Content Menu

● Introduction

● Current Trends in the Swimwear Market

● Use of Sustainable Materials

● Technological Innovations

● Personalization and Customization Services

● Design Trends

● Opportunities and Challenges in the Global Market

● Conclusion

● Frequently Asked Questions

>> 1. What are OEM swimwear manufacturers?

>> 2. How can OEM swimwear manufacturers ensure sustainability in their products?

>> 3. What role does technology play in OEM swimwear manufacturing?

>> 4. Why is customization important in the swimwear market?

>> 5. What are the current design trends in swimwear?

Introduction

In recent years, the swimwear industry has experienced significant transformations, driven by changing consumer preferences, technological advancements, and a growing emphasis on sustainability. As OEM swimwear manufacturers, understanding these trends is crucial for staying competitive in a rapidly evolving market. This article explores the latest trends in OEM swimwear manufacturing, highlighting the importance of innovation, sustainability, and customization in meeting the demands of global consumers.

Current Trends in the Swimwear Market

The swimwear market has seen a shift in consumer preferences, with an increasing focus on functionality, style, and sustainability. Today's consumers are not only looking for fashionable swimwear but also for products that align with their values. This shift has led to a rise in demand for high-quality, durable, and eco-friendly swimwear options. OEM swimwear manufacturers must adapt to these changing preferences by offering products that meet the evolving needs of their clients.

One notable trend is the growing popularity of athleisure swimwear, which combines the functionality of athletic wear with the aesthetics of traditional swimwear. This trend reflects a broader movement towards versatile clothing that can be worn in various settings, from the beach to the gym. OEM swimwear manufacturers are responding by creating designs that cater to this demand, incorporating features such as quick-drying fabrics, UV protection, and stylish cuts.

Use of Sustainable Materials

Sustainability has become a key focus for OEM swimwear manufacturers as consumers increasingly prioritize eco-friendly products. The use of sustainable materials, such as recycled polyester and nylon, is on the rise. These materials not only reduce environmental impact but also appeal to consumers who are conscious of their purchasing decisions.

Recycled polyester, made from post-consumer plastic bottles, is gaining traction in the swimwear industry. It offers the same quality and durability as traditional polyester while significantly reducing waste. Additionally, some OEM swimwear manufacturers are exploring innovative materials, such as biodegradable fabrics and organic cotton, to further enhance their sustainability efforts.

By incorporating sustainable materials into their production processes, OEM swimwear manufacturers can differentiate themselves in a crowded market. This commitment to sustainability not only attracts environmentally conscious consumers but also aligns with global efforts to reduce plastic waste and promote responsible manufacturing practices.

