Content Menu

● Understanding Acrylic Yarn

● Physical and Chemical Properties

● Mechanical Properties and Performance

● Suitability for Swimwear: A Detailed Analysis

● Practical Considerations and Performance in Use

● Alternative Materials: A Comprehensive Comparison

● Environmental Impact and Sustainability Considerations

● Market Trends and Future Developments

● Maintenance and Care Guidelines

● Drying and Storage Practices

● Practical Applications and Usage Scenarios

● Innovation and Future Perspectives

● Frequently Asked Questions

>> 1. Is acrylic yarn completely unsuitable for swimwear?

>> 2. How long can I expect acrylic swimwear to last?

>> 3. Can acrylic yarn be blended with other materials for better swimwear performance?

>> 4. What are the best alternatives to acrylic yarn for swimwear?

>> 5. How can I maximize the lifespan of acrylic swimwear?

● Conclusion

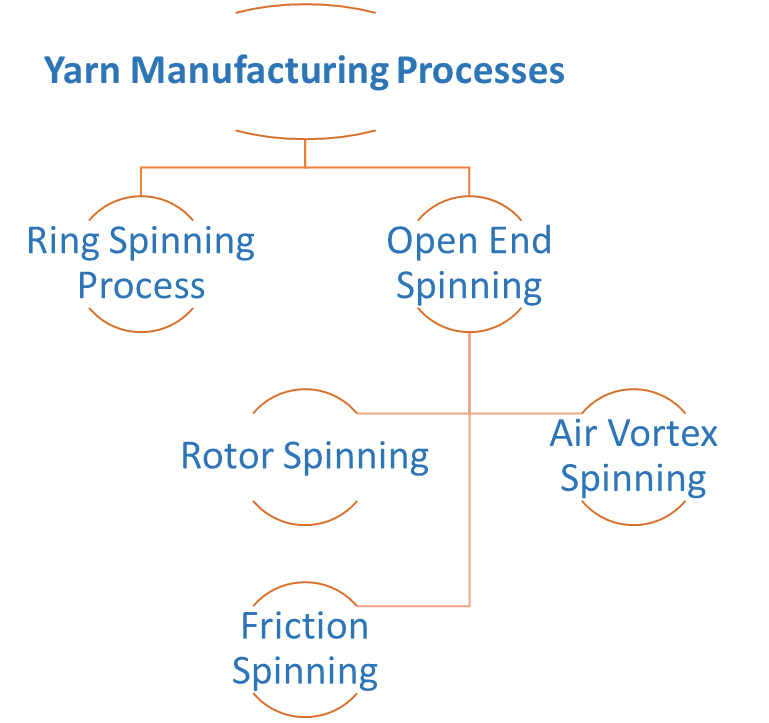

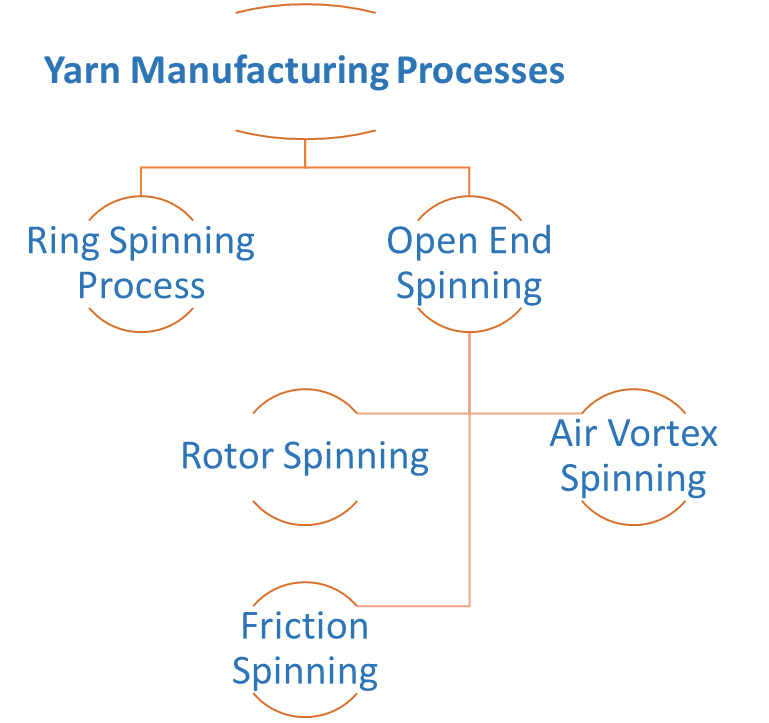

Understanding Acrylic Yarn

Acrylic yarn represents a remarkable achievement in synthetic fiber technology, emerging from the innovative minds of textile scientists in the mid-20th century. This versatile material begins its journey in petrochemical plants, where acrylonitrile, the primary building block, is carefully synthesized through a complex series of chemical reactions. The manufacturing process involves the polymerization of acrylonitrile monomers, creating long chains of molecules that give the fiber its distinctive properties. During production, manufacturers can fine-tune various parameters to achieve specific characteristics, such as fiber thickness, tensile strength, and surface texture.

