Content Menu

● The Manufacturing Process

>> Designing the Swimwear

>> Choosing the Fabric

>> Cutting and Sewing

>> Adding Details

● Managing Production Costs

>> Buying Materials in Bulk

>> Efficient Workflows

>> Using Machines

● Supply Chain Management

>> Sourcing Materials

>> Shipping and Delivery

>> Inventory Management

● Quality Control

>> Inspecting the Swimwear

>> Testing the Materials

>> Making Improvements

● Conclusion

● Frequently Asked Questions (FAQs)

>> Why is swimwear made in China?

>> How do factories keep production costs low?

>> What quality checks are done on swimwear?

Discover the hidden secrets of the top swimwear factories in China and how they can revolutionize your swimwear business.

Have you ever wondered how the colorful swimwear you see in stores is made? In this article, we are going to learn about how swimwear is made in factories in China. Many people choose to produce swimwear in these factories because they have a special way of working. This includes the manufacturing process, which is like a recipe that guides workers through each step of making swimwear.

We will talk about the steps involved in making swimwear, how the costs are managed in a smart way, and why it’s important to check the quality of the swimwear. Understanding these things helps us appreciate the effort that goes into creating the fun and stylish swimwear we love to wear at the beach or pool. So, let’s dive right in and explore the fascinating world of swimwear factories in China!

The Manufacturing Process

In a swimwear factory in China, the manufacturing process is a fun and fascinating journey that involves several important steps. Let’s explore how swimwear is made, from the very beginning to the finished product!

Designing the Swimwear

Everything starts with the designers. They create the first drawings and plans for the swimwear. Designers think about the colors, styles, and patterns that will look great and be popular. They make sure the designs are not only pretty but also practical for swimming. Once the designs are ready, they move on to the next step of the process.

Choosing the Fabric

After the swimwear is designed, the factories need to choose the right fabric. This is really important because the fabric needs to be comfortable and durable. Workers look for materials that can stretch, dry quickly, and feel nice on the skin. Sometimes, designers work with fabric experts to pick the best choices that fit the swimwear’s design and purpose.

Cutting and Sewing

Next comes the exciting part: cutting and sewing! The chosen fabric is laid out flat, and special machines or scissors are used to cut it into the right shapes and sizes. Then, skilled workers sew the pieces together. This is where the swimwear starts to take shape! They must follow the design carefully to make sure everything fits together perfectly.

Adding Details

Once the main swimwear is sewn together, it’s time to add the finishing touches. This includes putting on zippers, straps, and buttons. These details can make the swimwear even more stylish and functional. The workers pay close attention to how everything is placed, ensuring it looks great and works well for everyone who will wear it.

Throughout this manufacturing process, factories in China focus on quality and efficiency, making sure that every piece of swimwear is made carefully and with attention to detail. This way, swimmers can enjoy their time in the pool or at the beach with confidence!

