintaining high standards.

Conducting Inspections Upon Receipt of Goods

Inspect all shipments upon arrival to identify any defects or issues. This step is crucial for maintaining quality control.

Handling Defects and Returns

Have a clear process in place for handling defects and returns. This can help maintain customer satisfaction and protect your brand's reputation.

Continuous Improvement Feedback Loop

Establish a feedback loop with your manufacturers to continuously improve quality. Regular discussions about quality issues can lead to better practices and products.

Conclusion

Ensuring quality when sourcing from wholesale swimwear manufacturers is a multifaceted process that requires careful planning and execution. By understanding the manufacturing process, selecting the right manufacturer, implementing quality assurance practices, and maintaining effective communication, you can significantly enhance the quality of your swimwear products. Prioritizing quality not only protects your brand's reputation but also ensures customer satisfaction and loyalty.

Additional Resources

- Links to industry standards and guidelines

- Recommended reading on swimwear manufacturing and quality assurance

- Contact information for our factory for potential partnerships

Frequently Asked Questions

1. What should I look for in a wholesale swimwear manufacturer?

- Look for manufacturers with a good reputation, specialization in swimwear, and robust quality control measures.

2. How can I ensure the quality of swimwear samples?

- Evaluate the samples for fabric quality, stitching, and overall fit. Provide feedback to the manufacturer for adjustments.

3. What certifications should a swimwear manufacturer have?

- Look for certifications like ISO and OEKO-TEX, which indicate adherence to quality and safety standards.

4. How important is communication with manufacturers?

- Effective communication is crucial for setting expectations, addressing issues, and fostering a collaborative relationship.

5. What are the risks of sourcing from wholesale swimwear manufacturers?

- Risks include quality inconsistencies, shipping delays, and potential defects. Implementing quality control measures can help mitigate these risks.

By following these guidelines and best practices, you can ensure that your sourcing from wholesale swimwear manufacturers leads to high-quality products that meet your brand's standards and customer expectations.