Content Menu

● Manufacturer Qualifications and Certifications

● Production Capacity and Technical Expertise

● Product Quality Control

● Design and Innovation Capabilities

● Client Cases and Market Reputation

● Pricing and Cost-Effectiveness

● Geographical Location and Logistics Capabilities

● Conclusion and Recommendations

● Frequently Asked Questions

>> 1. What certifications should I look for in a swimwear manufacturer?

>> 2. How can I assess a manufacturer's production capacity?

>> 3. What quality control processes should a swimwear manufacturer have?

>> 4. How important is design capability in a swimwear manufacturer?

>> 5. What factors influence the pricing of swimwear manufacturing?

The swimwear industry is a vibrant and competitive market, with numerous brands vying for consumer attention. As a swimwear brand, wholesaler, or manufacturer, selecting the right manufacturing partner is crucial for your success. The quality of your products, the efficiency of your supply chain, and ultimately, your brand's reputation depend significantly on the capabilities of your swimwear manufacturer. This article will explore how to identify the best swimwear manufacturers, focusing on key factors that distinguish the top players in the industry.

Manufacturer Qualifications and Certifications

When evaluating swimwear manufacturers, one of the first aspects to consider is their qualifications and certifications. The best swimwear manufacturers often hold various industry certifications that demonstrate their commitment to quality and compliance with international standards.

ISO certifications are among the most recognized qualifications in manufacturing. An ISO 9001 certification indicates that a manufacturer has established a quality management system that meets international standards. This certification ensures that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, certifications related to environmental management (ISO 14001) and occupational health and safety (ISO 45001) can also be indicators of a responsible and forward-thinking manufacturer.

Beyond ISO certifications, look for manufacturers that have certifications specific to the textile and apparel industry. For instance, certifications from organizations like OEKO-TEX® or GOTS (Global Organic Textile Standard) can indicate that the manufacturer adheres to strict environmental and safety standards, which is increasingly important to consumers today.

Production Capacity and Technical Expertise

Another critical factor in determining the best swimwear manufacturers is their production capacity and technical expertise. A manufacturer's ability to meet your production demands is essential, especially during peak seasons when demand for swimwear surges.

Assessing the modernization of a manufacturer's production equipment is vital. The best swimwear manufacturers invest in state-of-the-art machinery that enhances efficiency and product quality. Advanced sewing machines, cutting-edge fabric printing technology, and automated quality control systems can significantly impact the final product's quality and consistency.

Moreover, the technical expertise of the manufacturer's team plays a crucial role in the production process. A skilled workforce with experience in swimwear production can navigate the complexities of fabric types, stitching techniques, and design specifications. Manufacturers that prioritize training and development for their employees are more likely to produce high-quality swimwear that meets your brand's standards.

Product Quality Control

Quality control is a non-negotiable aspect of swimwear manufacturing. The best swimwear manufacturers implement rigorous quality control processes to ensure that every piece of swimwear meets the highest standards before it reaches the market.

A comprehensive quality inspection process typically includes multiple stages, from raw material inspection to final product testing. Manufacturers should have protocols in place to check for defects in fabric, stitching, and overall construction. Additionally, they should conduct wear tests to ensure that the swimwear performs well in real-world conditions, such as resistance to chlorine and UV rays.

Customer feedback is another critical component of quality control. The best swimwear manufacturers actively seek feedback from their clients and end-users to identify areas for improvement. A responsive manufacturer that values customer input is more likely to produce swimwear that aligns with market demands and consumer preferences.