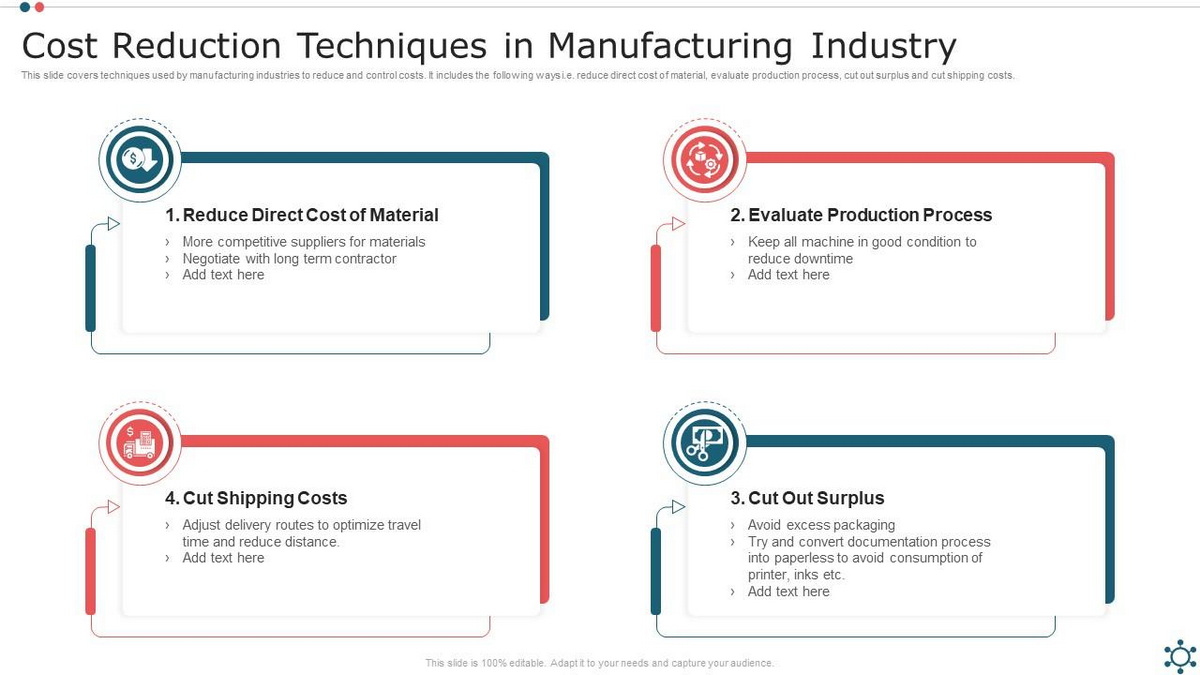

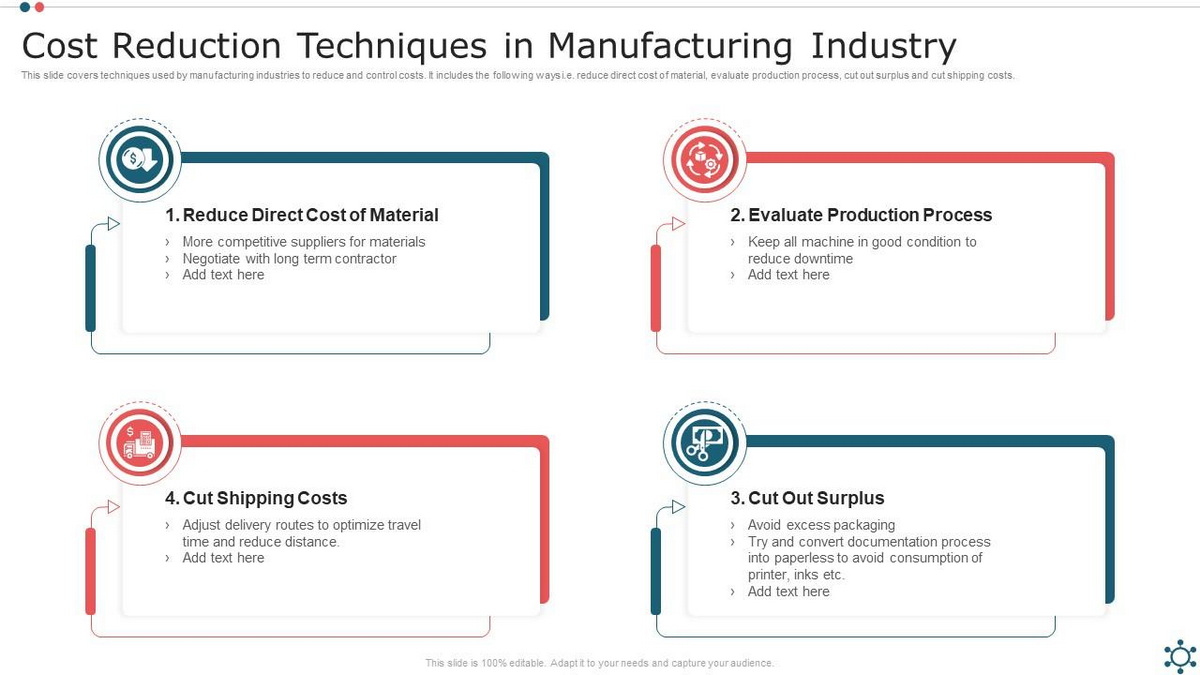

Managing Production Costs

When a swimwear factory in China makes swimsuits, it’s important to keep production costs low. This way, they can sell the swimwear at a good price and still make money. Let's explore some smart ways factories manage these costs to stay cost-effective.

Buying Materials in Bulk

One way factories save money is by buying materials in big amounts. When they purchase fabric, zippers, and other supplies in bulk, they often get a better price. Imagine going to a store and buying one candy bar versus buying a whole box. That box usually costs less per candy! This is how buying in bulk helps factories save money on materials.

Efficient Workflows

Another smart trick is organizing the work in a way that makes everything run smoothly. Factories plan the steps of making swimwear carefully. Each worker knows their job and when to do it. This helps to avoid wasting time and materials. When everyone works together efficiently, it lowers the production costs and keeps things moving fast.

