Content Menu

● The Evolution of Ladies Swimwear Manufacturing

● The Design Process in Ladies Swimwear Manufacturing

● Material Selection and Innovation in Ladies Swimwear Manufacturing

● The Production Process in Ladies Swimwear Manufacturing

● Quality Control in Ladies Swimwear Manufacturing

● Sustainability Initiatives in Ladies Swimwear Manufacturing

● Marketing and Distribution in the Ladies Swimwear Manufacturing Industry

● Challenges and Opportunities in Ladies Swimwear Manufacturing

● Conclusion

Ladies swimwear manufacturers play a crucial role in the fashion industry, creating stylish and functional swimwear for women around the world. These manufacturers are at the forefront of innovation, constantly adapting to changing trends, consumer preferences, and technological advancements. In this comprehensive exploration of the ladies swimwear manufacturing industry, we'll delve into the various aspects that make this sector both challenging and exciting.

The Evolution of Ladies Swimwear Manufacturing

The history of ladies swimwear manufacturing is as fascinating as it is diverse. From the modest bathing gowns of the 19th century to the bold and revealing designs of today, the industry has undergone significant transformations. Ladies swimwear manufacturers have been at the forefront of these changes, adapting their production techniques and materials to meet evolving societal norms and fashion trends.

In the early days, ladies swimwear manufacturers focused on producing functional garments that allowed women to enjoy water activities while maintaining modesty. As societal attitudes shifted and women sought more freedom in their clothing choices, ladies swimwear manufacturers responded by creating more revealing and form-fitting designs. This evolution required manufacturers to develop new techniques for working with stretchy, water-resistant fabrics and to innovate in areas such as support and comfort.

Today, ladies swimwear manufacturers are faced with the challenge of balancing style, functionality, and sustainability. The modern consumer demands swimwear that not only looks good but also performs well in water, provides sun protection, and is environmentally friendly. This has led to a new era of innovation in the ladies swimwear manufacturing industry, with companies investing heavily in research and development to create cutting-edge products.

The Design Process in Ladies Swimwear Manufacturing

The creation of a new swimwear line begins long before any fabric is cut or sewn. Ladies swimwear manufacturers typically start the design process by conducting extensive market research to identify current trends, consumer preferences, and emerging styles. This research informs the creative direction for the upcoming season and helps manufacturers anticipate what styles will resonate with their target audience.

Once the research phase is complete, ladies swimwear manufacturers move on to the design stage. This is where creativity truly flourishes, as designers sketch out new concepts, experiment with different silhouettes, and select color palettes. Many ladies swimwear manufacturers employ teams of talented designers who work collaboratively to create cohesive collections that cater to a variety of body types and style preferences.

In recent years, technology has played an increasingly important role in the design process for ladies swimwear manufacturers. Computer-aided design (CAD) software allows designers to create detailed digital renderings of their swimwear concepts, which can be easily modified and refined. Some ladies swimwear manufacturers have even begun to use 3D modeling technology to visualize how their designs will look on different body types before moving to the prototype stage.

The importance of prototyping cannot be overstated in ladies swimwear manufacturing. Once designs are finalized on paper or in digital form, manufacturers create physical prototypes to test the fit, comfort, and functionality of their swimwear. This stage often involves multiple iterations as ladies swimwear manufacturers fine-tune their designs based on feedback from fit models and internal testing.

Material Selection and Innovation in Ladies Swimwear Manufacturing

One of the most critical aspects of ladies swimwear manufacturing is the selection of appropriate materials. The fabrics used in swimwear must be able to withstand exposure to chlorine, saltwater, and sunlight while remaining comfortable and retaining their shape. Ladies swimwear manufacturers invest significant resources in sourcing and developing fabrics that meet these demanding requirements.

Traditionally, ladies swimwear manufacturers have relied heavily on synthetic materials such as nylon and spandex for their products. These materials offer excellent stretch, quick-drying properties, and durability. However, as consumers become more environmentally conscious, many ladies swimwear manufacturers are exploring alternative, sustainable materials.

Recycled polyester, made from post-consumer plastic bottles, has gained popularity among eco-friendly ladies swimwear manufacturers. This material offers similar performance characteristics to traditional polyester but with a significantly reduced environmental impact. Some innovative ladies swimwear manufacturers are even experimenting with biodegradable fabrics derived from natural sources such as algae or plant-based materials.