The creation of acrylic fiber involves several sophisticated stages, beginning with the preparation of the polymer solution. This solution undergoes either wet or dry spinning processes, where it's extruded through tiny holes in a spinneret, forming continuous filaments. These filaments are then stretched and oriented to enhance their strength and durability. The resulting fibers undergo various treatments, including crimping and texturizing, which contribute to the yarn's final appearance and handle. Modern manufacturing techniques also incorporate special treatments to enhance properties like softness, static resistance, and color retention.

Physical and Chemical Properties

The physical properties of acrylic yarn make it a fascinating material to study in the context of swimwear applications. At its core, acrylic fiber possesses a unique molecular structure that gives it a density of approximately 1.17 g/cc, making it lighter than many natural fibers. The fiber diameter typically ranges from 10 to 40 micrometers, allowing for various yarn weights and textures. When examined under a microscope, acrylic fibers reveal either a round or kidney-shaped cross-section, which significantly influences how the yarn interacts with light and handles moisture. This structural characteristic contributes to the yarn's ability to maintain its shape and appearance even after repeated use.

In terms of moisture management, acrylic yarn demonstrates relatively low moisture regain, typically between 1.5% and 2% at standard atmospheric conditions. This property has both advantages and disadvantages for swimwear applications. While the low moisture absorption helps the fabric dry quickly after exposure to water, it can also lead to reduced comfort in hot conditions where perspiration management becomes crucial. The fiber's hydrophobic nature means that water tends to sit on the surface rather than being absorbed into the fiber structure, which can create a clammy feeling against the skin when wet.

Mechanical Properties and Performance

The mechanical properties of acrylic yarn play a crucial role in its performance as swimwear material. With a tensile strength ranging from 0.7 to 1.6 GPa, acrylic fibers demonstrate moderate durability, though they fall short of the strength exhibited by nylon or polyester. The yarn's elasticity, characterized by a modulus of 2.6-3.6 GPa, provides some flexibility but lacks the exceptional recovery properties needed for form-fitting swimwear. When stretched, acrylic fibers can extend 10-50% before breaking, but their recovery rate is notably lower than specialized elastomeric fibers commonly used in modern swimwear.

One of the most significant advantages of acrylic yarn lies in its chemical stability and resistance to environmental factors. The material shows excellent resistance to acids, making it suitable for use in chlorinated pool water. However, its sensitivity to alkaline solutions can pose problems in certain conditions. The fiber's outstanding light fastness ensures that swimwear maintains its color even after prolonged exposure to sunlight, a crucial factor for beachwear and outdoor swimming activities.

Suitability for Swimwear: A Detailed Analysis

When evaluating acrylic yarn's suitability for swimwear, we must consider multiple factors that affect both performance and user experience. The material's affordability makes it an attractive option for hobbyist crafters and small-scale producers. A standard skein of acrylic yarn typically costs 30-50% less than comparable quantities of specialized swimwear yarns, making it possible to experiment with designs without significant financial investment. This cost advantage has led to its popularity in the DIY swimwear community, particularly among beginners testing their skills in garment construction.

The color retention properties of acrylic yarn are particularly noteworthy in swimwear applications. Unlike natural fibers that may fade quickly with exposure to chlorine and sunlight, properly dyed acrylic yarns maintain their vibrancy through multiple swimming sessions. This resistance to fading is achieved through the fiber's ability to accept dyes deeply into its structure during manufacturing, creating a more permanent color bond. Additionally, the wide range of available colors allows designers and crafters to create visually striking swimwear pieces that maintain their aesthetic appeal throughout their lifespan.

Practical Considerations and Performance in Use

The real-world performance of acrylic yarn swimwear presents a complex set of considerations that merit careful examination. When submerged in water, acrylic yarn exhibits distinctive behavior that directly impacts the wearer's experience. Despite its synthetic nature, the material can absorb up to 2.5 times its weight in water, significantly more than specialized swimwear materials. This absorption leads to notable weight increase during use, which can cause the garment to sag and lose its intended shape. Additionally, the increased weight can create discomfort for the wearer, particularly during extended periods of water activity.

