Content Menu

● Introduction

● Key Steps in Custom Swimwear Manufacturing

>> Design Phase

>> Material Selection

>> Production Phase

>> Quality Control

>> Packaging and Shipping

● Factors Affecting Custom Swimwear Manufacturing Time

● How to Shorten Delivery Time for Custom Swimwear

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical timeline for custom swimwear manufacturing?

>> 2. How can I ensure my custom swimwear is produced on time?

>> 3. What factors can delay the manufacturing process?

>> 4. Can I make changes to my design after production has started?

>> 5. What types of materials are commonly used in custom swimwear?

Introduction

In recent years, the demand for custom swimwear has surged, driven by the growing popularity of personalized fashion and the need for unique designs that cater to individual preferences. As a custom swimwear factory, we understand the importance of delivering high-quality products that meet the specific needs of our clients, including swimwear brands, wholesalers, and manufacturers worldwide. This article will explore the entire process of custom swimwear manufacturing, from design to delivery, and provide insights into the timeframes involved.

Key Steps in Custom Swimwear Manufacturing

Design Phase

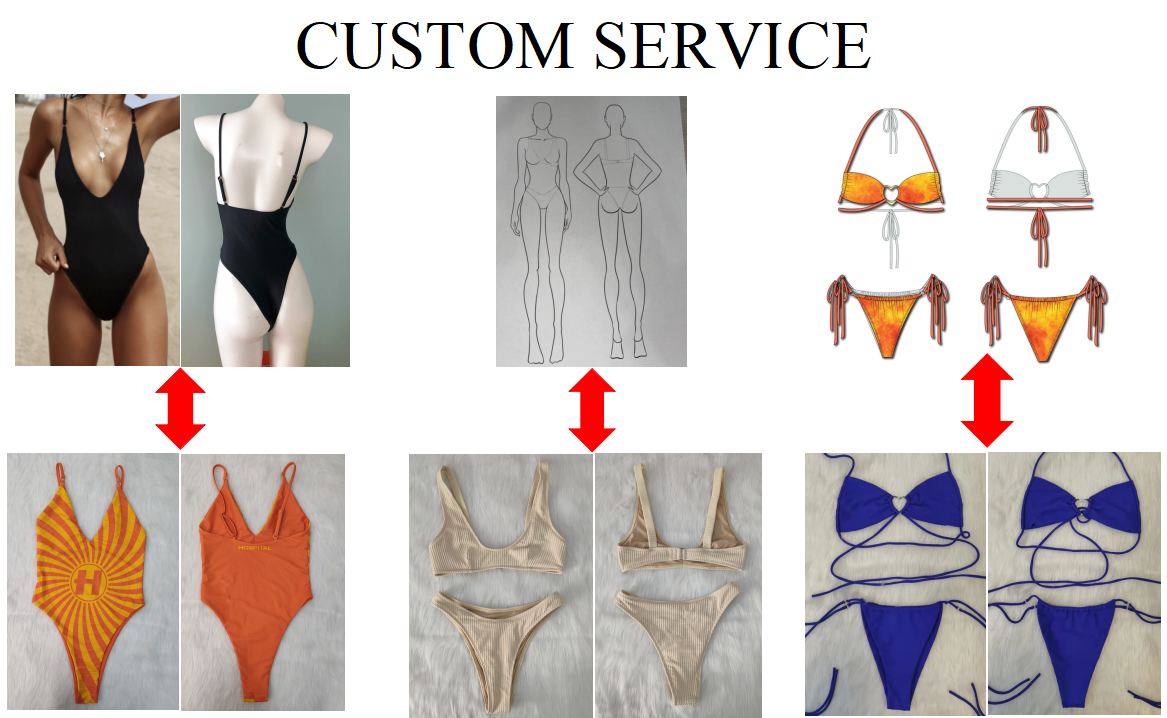

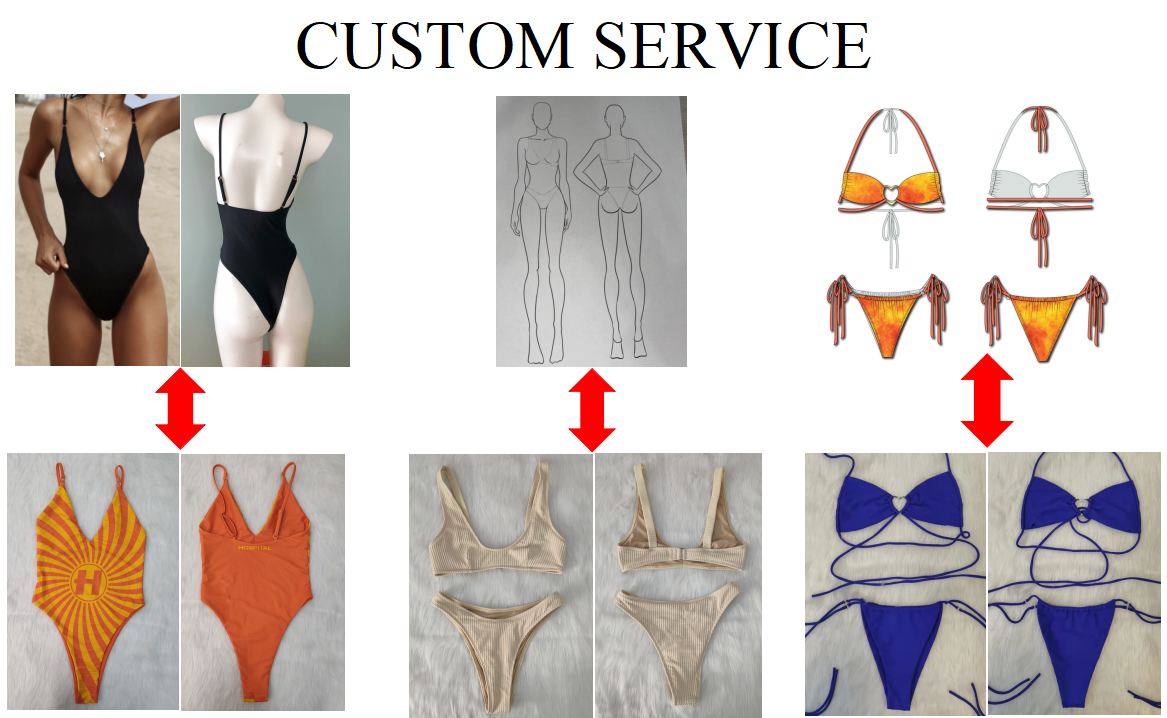

The design phase is the foundation of the custom swimwear manufacturing process. It begins with a thorough analysis of customer requirements. Our team collaborates closely with clients to understand their vision, target audience, and specific design elements they wish to incorporate. This stage is crucial, as it sets the direction for the entire project.

Once we have a clear understanding of the client's needs, we move on to sketching designs and creating samples. Our skilled designers utilize advanced software to create detailed digital mock-ups, allowing clients to visualize their swimwear before production begins. This iterative process often involves several rounds of feedback and revisions, ensuring that the final design aligns perfectly with the client's expectations.

Material Selection

After finalizing the design, the next step is material selection. As a custom swimwear factory, we offer a wide range of high-quality fabrics and accessories suitable for swimwear production. The choice of materials significantly impacts the overall look, feel, and performance of the swimwear.

During this phase, we work closely with our clients to select the most appropriate fabrics, considering factors such as durability, stretchability, and colorfastness. Additionally, we ensure that the materials comply with industry standards and regulations. The procurement of materials can take anywhere from a few days to several weeks, depending on the availability of the chosen fabrics.

Production Phase

Once the materials are secured, we move into the production phase. This stage involves several key steps:

- Production Planning: Our production team develops a detailed plan that outlines the timeline, resources, and workforce required for manufacturing the swimwear. This plan is crucial for ensuring that we meet delivery deadlines.