In addition to the main fabric, ladies swimwear manufacturers must also consider lining materials, trims, and embellishments. These components play a crucial role in the overall quality and appearance of the finished product. Many ladies swimwear manufacturers opt for quick-drying, antimicrobial linings to enhance comfort and hygiene, while carefully selecting hardware and decorative elements that can withstand exposure to water and sun.

The Production Process in Ladies Swimwear Manufacturing

Once the design is finalized and materials are selected, ladies swimwear manufacturers move on to the production phase. This process typically involves several stages, each requiring specialized skills and equipment.

Cutting is the first step in the production process for ladies swimwear manufacturers. Fabric is laid out in multiple layers, and pattern pieces are cut using either manual techniques or computer-controlled cutting machines. Precision is crucial at this stage, as even small errors can result in ill-fitting garments.

After cutting, the various pieces of the swimsuit are assembled by skilled sewers. Ladies swimwear manufacturers often use specialized sewing machines designed to handle stretchy fabrics and create strong, flexible seams. The construction of swimwear requires a high level of expertise, as the garments must be able to withstand the stress of wear in water while maintaining their shape and support.

Many ladies swimwear manufacturers incorporate additional features into their products during the sewing process. This may include adding padding or underwire for support, inserting adjustable straps, or incorporating decorative elements such as ruching or cut-outs. These details can significantly enhance the functionality and aesthetic appeal of the swimwear.

Once the main construction is complete, ladies swimwear manufacturers move on to the finishing stages. This often involves adding labels, attaching hardware such as clasps or adjusters, and performing a final quality check. Some ladies swimwear manufacturers also incorporate post-production treatments, such as applying water-repellent coatings or UV-protective finishes, to enhance the performance of their products.

Quality Control in Ladies Swimwear Manufacturing

Quality control is a critical aspect of ladies swimwear manufacturing. Given the demanding conditions in which swimwear is worn, even small defects can lead to customer dissatisfaction or product failure. As a result, ladies swimwear manufacturers typically implement rigorous quality control measures throughout the production process.

These measures often begin with thorough testing of raw materials to ensure they meet the required specifications for strength, stretch, and colorfastness. During production, ladies swimwear manufacturers may conduct regular inspections to catch any issues early in the process. This can include checking seam strength, evaluating the accuracy of cuts, and assessing the overall construction quality.

After production, many ladies swimwear manufacturers subject their products to a series of tests designed to simulate real-world use. This may include stretch and recovery tests, chlorine resistance evaluations, and assessments of how the swimwear performs when wet. Some ladies swimwear manufacturers even conduct wear tests, having individuals use the products in actual swimming conditions to gather feedback on comfort, fit, and durability.

Sustainability Initiatives in Ladies Swimwear Manufacturing

As environmental concerns become increasingly prominent, many ladies swimwear manufacturers are taking steps to reduce their ecological footprint. This shift towards sustainability is driven both by consumer demand and a growing awareness within the industry of the need for more responsible production practices.

One area where ladies swimwear manufacturers are making significant strides is in the use of recycled and eco-friendly materials. As mentioned earlier, recycled polyester is becoming increasingly common in swimwear production. Some ladies swimwear manufacturers are going even further, exploring innovative materials such as fabrics made from reclaimed fishing nets or regenerated nylon fibers.

Water conservation is another focus area for environmentally conscious ladies swimwear manufacturers. Traditional textile dyeing and finishing processes can be water-intensive, so some manufacturers are investing in technologies that reduce water usage or allow for water recycling. Digital printing techniques, which require less water than conventional methods, are also gaining popularity among ladies swimwear manufacturers.

Waste reduction is a key concern for many ladies swimwear manufacturers. Some companies are implementing zero-waste design principles, creating patterns that maximize fabric utilization and minimize scraps. Others are exploring ways to recycle or repurpose production waste, such as turning fabric offcuts into accessories or packaging materials.