Technological Innovations

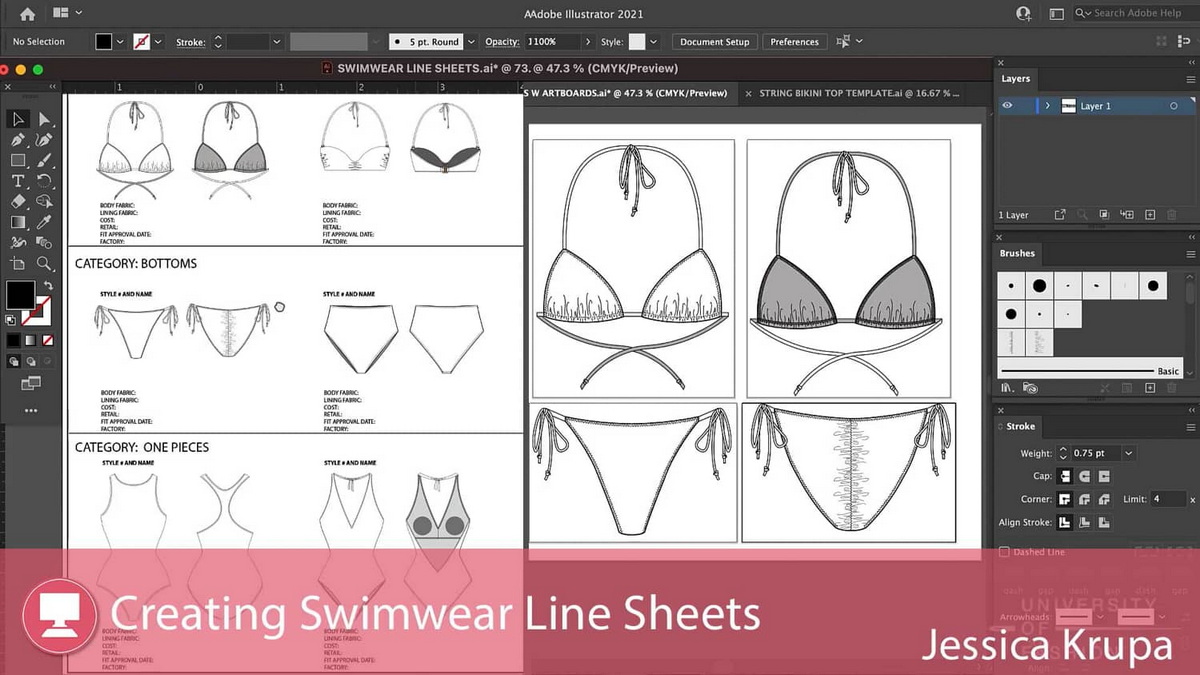

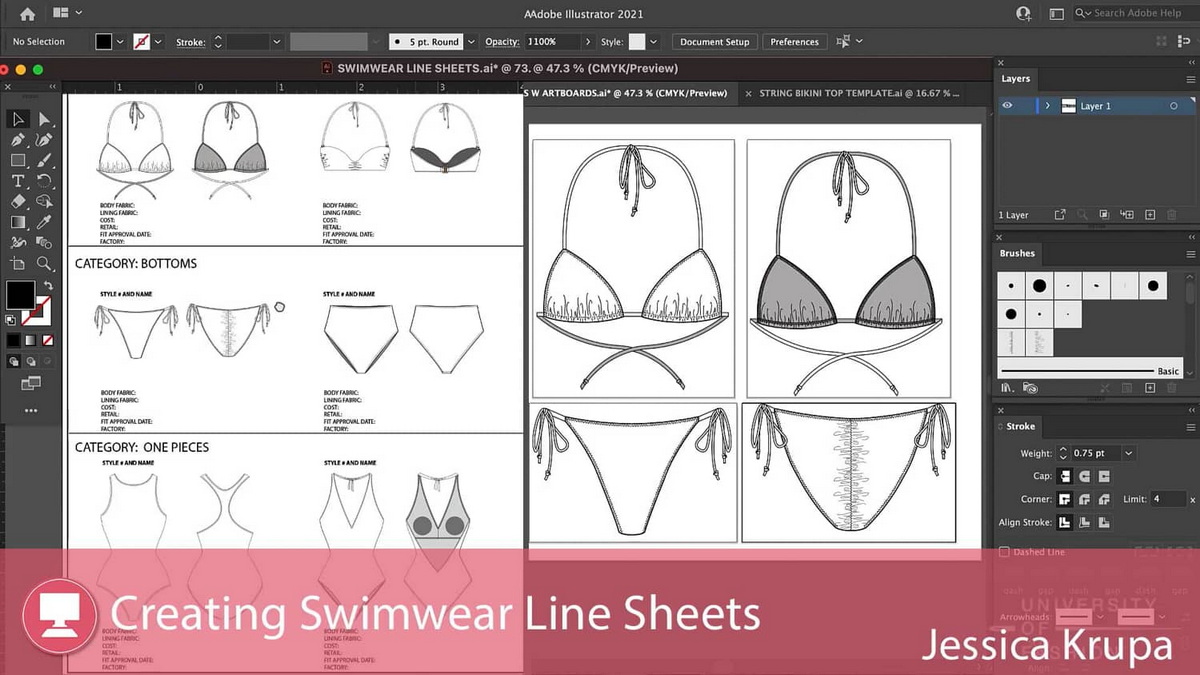

Technological advancements are reshaping the landscape of OEM swimwear manufacturing. Innovations such as 3D printing and smart manufacturing are revolutionizing the way swimwear is designed and produced. These technologies enable manufacturers to create customized products more efficiently and with greater precision.

3D printing, for instance, allows OEM swimwear manufacturers to produce prototypes quickly, reducing the time and cost associated with traditional manufacturing methods. This technology also enables the creation of intricate designs that may be difficult to achieve through conventional means. As a result, manufacturers can respond more rapidly to market trends and consumer demands.