Design and Innovation Capabilities

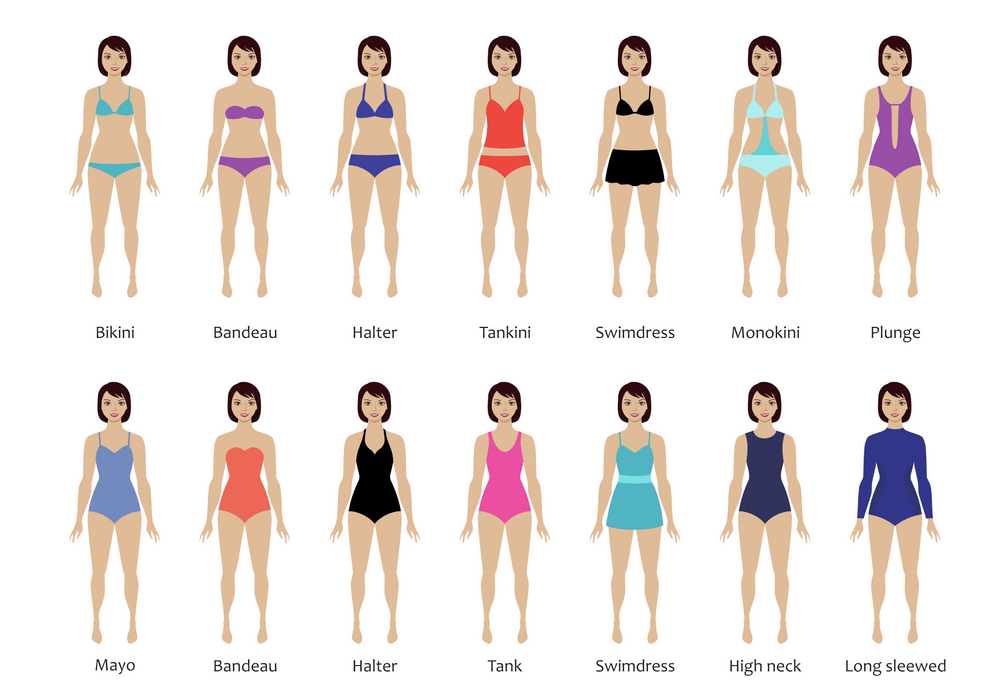

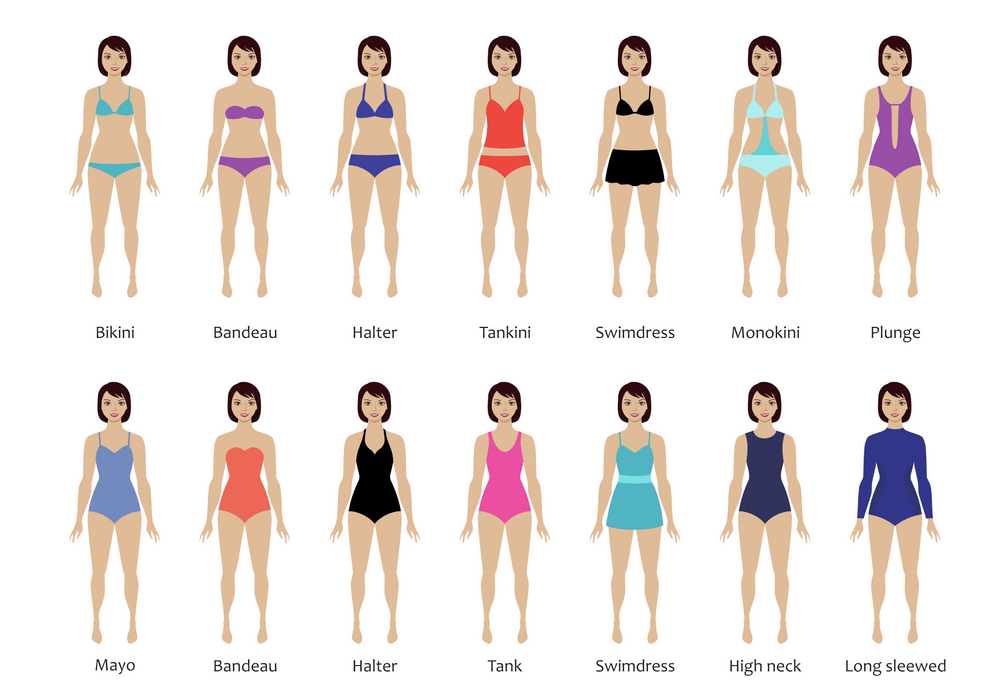

In the fashion industry, design and innovation are key differentiators. The best swimwear manufacturers not only produce high-quality products but also have strong design capabilities that can help brands stand out in a crowded market.