Marketing and Distribution in the Ladies Swimwear Manufacturing Industry

While the production of high-quality swimwear is crucial, ladies swimwear manufacturers must also navigate the complexities of marketing and distribution to succeed in this competitive industry. Many manufacturers work closely with retailers, both brick-and-mortar stores and online platforms, to get their products in front of consumers.

Some ladies swimwear manufacturers opt to create their own branded lines, which requires a more comprehensive marketing approach. This may involve developing a strong brand identity, creating engaging content for social media and other digital platforms, and potentially opening branded retail locations or e-commerce sites.

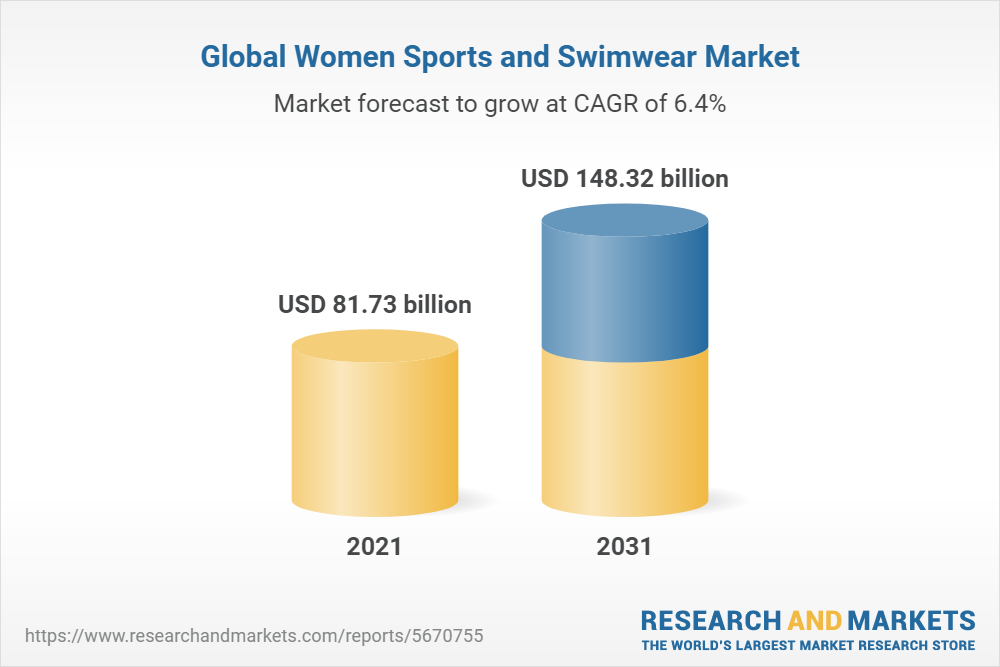

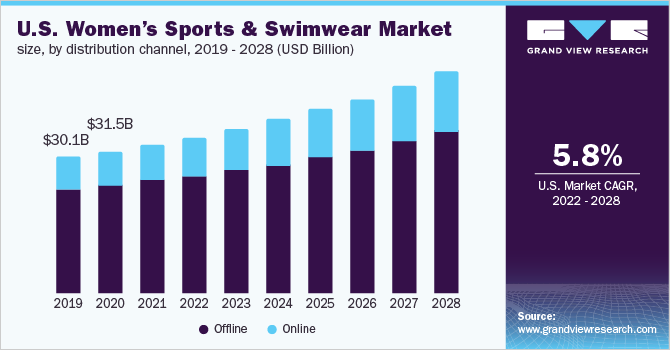

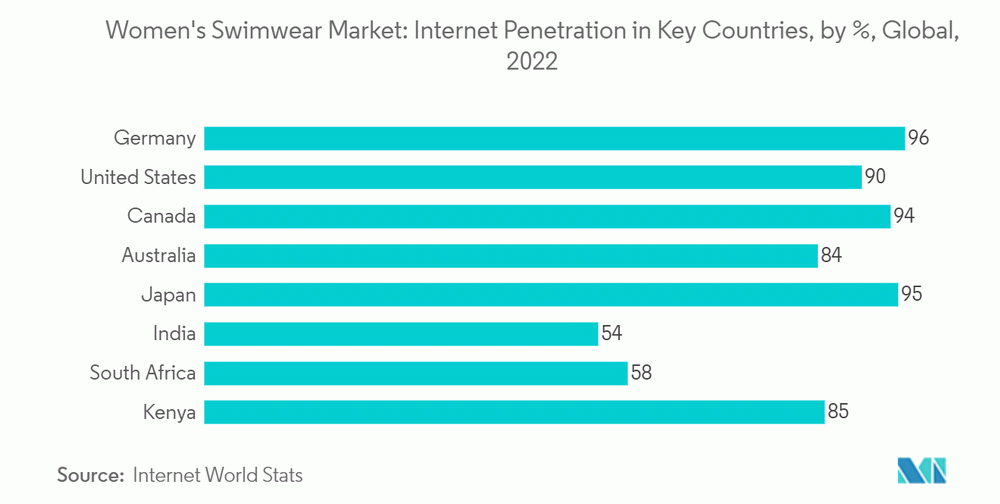

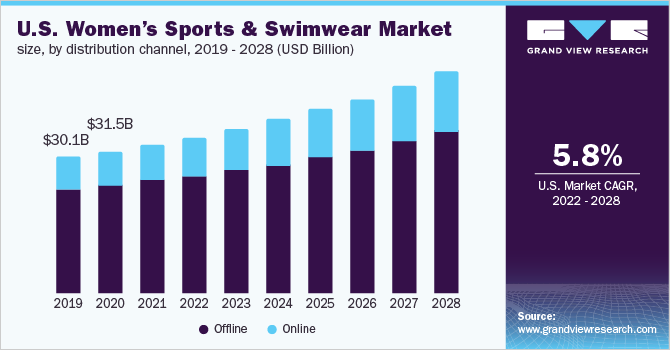

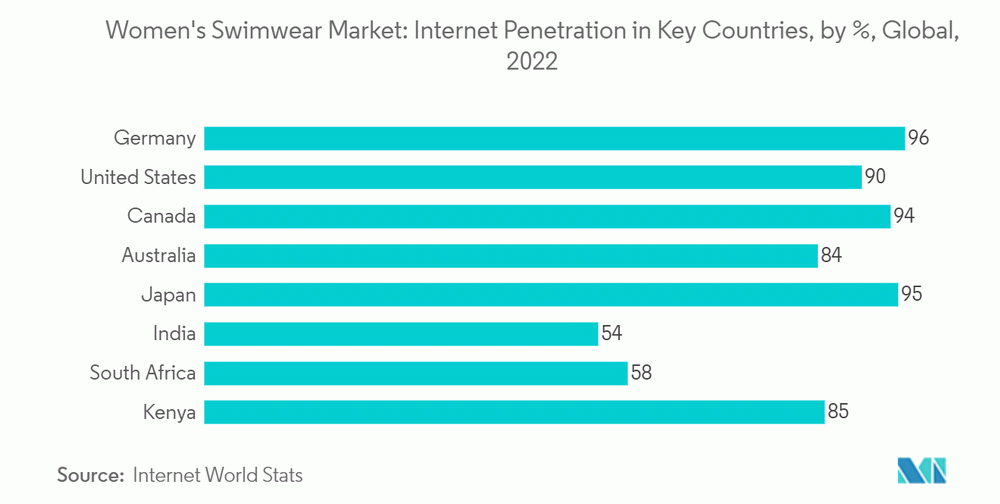

The rise of e-commerce has had a significant impact on the ladies swimwear manufacturing industry. Online sales of swimwear have grown rapidly in recent years, presenting both opportunities and challenges for manufacturers. While e-commerce allows ladies swimwear manufacturers to reach a global audience, it also requires them to adapt their products and marketing strategies to suit the online shopping experience.

Many ladies swimwear manufacturers are embracing technology to enhance their marketing efforts. Virtual try-on tools, which use augmented reality to show customers how swimwear might look on their body type, are becoming increasingly popular. Some manufacturers are also leveraging artificial intelligence to provide personalized product recommendations based on customer preferences and body measurements.

Challenges and Opportunities in Ladies Swimwear Manufacturing

The ladies swimwear manufacturing industry faces several challenges as it continues to evolve. One of the most significant is the increasing pressure to produce swimwear quickly and at low cost to meet the demands of fast fashion. This can lead to compromises in quality and working conditions, issues that responsible ladies swimwear manufacturers must navigate carefully.