Smart manufacturing, which involves the integration of advanced technologies such as the Internet of Things (IoT) and artificial intelligence (AI), is also transforming the swimwear production process. By leveraging data analytics and automation, OEM swimwear manufacturers can optimize their operations, improve quality control, and enhance supply chain management. This not only increases efficiency but also reduces waste and lowers production costs.

Personalization and Customization Services

As consumers seek unique and personalized products, OEM swimwear manufacturers are increasingly offering customization services. This trend reflects a broader shift towards individualized shopping experiences, where consumers want to express their personal style through their swimwear choices.

Customization options can range from selecting colors and patterns to adding personalized logos or names. By providing these services, OEM swimwear manufacturers can cater to niche markets, such as swim teams, resorts, and fitness clubs, which often require branded swimwear for their members.

Moreover, the rise of online shopping has made it easier for consumers to access personalized swimwear options. Many OEM swimwear manufacturers are now leveraging e-commerce platforms to offer customization tools that allow customers to design their swimwear from the comfort of their homes. This not only enhances customer satisfaction but also fosters brand loyalty.

Design Trends

The design of swimwear is continually evolving, influenced by fashion trends, cultural shifts, and consumer preferences. OEM swimwear manufacturers must stay attuned to these changes to create products that resonate with their target audience.

Currently, bold colors, vibrant patterns, and unique cuts are dominating the swimwear landscape. From high-waisted bikinis to one-piece swimsuits with cutouts, consumers are looking for styles that make a statement. Additionally, the use of innovative prints, such as tropical motifs and geometric designs, is gaining popularity.

Another significant trend is the incorporation of functional elements into swimwear design. Features such as adjustable straps, built-in support, and quick-drying fabrics are becoming standard as consumers prioritize comfort and practicality. OEM swimwear manufacturers that can blend style with functionality will have a competitive edge in the market.

Opportunities and Challenges in the Global Market

The global swimwear market presents both opportunities and challenges for OEM swimwear manufacturers. As the demand for swimwear continues to grow, particularly in emerging markets, manufacturers have the chance to expand their reach and tap into new customer segments.

However, navigating the complexities of international trade can be challenging. OEM swimwear manufacturers must be aware of varying regulations, tariffs, and cultural preferences in different regions. Additionally, competition from both established brands and new entrants can make it difficult to maintain market share.

To succeed in the global market, OEM swimwear manufacturers should focus on building strong relationships with their clients, investing in marketing strategies that resonate with local consumers, and continuously innovating their product offerings. By staying agile and responsive to market changes, manufacturers can capitalize on emerging opportunities while mitigating potential risks.

Conclusion

The landscape of OEM swimwear manufacturing is evolving rapidly, driven by changing consumer preferences, technological advancements, and a growing emphasis on sustainability. By embracing these trends, OEM swimwear manufacturers can position themselves for success in a competitive market. From utilizing sustainable materials to offering personalized services and incorporating innovative designs, the future of swimwear manufacturing is bright for those willing to adapt and innovate.

As the industry continues to evolve, staying informed about the latest trends and consumer demands will be essential for OEM swimwear manufacturers. By prioritizing sustainability, embracing technology, and focusing on customization, manufacturers can not only meet the needs of their clients but also contribute to a more sustainable and responsible swimwear industry.

Frequently Asked Questions

1. What are OEM swimwear manufacturers?

OEM swimwear manufacturers are companies that produce swimwear products for other brands under their specifications. They provide manufacturing services, allowing brands to focus on design and marketing.

2. How can OEM swimwear manufacturers ensure sustainability in their products?

OEM swimwear manufacturers can ensure sustainability by using eco-friendly materials, implementing waste-reduction practices, and adopting sustainable manufacturing processes.

3. What role does technology play in OEM swimwear manufacturing?

Technology plays a crucial role in OEM swimwear manufacturing by enabling efficient production processes, enhancing design capabilities through 3D printing, and improving supply chain management through smart manufacturing.

4. Why is customization important in the swimwear market?

Customization is important because it allows consumers to express their personal style and preferences, leading to increased customer satisfaction and brand loyalty.

5. What are the current design trends in swimwear?

Current design trends in swimwear include bold colors, unique patterns, functional elements, and styles that combine fashion with practicality, such as high-waisted bikinis and one-piece swimsuits with cutouts.