- Production Line Setup: Setting up the production line involves organizing the workflow, machinery, and equipment needed for efficient manufacturing. Our custom swimwear factory is equipped with state-of-the-art technology that enhances productivity and quality.

- Production Time Estimation: The time required for production varies based on the complexity of the designs and the quantity ordered. Simple designs may take a few days to produce, while more intricate styles could take several weeks.

Quality Control

Quality control is an integral part of the custom swimwear manufacturing process. Throughout production, we conduct regular quality checks to ensure that each piece meets our high standards. This includes inspecting the stitching, fabric quality, and overall construction of the swimwear.

At the end of the production run, we perform a final inspection of the finished products. This step is essential to identify any defects or inconsistencies before the swimwear is packaged and shipped. Our commitment to quality ensures that clients receive only the best products from our custom swimwear factory.

Packaging and Shipping

Once the swimwear has passed quality control, we move on to packaging and shipping. Packaging design is an important aspect of the process, as it not only protects the products during transit but also enhances the brand's image. We offer customized packaging solutions that reflect the client's branding and marketing strategies.

After packaging, we arrange logistics for shipping the swimwear to our clients. This involves selecting the most efficient shipping methods and coordinating with logistics partners to ensure timely delivery. The shipping time can vary based on the destination and chosen shipping method, but we strive to provide our clients with accurate estimates to manage their expectations.

Factors Affecting Custom Swimwear Manufacturing Time

Several factors can influence the overall time required for custom swimwear manufacturing:

- Design Complexity: More intricate designs typically require additional time for both the design and production phases. Custom swimwear factories must allocate sufficient time for detailed work to ensure quality.

- Material Supply Chain Stability: The availability of materials can significantly impact production timelines. Delays in sourcing fabrics or accessories can lead to extended manufacturing times.

- Production Capacity and Factory Efficiency: The efficiency of the custom swimwear factory plays a crucial role in determining how quickly orders can be fulfilled. Factories with advanced technology and streamlined processes can often produce swimwear more quickly.

- Customer Feedback and Revision Cycles: The time taken for clients to review designs and provide feedback can also affect the overall timeline. Quick and clear communication can help expedite this process.

How to Shorten Delivery Time for Custom Swimwear

To ensure timely delivery of custom swimwear, clients can take several proactive steps:

- Early Planning and Communication: Engaging with the custom swimwear factory early in the design process allows for better planning and resource allocation. Clear communication about expectations and timelines can help avoid delays.

- Choosing the Right Manufacturing Partner: Selecting a reliable custom swimwear factory with a proven track record can make a significant difference in delivery times. Researching potential partners and their capabilities is essential.

- Utilizing Advanced Manufacturing Technologies: Factories that invest in modern technologies can often produce swimwear more efficiently. Clients should inquire about the manufacturing processes used by their chosen factory.

Conclusion

In summary, the timeline for custom swimwear manufacturing can vary based on several factors, including design complexity, material availability, and production efficiency. By understanding the entire process—from design to delivery—clients can better manage their expectations and work collaboratively with their custom swimwear factory to achieve their goals.

Establishing a strong partnership with a reliable custom swimwear factory is essential for success in this competitive market. By prioritizing communication and planning, clients can ensure that their custom swimwear is delivered on time and meets the highest quality standards.

Frequently Asked Questions

1. What is the typical timeline for custom swimwear manufacturing?

- The timeline can vary widely, but it generally takes anywhere from 4 to 12 weeks from design to delivery, depending on the complexity of the designs and material availability.

2. How can I ensure my custom swimwear is produced on time?

- Early planning, clear communication with your custom swimwear factory, and prompt feedback during the design phase can help ensure timely production.

3. What factors can delay the manufacturing process?

- Delays can occur due to design complexity, material supply chain issues, and extended feedback cycles from clients.

4. Can I make changes to my design after production has started?

- While changes can be made, they may lead to delays and additional costs. It's best to finalize designs before production begins.

5. What types of materials are commonly used in custom swimwear?

- Common materials include nylon, polyester, spandex, and various blends that offer durability, stretch, and comfort for swimwear.