A manufacturer with a talented design team can assist in creating unique swimwear styles that resonate with consumers. This includes understanding current trends, fabric innovations, and consumer preferences. The ability to collaborate with designers and provide input on feasibility and production techniques is a significant advantage.

Furthermore, the speed at which a manufacturer can develop new products is crucial. The best swimwear manufacturers have streamlined processes for new product development, allowing brands to bring their designs to market quickly. This agility is essential in an industry where trends can change rapidly, and timely product launches can make a significant difference in sales.

Client Cases and Market Reputation

Examining a manufacturer's client cases and market reputation can provide valuable insights into their capabilities and reliability. The best swimwear manufacturers often have a portfolio of successful collaborations with well-known brands, which can serve as a testament to their quality and service.

Look for case studies or testimonials from previous clients that highlight the manufacturer's strengths. Positive feedback regarding product quality, communication, and delivery timelines can indicate a manufacturer's reliability. Additionally, a strong presence in industry trade shows and events can reflect a manufacturer's commitment to staying relevant and connected within the swimwear market.

Reputation can also be gauged through online reviews and industry publications. Engaging with other brands and industry professionals can provide firsthand accounts of their experiences with specific manufacturers, helping you make an informed decision.

Pricing and Cost-Effectiveness

While quality is paramount, pricing is also a critical factor when selecting a swimwear manufacturer. The best swimwear manufacturers offer competitive pricing without compromising on quality. It's essential to understand the pricing structure and what factors contribute to the overall cost of production.

Transparency in pricing is crucial. A reputable manufacturer should provide a clear breakdown of costs, including materials, labor, and any additional fees. This transparency allows brands to assess the cost-effectiveness of their manufacturing partner.

Evaluating cost-effectiveness goes beyond just the initial price. Consider the long-term value a manufacturer can provide. A slightly higher upfront cost may be justified if the manufacturer consistently delivers high-quality products that reduce returns and enhance customer satisfaction.

Geographical Location and Logistics Capabilities

The geographical location of a swimwear manufacturer can significantly impact logistics and shipping costs. The best swimwear manufacturers are strategically located to facilitate efficient distribution channels. Proximity to major shipping ports or transportation hubs can reduce lead times and shipping expenses, which is particularly important for brands that operate on tight schedules.

Additionally, a manufacturer's logistics management capabilities are crucial. Efficient logistics can streamline the supply chain, ensuring that products are delivered on time and in good condition. Manufacturers that utilize advanced logistics software and have established relationships with reliable shipping partners can enhance the overall efficiency of the production process.

Conclusion and Recommendations

Identifying the best swimwear manufacturers requires careful consideration of various factors, including qualifications, production capacity, quality control, design capabilities, reputation, pricing, and logistics. By thoroughly evaluating potential manufacturing partners against these criteria, brands can make informed decisions that align with their business goals.

When seeking a swimwear manufacturer, prioritize those that demonstrate a commitment to quality, innovation, and customer satisfaction. Building a strong partnership with a reputable manufacturer can lead to long-term success in the competitive swimwear market.

Frequently Asked Questions

1. What certifications should I look for in a swimwear manufacturer?

Look for ISO certifications, OEKO-TEX®, and GOTS certifications, which indicate quality management and adherence to environmental standards.

2. How can I assess a manufacturer's production capacity?

Inquire about their machinery, workforce size, and past production volumes to gauge their ability to meet your demands.

3. What quality control processes should a swimwear manufacturer have?

A good manufacturer should have multiple inspection stages, including raw material checks, in-process inspections, and final product testing.

4. How important is design capability in a swimwear manufacturer?

Design capability is crucial as it allows for the creation of unique and trendy swimwear that can differentiate your brand in the market.

5. What factors influence the pricing of swimwear manufacturing?

Pricing is influenced by material costs, labor, production volume, and the manufacturer's overhead. Transparency in pricing is essential for evaluating cost-effectiveness.