Another challenge is the seasonality of the swimwear market in many regions. Ladies swimwear manufacturers often face feast-or-famine cycles, with intense production periods followed by lulls. Some manufacturers are addressing this by diversifying their product lines to include related items such as activewear or resort wear, or by targeting markets in different hemispheres to balance their production schedules.

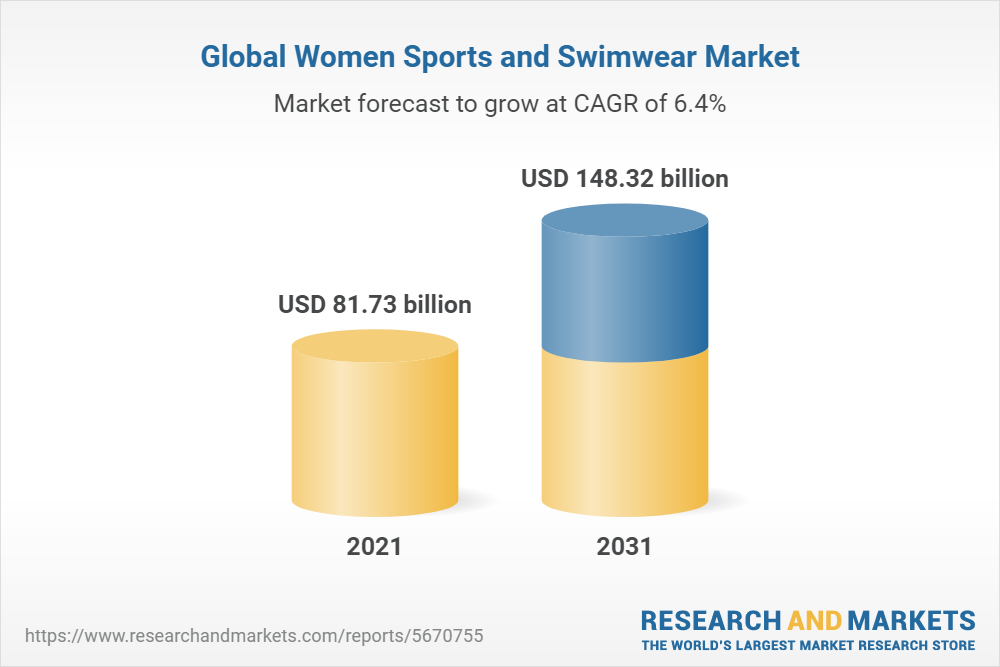

Despite these challenges, the ladies swimwear manufacturing industry also presents numerous opportunities. The growing focus on body positivity and inclusivity has opened up new markets for manufacturers who can provide stylish, well-fitting swimwear for a diverse range of body types. Similarly, the increasing popularity of swimming as a form of exercise has created demand for performance-oriented swimwear, presenting opportunities for innovation in design and materials.

The future of ladies swimwear manufacturing is likely to be shaped by continued technological advancements. From 3D-printed swimwear to smart fabrics that can change color or provide UV protection, the possibilities for innovation are vast. Ladies swimwear manufacturers who can successfully integrate these technologies into their products while maintaining a focus on style and comfort are likely to thrive in the coming years.

Conclusion

The world of ladies swimwear manufacturing is a dynamic and multifaceted industry that combines creativity, technical expertise, and business acumen. From the initial design concept to the final product on store shelves, ladies swimwear manufacturers navigate a complex process that requires attention to detail, innovation, and adaptability.

As consumer preferences continue to evolve and new technologies emerge, ladies swimwear manufacturers will need to stay agile and forward-thinking. Those who can balance style, functionality, sustainability, and affordability while meeting the diverse needs of their customers are likely to find success in this competitive industry.

Whether you're a fashion enthusiast, an aspiring designer, or simply someone who appreciates the artistry and engineering that goes into creating the perfect swimsuit, the world of ladies swimwear manufacturing offers a fascinating glimpse into the intersection of fashion, technology, and business. As we look to the future, it's clear that ladies swimwear manufacturers will continue to play a crucial role in shaping how we enjoy our time in and around the water, one stylish swimsuit at a time.