Temperature regulation becomes another crucial factor when considering acrylic yarn for swimwear. The material's inherent insulating properties, while beneficial in winter garments, can create uncomfortable heat retention during summer swimming activities. Unlike modern technical swimwear fabrics that actively wick moisture away from the body, acrylic yarn tends to create a barrier that traps heat and moisture against the skin. This characteristic can lead to overheating during active swimming or extended sun exposure, making it less suitable for intensive water sports or competitive swimming applications.

Alternative Materials: A Comprehensive Comparison

Nylon-based swimwear yarns have emerged as the industry standard, offering superior performance characteristics that directly address the limitations of acrylic alternatives. Modern nylon yarns incorporate advanced fiber technologies that provide exceptional stretch recovery, typically maintaining 95-98% of their original shape even after repeated use. These materials also feature specialized coatings that enhance chlorine resistance and UV protection, extending the garment's lifespan while protecting the wearer. The superior strength-to-weight ratio of nylon makes it possible to create lightweight, form-fitting swimwear that maintains its structural integrity even under demanding conditions.

Polyester-based swimming materials have also gained significant popularity, particularly in performance swimwear. These yarns typically feature modified cross-sections that enhance moisture wicking and reduce drag in the water. Advanced polyester formulations include antimicrobial treatments that prevent odor-causing bacteria growth, a significant advantage over traditional acrylic yarns. The material's exceptional dimensional stability ensures that swimwear maintains its fit and shape throughout its lifecycle, even with frequent exposure to chlorinated water and intense physical activity.

Environmental Impact and Sustainability Considerations

The environmental implications of acrylic yarn usage in swimwear extend far beyond the immediate concerns of performance and durability. As a petroleum-based product, acrylic fiber production contributes significantly to carbon emissions and environmental degradation. The manufacturing process requires substantial energy input and involves potentially harmful chemicals, raising important questions about sustainability. Recent studies have shown that a single production cycle of acrylic fiber can generate up to 30% more carbon emissions compared to natural fiber processing.

Microplastic pollution presents another significant environmental concern associated with acrylic swimwear. During each wash cycle, synthetic fibers shed microscopic particles that eventually make their way into water systems and marine environments. Research indicates that acrylic fibers may release up to 730,000 synthetic particles per wash, contributing to the growing global microplastic crisis. This environmental impact has led to increased scrutiny of synthetic materials in water-based applications and has sparked innovation in more sustainable alternatives.

Market Trends and Future Developments

The swimwear market continues to evolve rapidly, driven by changing consumer preferences and technological advancements. Recent market analysis indicates a growing demand for sustainable and performance-oriented swimwear materials, with consumers increasingly willing to invest in higher-quality alternatives to traditional acrylic options. This shift has prompted manufacturers to develop innovative hybrid materials that combine the cost-effectiveness of synthetic fibers with improved performance characteristics and reduced environmental impact.

Emerging technologies in fiber development are creating new possibilities for swimwear materials. Bio-based synthetic fibers, developed from renewable resources, are showing promise as sustainable alternatives to traditional petroleum-based materials. These innovations include modified cellulose fibers with enhanced water resistance and biodegradable synthetic polymers that maintain performance while reducing environmental impact. The integration of smart textile technologies is also opening new avenues for swimwear development, with materials that can adapt to environmental conditions and provide enhanced functionality.

Maintenance and Care Guidelines

The longevity and performance of swimwear made from acrylic yarn heavily depend on proper care and maintenance procedures. Unlike conventional clothing, swimwear faces unique challenges from exposure to chlorine, salt water, sunscreen, and other environmental factors. When caring for acrylic swimwear, it's essential to rinse the garment thoroughly in cool, fresh water immediately after each use. This immediate rinsing helps remove harmful chemicals and minerals that could otherwise degrade the fiber structure over time. Special attention should be paid to areas with high concentration of body oils or sunscreen, as these substances can become trapped within the fiber structure and lead to premature deterioration.

Machine washing acrylic swimwear requires specific considerations to maintain its integrity. The water temperature should never exceed 30°C (86°F), as higher temperatures can cause fiber distortion and permanent shape loss. Gentle cycle settings are mandatory, and the use of specialized swimwear detergents is highly recommended. These detergents are formulated to effectively remove chlorine and salt residues while preserving the fiber's structural integrity. Fabric softeners should be strictly avoided as they can create a coating that reduces the material's ability to shed water effectively and may trap harmful substances within the fibers.