Using Machines

Factories also use machines to help make swimwear. Machines can sew, cut, and even check the quality of the fabric. They can do these jobs faster and sometimes cheaper than people can. This means that the factory can produce more swimsuits in less time. By using machines, factories can keep costs down and still make high-quality swimwear.

Supply Chain Management

Supply chain management is a big part of how swimwear factories in China work. It involves getting all the pieces and materials needed to make swimwear and making sure the finished products reach stores. Let’s look at how this all happens!

Sourcing Materials

First, factories need to find the right materials to make swimwear. They carefully choose from different suppliers to get the best fabrics, zippers, and other items. This is called sourcing materials. Factories look for places that offer good quality at a reasonable price. By doing this, they can keep costs lower and make sure the swimwear is comfy and durable.

Shipping and Delivery

Once the swimwear is made, it needs to get to stores around the world. This is where shipping and delivery come in. Factories work with shipping companies to transport the finished swimwear. They use trucks, ships, and planes to move the swimwear to different countries. Getting these items delivered on time is important so that stores have swimwear ready for customers when they want to buy it.

Inventory Management

Another important part of supply chain management is inventory management. Factories must keep track of all their materials and the swimwear they have made. This means they need to know how much fabric is left and how many swimsuits are ready to be sent out. Good inventory management helps factories make sure they don’t run out of materials, and it also helps them plan for busy times when they need to make more swimwear quickly.

Quality Control

Quality control is super important in a swimwear factory in China. It makes sure that every swimsuit is made well and is safe to wear. If the quality isn't good, customers might not like the swimwear or even get hurt. So, factories have steps to check the quality of their products.

Inspecting the Swimwear

One of the first things that happens in quality control is inspecting the swimwear. After the swimsuits are made, workers look at each piece closely. They check for any mistakes, like loose threads or uneven stitching. If something is not right, it gets fixed right away. This way, only the best swimwear goes out to stores.

Testing the Materials

Another part of quality control is testing the materials used to make the swimwear. Factories want to make sure that the fabric is strong and can last through many swims. They might pull on the fabric to see how stretchy it is or check if it will fade in the sun. By testing the materials, factories can be sure they are making comfortable and durable swimsuits.

Making Improvements

After checking the quality, factories also think about how they can make their swimwear even better. They look at any problems found during inspections or tests. If workers notice that a certain type of fabric doesn't hold up well, the factory may decide to use a different one. Learning from these quality checks helps factories keep improving their swimwear for everyone.

Conclusion

In this article, we explored the fascinating world of swimwear production at a swimwear factory in China. We learned that the manufacturing process involves several important steps, from designing the swimwear to cutting, sewing, and adding special details. Each part of this process is carefully planned to ensure that the final product is both beautiful and functional.

Managing production costs is another key aspect. Factories in China utilize smart strategies to keep costs low. This includes buying materials in bulk, organizing workflows efficiently, and using machines that can work faster than humans. These cost-effective methods help keep the prices of swimwear affordable for everyone.

The next part we discussed was supply chain management. This is all about how factories get the materials they need and send out the finished swimwear. Factories carefully choose where to source their materials from and have effective shipping and delivery methods to reach stores around the globe. They also keep a close eye on their inventory to make sure everything runs smoothly.

Lastly, we looked at quality control. It is crucial for factories to check the quality of their swimwear. They inspect each piece and test the materials to ensure everything meets high standards. By making improvements based on these checks, factories can continue to enhance the quality of their products.

Overall, understanding the swimwear production process in China helps us appreciate the effort that goes into creating the swimwear we enjoy. From the design to the final product, each step is important in making sure that we get swimwear that looks good, feels good, and lasts a long time.

Frequently Asked Questions (FAQs)

Why is swimwear made in China?

Many factories in China are chosen to make swimwear because they can produce it at a lower cost. The country has a lot of experience in making clothes, including swimwear. This experience helps them work faster and better. Also, the factories have access to many materials and skilled workers. This is why many brands decide to use a swimwear factory China for their production needs.

How do factories keep production costs low?

Factories keep production costs low by using smart methods. One way is by buying materials in bulk. When they buy a large amount of fabric and other supplies at once, they can get a better price. Factories also organize their work efficiently. This means they plan everything carefully to save time and money. Lastly, they use machines that can perform tasks quicker and cheaper than people. All these strategies help in managing production costs effectively.

What quality checks are done on swimwear?

Quality control is super important for swimwear. Factories do many checks to ensure their products are good quality. First, workers inspect each piece of swimwear to make sure it is made well and looks nice. They also test the materials used to make sure they are safe and durable. If any issues are found, factories make improvements to fix them. This process helps ensure that the swimwear is comfortable and will last a long time.