Drying and Storage Practices

Proper drying techniques play a crucial role in maintaining the shape and durability of acrylic swimwear. Air drying in a shaded area is the optimal method, as direct sunlight can cause color fading and fiber degradation. The garment should be laid flat on a clean towel, gently reshaping it to maintain its original dimensions. Hanging wet swimwear can lead to stretching and distortion, particularly in areas bearing the weight of absorbed water. During the drying process, periodic repositioning helps ensure even drying and prevents water accumulation in specific areas.

Long-term storage requires careful attention to prevent damage and maintain the garment's quality. Before storage, ensure the swimwear is completely dry to prevent mildew growth and fiber deterioration. Store the garment in a cool, dry place away from direct sunlight and heat sources. Avoid folding the swimwear along the same lines repeatedly, as this can create permanent creases and weaken the fiber structure at fold points. Consider using acid-free tissue paper between folds to minimize creasing and maintain the garment's shape during extended storage periods.

Practical Applications and Usage Scenarios

While acrylic yarn presents certain limitations for competitive swimming applications, it finds its niche in specific recreational swimming scenarios. Beach cover-ups, casual poolside wear, and decorative swimming accessories represent appropriate applications where the material's properties can be advantageous. The yarn's excellent color retention and affordability make it particularly suitable for creating seasonal swimwear pieces that aren't intended for intensive use. Additionally, its quick-drying properties, though not matching specialized materials, prove adequate for casual water activities and brief swimming sessions.

For children's swimwear, acrylic yarn offers certain advantages in terms of cost-effectiveness and ease of care. The material's durability against regular washing and its ability to maintain bright colors appeal to parents looking for affordable swimming solutions. However, it's crucial to consider the intended use carefully, as active children might require more performance-oriented materials for regular swimming lessons or water sports activities. The material's weight when wet and potential for shape distortion should be carefully weighed against its benefits in these applications.

Innovation and Future Perspectives

The future of swimwear materials continues to evolve with technological advancements and changing consumer demands. Research and development efforts are focusing on creating hybrid fibers that combine the best properties of different materials while minimizing their drawbacks. Some promising developments include modified acrylic fibers with enhanced moisture-wicking capabilities and improved elasticity. These innovations aim to address the traditional limitations of acrylic yarn while maintaining its cost-effectiveness and ease of production.

Sustainable alternatives are also emerging as a response to environmental concerns. Bio-based synthetic fibers, recycled materials, and eco-friendly production methods are gaining traction in the swimwear industry. These developments suggest a future where performance, sustainability, and affordability can coexist in swimwear materials. While traditional acrylic yarn may see decreased usage in pure form, its principles and manufacturing techniques continue to influence the development of next-generation swimming materials.

Frequently Asked Questions

1. Is acrylic yarn completely unsuitable for swimwear?

Answer: While not ideal for performance swimwear, acrylic yarn can be suitable for casual swimming activities and beach accessories. Its limitations become more apparent in situations requiring high elasticity and shape retention.

2. How long can I expect acrylic swimwear to last?

Answer: With proper care and maintenance, acrylic swimwear can last one to two swimming seasons for casual use. However, frequent exposure to chlorine and intense use may significantly reduce its lifespan.

3. Can acrylic yarn be blended with other materials for better swimwear performance?

Answer: Yes, blending acrylic with materials like spandex or nylon can improve its performance characteristics, particularly in terms of elasticity and shape retention.

4. What are the best alternatives to acrylic yarn for swimwear?

Answer: Nylon, polyester, and specialized elastane blends are generally considered superior alternatives, offering better performance characteristics for dedicated swimwear.

5. How can I maximize the lifespan of acrylic swimwear?

Answer: Regular rinsing after use, proper washing techniques, avoiding direct sunlight during drying, and appropriate storage methods can significantly extend the life of acrylic swimwear.

Conclusion

After thorough analysis of acrylic yarn's properties, performance characteristics, and practical applications in swimwear, it becomes clear that while the material offers certain advantages in terms of cost and accessibility, it falls short of meeting the demanding requirements of performance swimwear. Its limitations in elasticity, weight when wet, and shape retention make it more suitable for casual water activities and decorative purposes rather than serious swimming applications.

The future of swimwear materials lies in the development of innovative solutions that balance performance, sustainability, and affordability. While acrylic yarn may continue to serve specific niches in the swimwear market, particularly in casual and decorative applications, the industry's direction is clearly moving toward specialized materials and sustainable alternatives that offer superior performance characteristics.

For consumers considering acrylic yarn for swimwear projects, it's essential to align expectations with the material's capabilities and intended use. Understanding its strengths and limitations allows for more informed decisions in selecting appropriate materials for specific swimming applications. As textile technology continues to advance, we can expect to see new materials and blends that better address the diverse needs of swimmers while maintaining environmental responsibility and economic accessibility.